Preparation method of dual-scale titanium alloy material

A titanium alloy, two-scale technology, applied in the field of metallurgy, can solve the problems of difficult to control the grain size of products, long preparation time, high porosity, improve the density and mechanical properties, uniform grain distribution, and concise production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

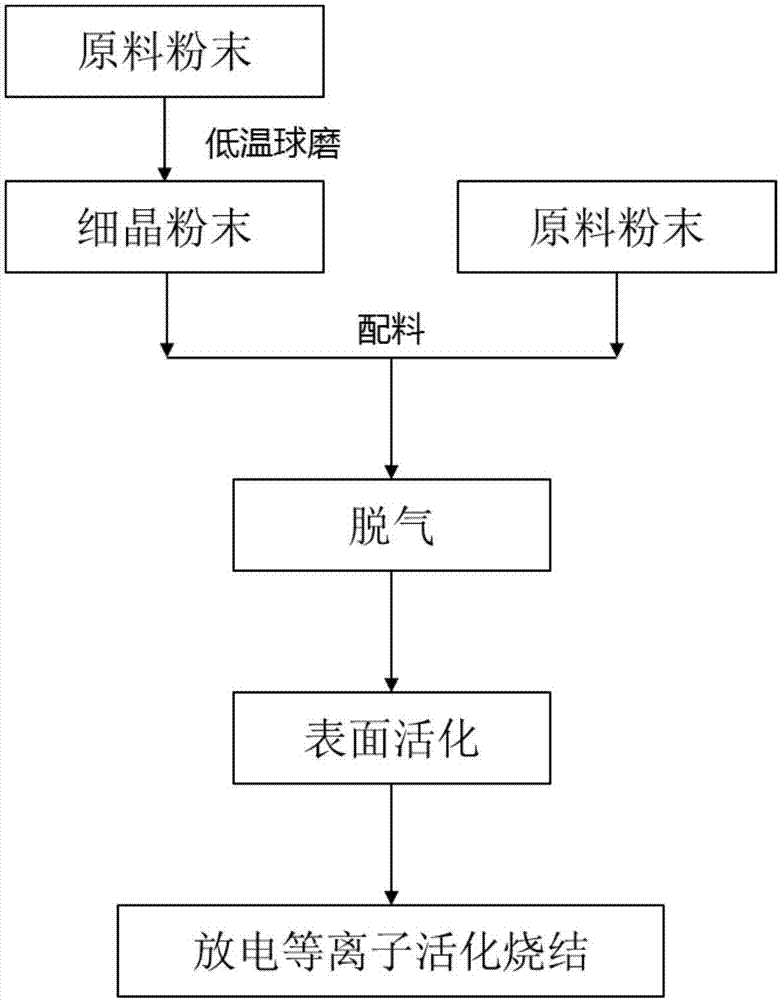

Method used

Image

Examples

Embodiment 1

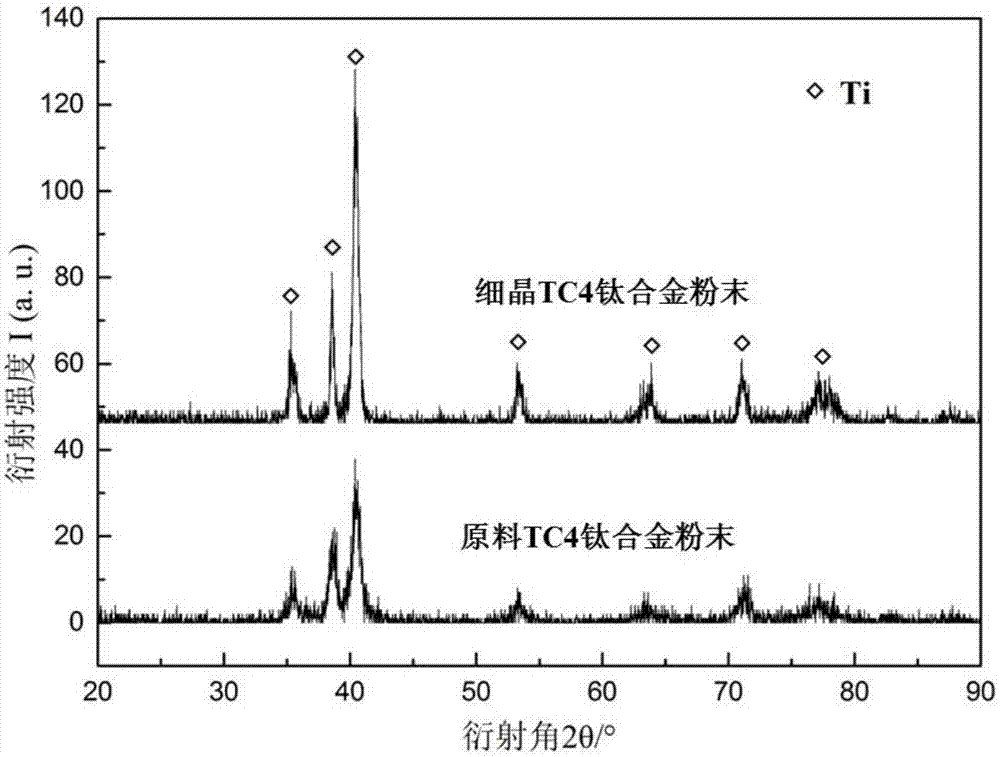

[0031] The preparation process of the experimental fine-grained powder is as follows: on a low-temperature ball mill, liquid N 2 As the medium, ball milled at 600 rpm for 4 hours to obtain fine-grained powder. The XRD comparison patterns of the raw material TC4 titanium alloy powder and the fine-grained TC4 titanium alloy powder prepared by low temperature ball milling are as follows: figure 2 shown.

