3D printing method for printing colorful models

A 3D printing and model technology, applied in the field of 3D printing, can solve the problems of a single color matching form, a large amount of calculation, and a small amount of resources, and achieve the effect of a simple coloring process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

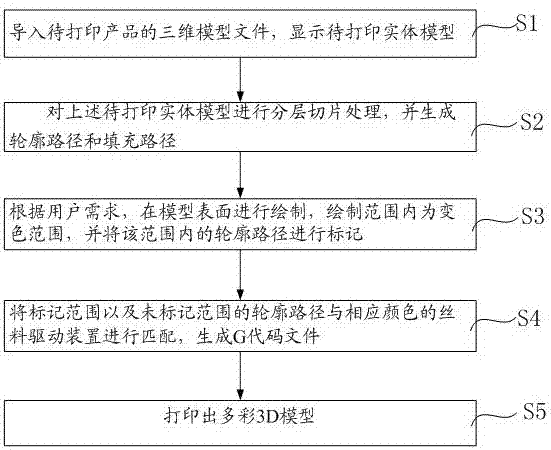

[0046] S1, importing the Stl file into the software to display the solid model;

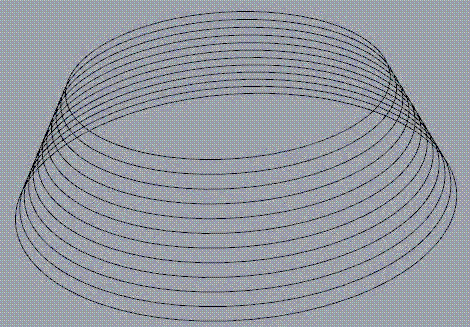

[0047] S2, in the Z-axis direction, slice the solid model, each unit height is one slice, and finally transform the complete solid into an approximate solid stacked by many thin slices, and mark the outline, filling, top surface and bottom surface of each layered slice and other feature information to generate contour paths and fill paths; determine whether support surfaces need to be added, and if so, generate support paths based on the support areas that need to be added.

[0048] In this embodiment, judging whether to add a support surface is realized through the following steps: project the model to the bottom surface, filter out the overhang surface, calculate the inclination angle and span length of each surface, and mark it as a support surface if it exceeds the set critical value.

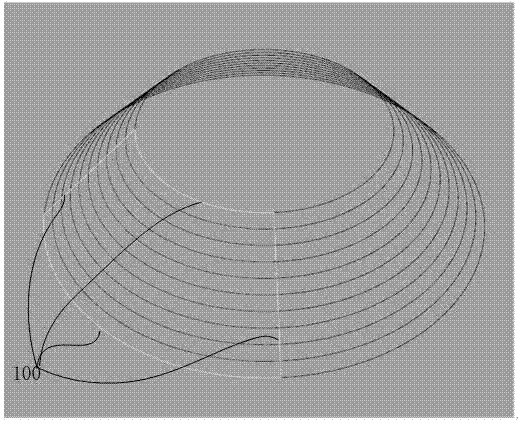

[0049] S3, draw on the surface of the model according to the user's needs, the range of color change is withi...

Embodiment 2

[0075] The drawing process in step S3 and the process of marking the outline path with color will be described below.

[0076] Drawing method one:

[0077] The mouse pointer turns into a round brush (similar to the paintbrush of drawing software, the diameter of the brush can be set) to paint on the surface of the model, and the covered path is marked with color. The color of the brush can be set, and it can be painted multiple times. The last time prevails, the same color part integrates a complete area, and the intersection of the boundary line of the complete area and the model outline path is used as a color-changing node.

[0078] When filtering the intersection point, after multiple times of coloring, the generated nodes inside the same color area will be deleted; the color boundary line is tangent to the model outline path line, an intersection point will be generated, and it will be deleted.

[0079] drawing method two,

[0080] The paintbrush is a point, draws a lin...

Embodiment 3

[0081] Embodiment 3, illustrate with two kinds of color silk material replacement processes below

[0082] E1 is a wire feeding device for conveying white silk, and E2 is a wire feeding device for conveying black silk;

[0083] E1 0 E2 0 (initial, the value of each extrusion head is 0)

[0084] E1 0.56 E2 0 (E1 changes from 0 to 0.56mm, that is, the filament is extruded from E1; if the value of E2 remains unchanged, there is no extrusion action).

[0085] E1 0.56E2 0.23 (the value of E1 remains unchanged, E1 is not extruded; E2 is changed from 0 to 0.23, that is, the length of 0.23 is extruded from E2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com