Checking tool suitable for car door skeleton

A skeleton and inspection tool technology, applied in the direction of using mechanical devices, measuring devices, instruments, etc., can solve the problems of high labor intensity, difficulty and inaccurate measurement of operators, so as to improve work efficiency, improve accuracy, and improve stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

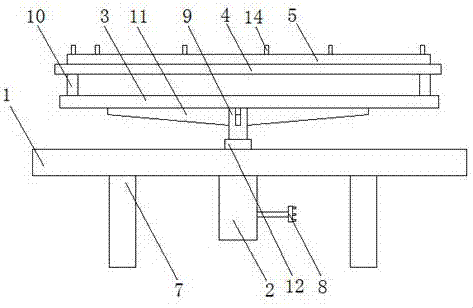

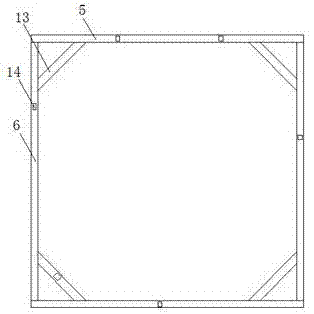

[0016] as attached figure 1 with 2 As shown, a checker suitable for a car door frame includes a base plate 1, a cylinder 2, a connecting plate 3, a positioning plate 4, a cross bar 5 and a longitudinal bar 6, and it is characterized in that: the base plate 1 is arranged on a bracket 7, Described cylinder 2 is arranged on the bottom plate 1, and is provided with power line 8, piston rod 9 on cylinder 2, and described connecting plate 3 is arranged on the piston rod 9, and is provided with connecting rod 10 on connecting plate 3 , the positioning plate 4 is arranged on the connecting rod 10, the cross bar 5 is arranged on the positioning plate 4, the longitudinal bar 6 is arranged on the positioning plate 4, and the vertical bar 6 is vertically connected with the cross bar 5 , and a reinforcement bar 13 is arranged between the cross bar 5 and the longitudinal bar 6, the cross bar 5 and the longitudinal bar 6 are all arranged on the positioning plate 4, the longitudinal bar 6 is...

Embodiment 2

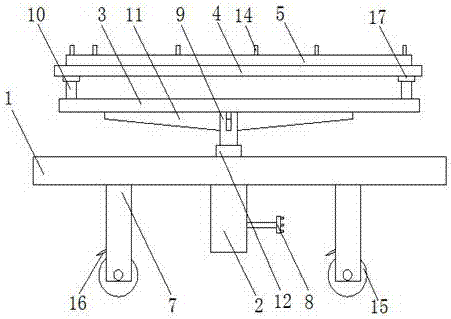

[0021] as attached image 3 As shown, a checker suitable for a car door frame includes a base plate 1, a cylinder 2, a connecting plate 3, a positioning plate 4, a cross bar 5 and a longitudinal bar 6, and it is characterized in that: the base plate 1 is arranged on a bracket 7, Described cylinder 2 is arranged on the bottom plate 1, and is provided with power line 8, piston rod 9 on cylinder 2, and described connecting plate 3 is arranged on the piston rod 9, and is provided with connecting rod 10 on connecting plate 3 , the positioning plate 4 is arranged on the connecting rod 10, the cross bar 5 is arranged on the positioning plate 4, the longitudinal bar 6 is arranged on the positioning plate 4, and the vertical bar 6 is vertically connected with the cross bar 5 , and a reinforcement bar 13 is arranged between the cross bar 5 and the longitudinal bar 6, the cross bar 5 and the longitudinal bar 6 are all arranged on the positioning plate 4, the longitudinal bar 6 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com