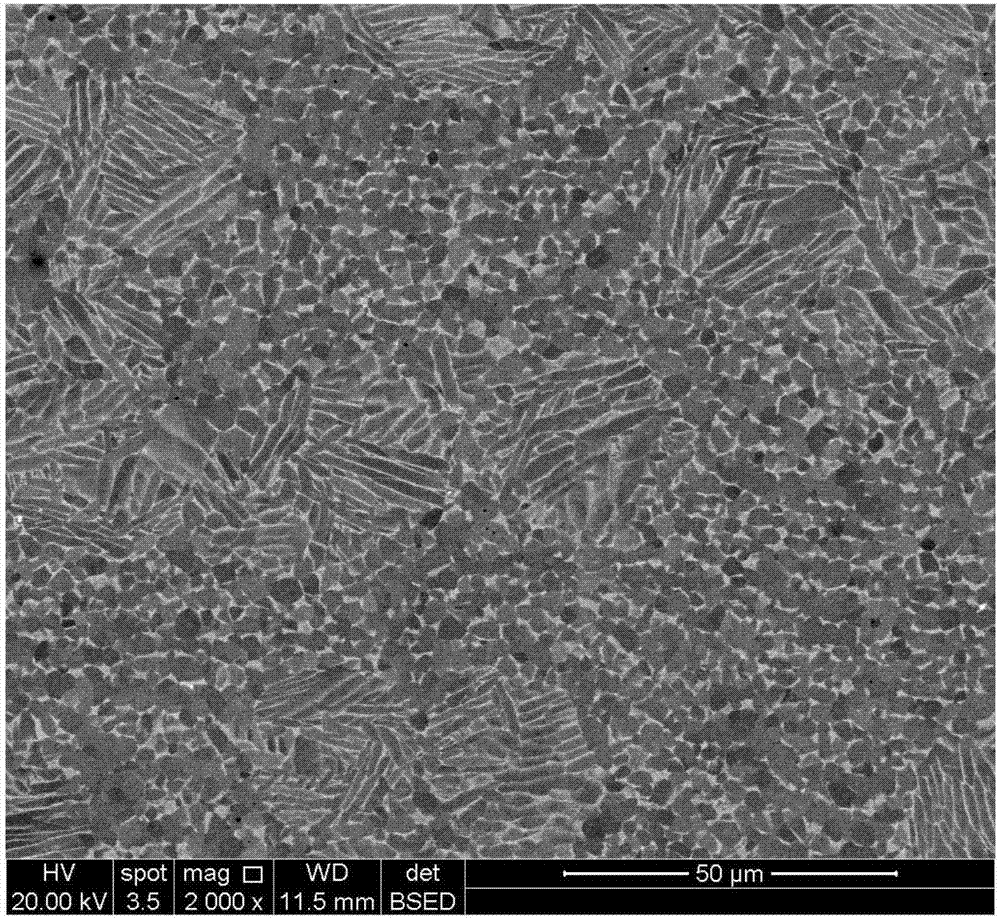

[0032] The composition ratio of the experimental double-scale titanium alloy material is: by mass, the coarse-grained TC4 alloy powder is 95%, the fine-grained powder is 5%, and the mixed powder is obtained by ball milling at a speed of 300 rpm on a planetary ball mill for 2 hours. The material body is degassed in a vacuum hot-press furnace with a heating rate of 10°C / min, without pressure, and heated to 350°C for 10 hours. After degassing, the surface is activated in a plasma activation sintering furnace. The surface activation time is 30s. The activation voltage is 20kV, th...

Embodiment 2

[0035] The preparation process of the experimental fine-grained powder is as follows: on a low-temperature ball mill, liquid N 2 As the medium, ball milled at 600 rpm for 4 hours to obtain fine-grained powder. The composition ratio of the experimental dual-scale titanium alloy material is: by mass, the coarse-grained TC4 alloy powder is 75%, the fine-grained powder is 25%, and the mixed powder is obtained by ball milling at a speed of 300 rpm on a planetary ball mill for 2 hours. The material body is degassed in a vacuum hot-press furnace with a heating rate of 10°C / min, without pressure, and heated to 350°C for 10 hours. After degassing, the surface is activated in a plasma activation sintering furnace. The surface activation time is 30s. The activation voltage is 20kV, the activation current is 100A, the vacuum degree is ≤10Pa, the temperature rises rapidly after surface activation, the heating rate is 100°C / min, the pressure is 20MPa, the temperature is raised to 900°C and ...

Embodiment 3

[0038] The preparation process of the experimental fine-grained powder is as follows: on a low-temperature ball mill, liquid N 2 As the medium, ball milled at 600 rpm for 4 hours to obtain fine-grained powder. The composition ratio of the experimental double-scale titanium alloy material is: by mass, the coarse-grained TC4 alloy powder is 50%, the fine-grained powder is 50%, and the mixed powder is obtained by ball milling at a speed of 300 rpm on a planetary ball mill for 2 hours. The material body is degassed in a vacuum hot-press furnace with a heating rate of 10°C / min, without pressure, and heated to 350°C for 10 hours. After degassing, the surface is activated in a plasma activation sintering furnace. The surface activation time is 30s. The activation voltage is 20kV, the activation current is 100A, the vacuum degree is ≤10Pa, the temperature rises rapidly after surface activation, the heating rate is 100°C / min, the pressure is 20MPa, the temperature is raised to 900°C an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness value | aaaaa | aaaaa |

| Compressive yield strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com