Method for adjusting oxygen balance of energy-containing material based on emulsion method

A technology of oxygen balance and emulsion method, which is applied in the production of bulk chemicals, explosives processing equipment, ammonium perchlorate composition, etc., can solve the problems of poor safety, difficulty in mass production, and long cycle, and achieve improved safety performance and energy efficiency. Enhanced, milder effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

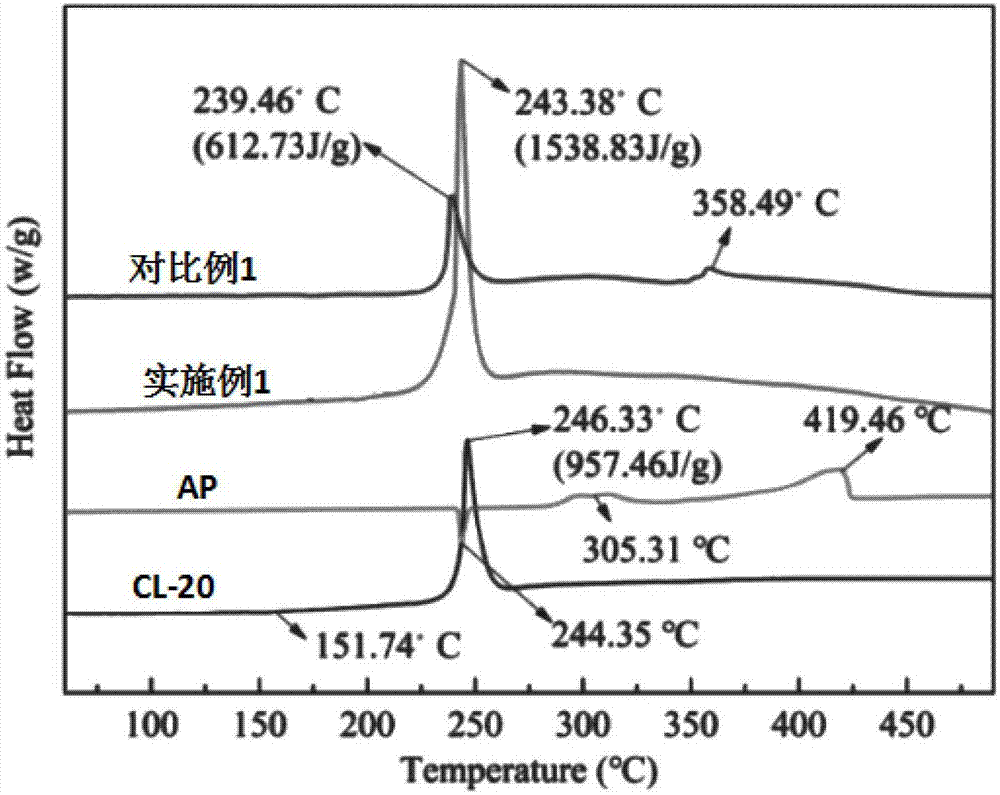

Embodiment 1

[0030] A method for adjusting the oxygen balance of energetic materials based on the emulsion method includes the following steps:

[0031] Step 1. According to the principle of zero oxygen balance, 0.35g of hexanitrohexaazaisopentane is dissolved in 5mL ethyl acetate to obtain a solution of hexanitrohexaazaisopentane; 0.144g of high chlorine Ammonium acid was dissolved in 20 mL of distilled water to obtain ammonium perchlorate solution;

[0032] Step 2. At 25℃, mix the hexanitrohexaazaisopentane solution and ammonium perchlorate solution and stir at constant temperature, then add the surfactant Tween-80, and stir at 25℃ until a suspension is formed , A uniform emulsion is formed after 10 minutes of ultrasound; the added amount of the surfactant Tween-80 is 0.5% of the total mass of the energetic material and the oxidant;

[0033] Step 3. Take the emulsion out immediately and put it in a freezer at -50℃ to make it solidify quickly, and place it in a freeze dryer to dry for 28 hours ...

Embodiment 2

[0035] A method for adjusting the oxygen balance of energetic materials based on the emulsion method includes the following steps:

[0036] Step 1. Dissolve 0.35g of hexanitrohexaazaisopentane in 5mL ethyl acetate to obtain a hexanitrohexaazaisopentane solution; dissolve 0.25g of ammonium nitrate in 20mL of distilled water to obtain nitric acid Ammonium solution

[0037] Step 2. At 25°C, mix the hexanitrohexaazaisopentane solution and ammonium nitrate solution and stir at constant temperature, then add the surfactant Tween-80, stir at 25°C until a suspension is formed, ultrasonic A uniform emulsion is formed after 10 minutes; the added amount of the surfactant Tween-80 is 0.35% of the total mass of the energetic material and the oxidant;

[0038] Step 3. Take the emulsion out immediately and put it in a freezer at -50℃ to make it solidify quickly, and place it in a freeze dryer to dry for 48 hours to obtain a hexanitrohexaazaisopentazidine / ammonium nitrate composite energy-containin...

Embodiment 3

[0040] A method for adjusting the oxygen balance of energetic materials based on the emulsion method includes the following steps:

[0041] Step 1. Dissolve 0.4g TNT in 3mL acetone to obtain a TNT solution; dissolve 0.87g ammonium perchlorate in 25mL distilled water to obtain an ammonium perchlorate solution;

[0042] Step 2. Mix the TNT solution and the ammonium perchlorate solution at 25°C and stir at constant temperature, then add the surfactant Tween-80, and stir at 25°C until a suspension is formed. After 10 minutes of sonication, a homogeneous emulsion is formed; The added amount of the surfactant Tween-80 is 0.5% of the total mass of the energetic material and the oxidant;

[0043] Step 3. Take the emulsion out immediately and put it in a freezer at -50℃ to make it solidify quickly, and place it in a freeze dryer to dry for 48 hours to obtain a hexanitrohexaazaisopentazidine / ammonium nitrate composite energy-containing compound with adjusted oxygen balance material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com