Process for producing carboxylic acrylonitrile butadiene rubber latex

A carboxylated nitrile latex and production process technology, applied in the field of polymer chemical material production, can solve the problems of complicated addition of monomers, complex process operation, difficult control of reaction temperature, etc., and achieve low production cost, excellent comprehensive performance, easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

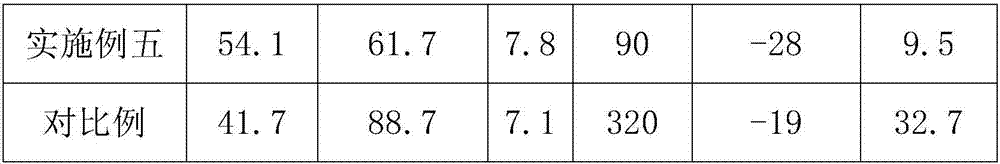

Examples

Embodiment 1

[0025] A kind of production technology of carboxylated nitrile latex proposed by the present invention comprises the following steps:

[0026] S1. Weigh the raw materials, including 96 parts of deionized water, 1.8 parts of molecular weight regulator, 0.4 parts of pH buffer and 4.5 parts of emulsifier, add the above raw materials into the polymerization kettle, at a temperature of 42 ° C, at 700 r / min Stir at a high speed for 1.8h, after mixing evenly, vacuumize with nitrogen; wherein the molecular weight regulator is n-dodecyl mercaptan; the pH buffer is potassium hydrogen phthalate and mixed phosphate with a mass ratio of 1.6:1.1:9.6 and distilled water; the emulsifier is sodium dodecylbenzenesulfonate, rosin oil soap, sorbitan trioleate and propylene glycol monostearate with a mass ratio of 2.6:2.5:1.6:3.5 Compounding agent;

[0027] S2. Weigh raw materials, including 48 parts of butadiene, 28 parts of acrylonitrile, 14 parts of acrylic acid monomer and 4.5 parts of unsatu...

Embodiment 2

[0031] A kind of production technology of carboxylated nitrile latex proposed by the present invention comprises the following steps:

[0032] S1. Weigh the raw materials, including 75 parts of deionized water, 1 part of molecular weight modifier, 0.1 part of pH buffer and 3 parts of emulsifier, add the above raw materials into the polymerization kettle, at a temperature of 28 ° C, at 550 r / min Stir at a high speed for 1h, after mixing evenly, vacuumize with nitrogen filling; wherein the molecular weight regulator is n-dodecyl mercaptan; the pH buffering agent is potassium hydrogen phthalate, mixed phosphate and Compounding agent of distilled water; emulsifier is a compounding agent of sodium dodecylbenzenesulfonate, rosin oil soap, sorbitan trioleate and propylene glycol monostearate with a mass ratio of 2.2:1:1.2:2 Dispensing;

[0033] S2. Weigh raw materials, including 38 parts of butadiene, 20 parts of acrylonitrile, 8 parts of acrylic acid monomer and 2 parts of unsatura...

Embodiment 3

[0037] A kind of production technology of carboxylated nitrile latex proposed by the present invention comprises the following steps:

[0038] S1. Weigh the raw materials, including 88 parts of deionized water, 1.5 parts of molecular weight regulator, 0.3 parts of pH buffer and 4 parts of emulsifier, add the above raw materials into the polymerization kettle, at the temperature of 28 ~ 45 ℃, at 650r Stir for 1.5h at a speed of 1 / min, after mixing evenly, vacuumize with nitrogen; wherein the molecular weight regulator is n-dodecyl mercaptan; the pH buffer is potassium hydrogen phthalate with a mass ratio of 1.6:1:8.8, mixing Compounding agent of phosphate and distilled water; emulsifier is sodium dodecylbenzenesulfonate, rosin oil soap, sorbitan trioleate and propylene glycol monostearate with a mass ratio of 2.5:2:1.5:3 ester compounding agent;

[0039] S2. Weigh raw materials, including 44 parts of butadiene, 25 parts of acrylonitrile, 12 parts of acrylic acid monomer and 3....

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com