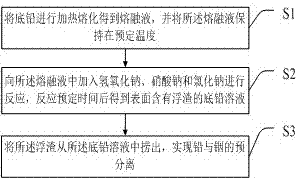

Method for pre-separating lead and indium from bottom lead

A technology of pre-separation and lead solution, applied in the field of indium, pre-separation of lead from bottom lead, can solve the problems of waste of resources and high recovery cost of bottom lead and lead, and achieve the effect of solving the waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Put 1 ton of bottom lead into the melting furnace, raise the temperature to 500°C, melt all the bottom lead to obtain a molten liquid, control the temperature of the molten liquid at 400°C, and slowly add sodium hydroxide to the molten liquid while stirring 200kg, sodium nitrate 100kg, sodium chloride 50kg, after 4 hours of reaction, remove the scum on the upper layer of the bottom lead solution to realize the pre-separation of lead and indium. At this time, the indium remaining in the molten liquid accounted for 1% of the total indium amount.

Embodiment 2

[0039] Add 1 ton of bottom lead into the melting furnace, raise the temperature to 510°C, melt all the bottom lead to obtain a molten liquid, control the temperature of the molten liquid at 430°C, and slowly add sodium hydroxide to the molten liquid while stirring 220kg, 130kg of sodium nitrate, and 80kg of sodium chloride. After reacting for 5 hours, remove the scum on the upper layer of the bottom lead solution to realize the pre-separation of lead and indium. At this time, the indium remaining in the molten liquid accounted for 0.7% of the total indium amount.

Embodiment 3

[0041] Add 1 ton of bottom lead into the melting furnace, raise the temperature to 520°C, melt all the bottom lead to obtain a molten liquid, control the temperature of the molten liquid at 450°C, and slowly add sodium hydroxide to the molten liquid while stirring 250kg, 150kg of sodium nitrate, and 100kg of sodium chloride. After 6 hours of reaction, remove the scum on the upper layer of the bottom lead solution to realize the pre-separation of lead and indium. At this time, the indium remaining in the molten liquid accounted for 0.5% of the total indium amount.

[0042] In summary, the present invention adopts that the bottom lead is melted at a high temperature, and sodium hydroxide, sodium nitrate and sodium chloride are added to the melted bottom lead to react to oxidize metal indium into sodium indium acid (Na 3 InO 3 ), at this time, sodium indium is dissolved in the solution of sodium hydroxide and sodium chloride to form scum and separate from lead, and the obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com