Civil air defense door coating and preparation method thereof

A technology for civil air defense doors and coatings, which is applied in the direction of antifouling/underwater coatings, coatings, paints containing biocides, etc., which can solve the problem of affecting the appearance and service life of civil air defense doors, civil air defense doors without waterproof and moisture resistance, and yellowing of the door body surface Mildew and other problems, to achieve the effect of strong and durable layers, low equipment requirements, and strong moisture and mildew resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

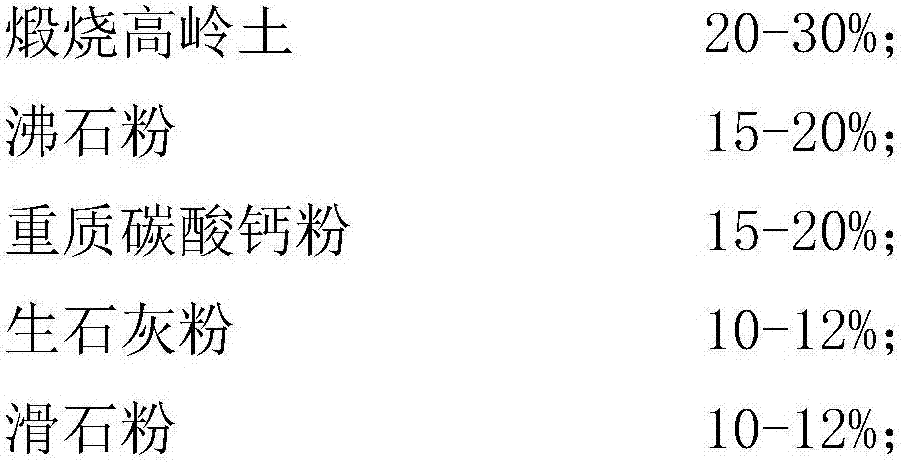

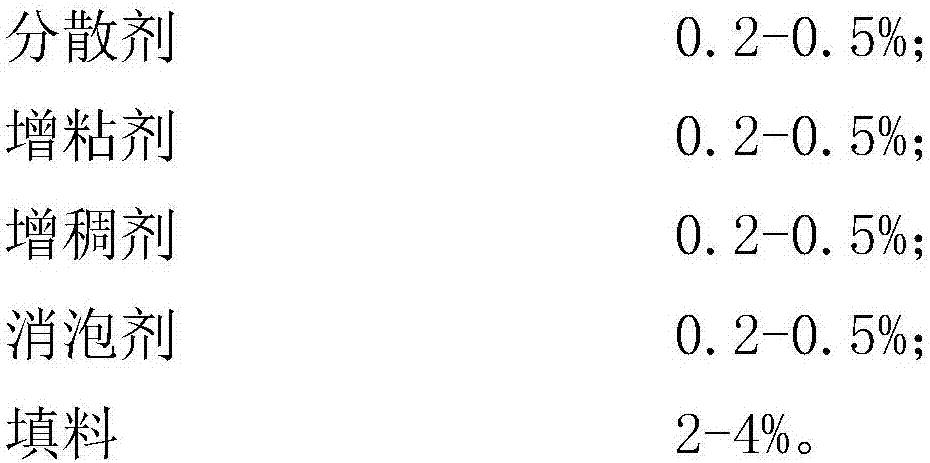

[0025] A kind of fireproof door coating, comprises A and B two groups of components, the mass ratio of its A component and B component is 50:(1-3), and described A component is by weight percentage, comprises following material:

[0026]

[0027] The B component includes the following substances in weight percent:

[0028]

[0029] The dispersant is one or both of sodium pyrophosphate and sodium hexametaphosphate.

[0030] The tackifier is one or both of epoxy resin and rosin glyceride.

[0031] The thickener is microporous starch.

[0032] The defoamer is an inorganic defoamer.

[0033] The filler is one or both of inorganic bentonite and attapulgite.

[0034] The present invention also provides a kind of preparation method of civil air defense door coating, comprises steps:

[0035] 1) Grinding calcined kaolin, zeolite powder, heavy calcium carbonate powder, quicklime powder, and talcum powder with a pulverizer to a particle size of less than or equal to 60 mesh, a...

Embodiment 2

[0040] A kind of civil air defense door coating, comprises A and B two groups of components, and the mass ratio of its A component and B component is 50:1, and described A component is by weight percentage, comprises following material:

[0041]

[0042] The B component includes the following substances in weight percent:

[0043]

[0044] The dispersant is one or both of sodium pyrophosphate and sodium hexametaphosphate.

[0045] The tackifier is one or both of epoxy resin and rosin glyceride.

[0046] The thickener is microporous starch.

[0047] The defoamer is an inorganic defoamer.

[0048] The filler is one or both of inorganic bentonite and attapulgite.

[0049] The present invention also provides a kind of preparation method of civil air defense door coating, comprises steps:

[0050] 1) Grinding calcined kaolin, zeolite powder, heavy calcium carbonate powder, quicklime powder, and talcum powder with a pulverizer to a particle size of less than or equal to 60...

Embodiment 3

[0055] A kind of fireproof door coating, comprises A and B two groups of components, the mass ratio of its A component and B component is 50:(1-3), and described A component is by weight percentage, comprises following material:

[0056]

[0057] The B component includes the following substances in weight percent:

[0058]

[0059] The dispersant is one or both of sodium pyrophosphate and sodium hexametaphosphate.

[0060] The tackifier is one or both of epoxy resin and rosin glyceride.

[0061] The thickener is microporous starch.

[0062] The defoamer is an inorganic defoamer.

[0063] The filler is one or both of inorganic bentonite and attapulgite.

[0064] The present invention also provides a kind of preparation method of civil air defense door coating, comprises steps:

[0065] 1) Grinding calcined kaolin, zeolite powder, heavy calcium carbonate powder, quicklime powder, and talcum powder with a pulverizer to a particle size of less than or equal to 60 mesh, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com