Fabricated inverted arch and manufacturing method thereof

A manufacturing method and assembly-type technology, which is applied in shaft equipment, earthwork drilling, wellbore lining, etc., can solve problems such as unsuitable tunnels, and achieve the effects of being conducive to structural stress, reducing costs, and facilitating production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

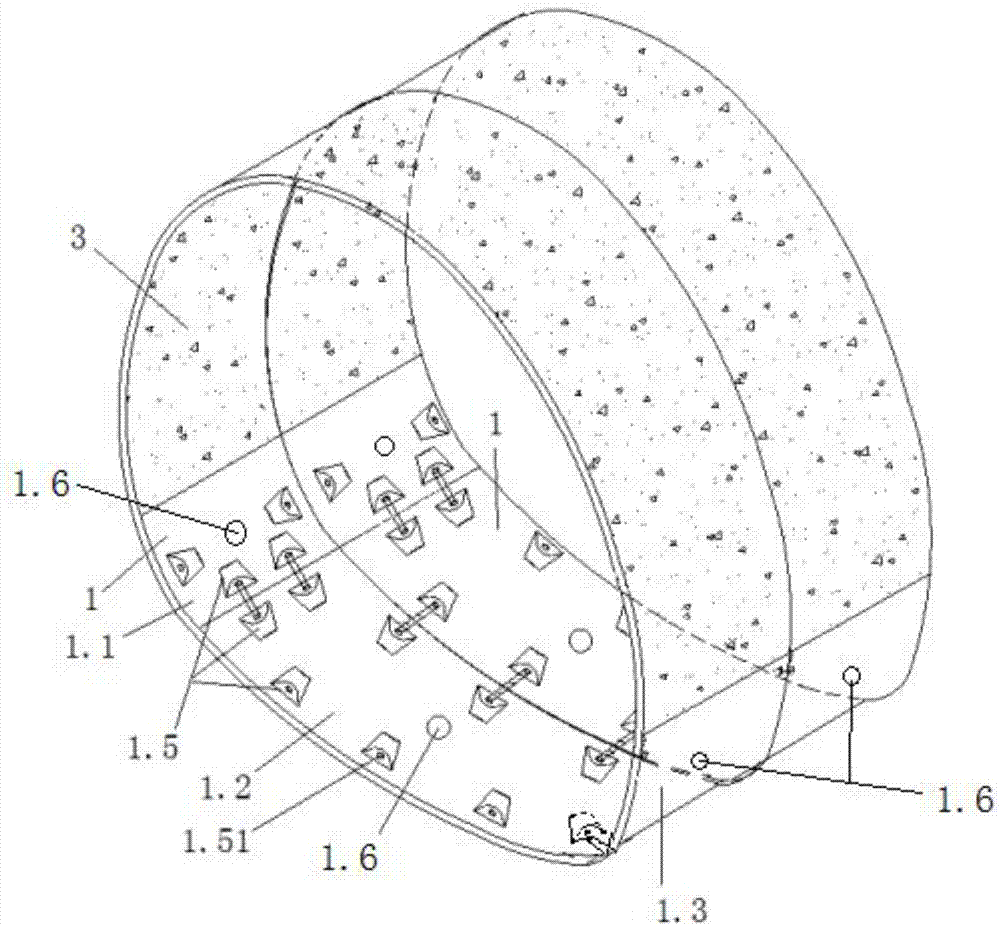

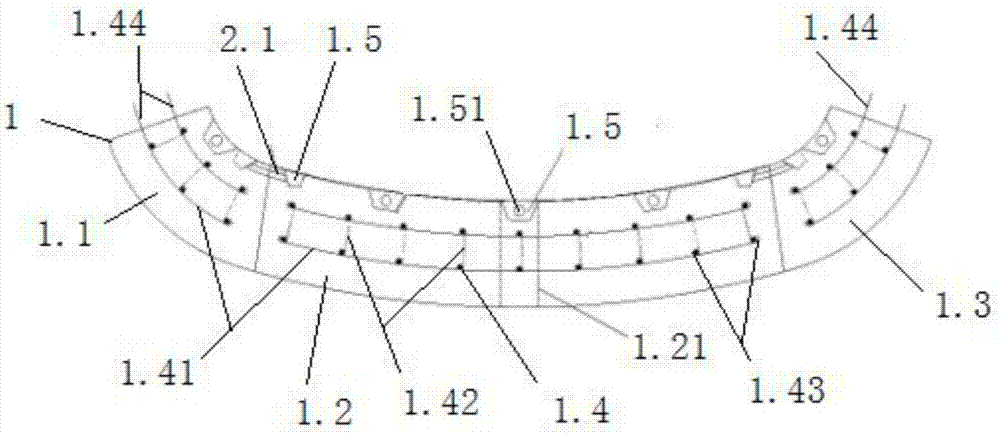

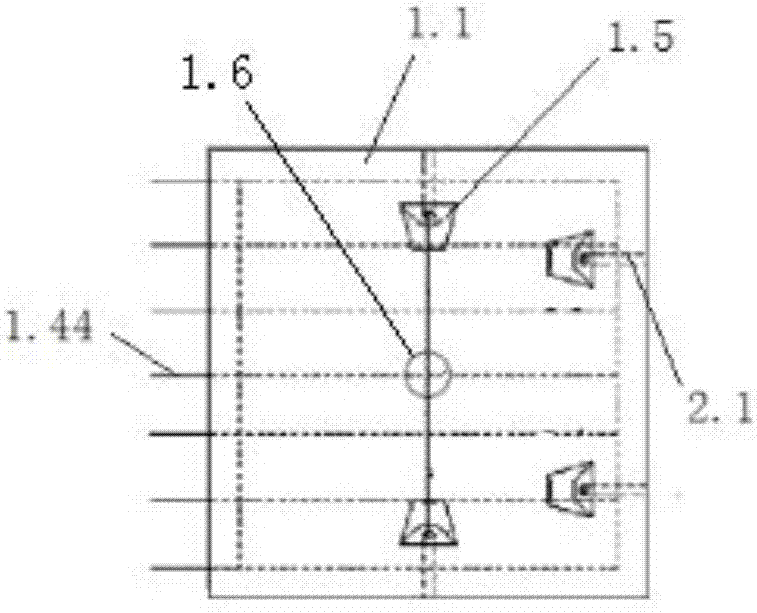

[0049] A prefabricated inverted arch, see Figure 1-Figure 5 , including two sections of detachably connected inverted arch monomer 1, the inverted arch monomer includes a first section 1.1, a second section 1.2 and a first section 1.1 detachably connected by a detachable connecting piece 2 along its width direction. Three sections 1.3, the detachable connector 2 includes bolts 2.1, between the first section 1.1 and the second section 1.2, between the second section 1.2 and the third section 1.3 and adjacent Both groups of inverted arch monomers 1 are connected through the detachable connecting piece 2 .

[0050] The first section 1.1 and the third section 1.3 have the same structure and can be combined into one category for batch production.

[0051] The position where the bending moment at the junction of the first section 1.1 and the second section 1.2 and the junction of the second section 1.2 and the third section 1.3 is zero, where the unit of the bending moment is kN· ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com