A polyvinylamine composite functional membrane with lamellar screening channels and its preparation method and application

A technology of polyvinylamine and compound functions, which is applied in the field of chemical engineering gas separation membranes, can solve the problems of poor diffusion performance of small molecule gas and reduce free volume, etc., and achieve the effects of improving CO2 permeability, preventing crystallization, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

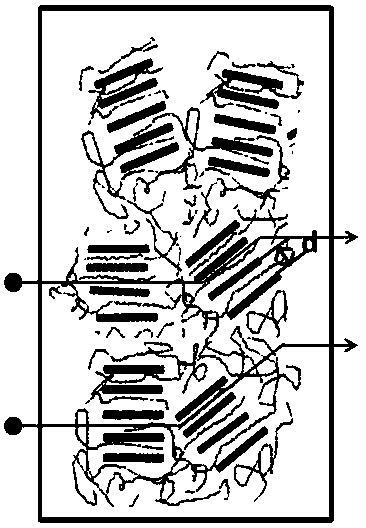

Image

Examples

Embodiment 1

[0034] Embodiment 1: adopt the method of the present invention to prepare the polyvinylamine composite membrane with lamellar screening channel, the steps are as follows:

[0035] Step 1, prepare 1mg / mL graphene oxide dispersion liquid by Hummers method;

[0036] Step 2: Select 100 mL of the above-mentioned graphene oxide dispersion liquid and disperse it ultrasonically to form a uniform and stable aqueous solution. Subsequently, 15% polyvinylamine aqueous solution was added dropwise, and the mass ratio of graphene oxide and polyvinylamine was adjusted to 1:0.5, ultrasonically dispersed for 1 h, and stirred at room temperature for 6 h to obtain a uniform mixture, which was centrifuged and dried for further processing. with , named product A. The interlayer spacing of graphene oxide regulated by polyvinylamine intercalation in product A is 8.9 Å;

[0037]Step 3: Dissolve 0.5g of polyvinylamine and 0.00375g of product A in 9.5g of aqueous solution, and ultrasonically disperse ...

Embodiment 2

[0040] Embodiment 2: adopt the method of the present invention to prepare the polyvinylamine composite membrane with lamellar screening channel, the steps are as follows:

[0041] Step 1, prepare 2 mg / mL graphene oxide dispersion by Hummers method;

[0042] Step 2: Select 50 mL of the above-mentioned graphene oxide dispersion and disperse it ultrasonically to form a uniform and stable aqueous solution. Subsequently, 15% polyvinylamine aqueous solution was added dropwise, the mass ratio of graphene oxide and polyvinylamine was adjusted to be 1:1, ultrasonically dispersed for 3 h, and stirred at room temperature for 8 h to obtain a uniform mixture, which was centrifuged and dried for further processing. with , named product A. The interlayer spacing of graphene oxide regulated by polyvinylamine intercalation in product A is 11.2 Å;

[0043] Step 3: Dissolve 0.5g of polyvinylamine and 0.005g of product A in 9.5g of aqueous solution, and ultrasonically disperse until the solutio...

Embodiment 3

[0046] Embodiment 3: adopt the method of the present invention to prepare the polyvinylamine composite membrane with lamellar screening channel, the steps are as follows:

[0047] Step 1, prepare 2 mg / mL graphene oxide dispersion by Hummers method;

[0048] Step 2: Select 50 mL of the above-mentioned graphene oxide dispersion and disperse it ultrasonically to form a uniform and stable aqueous solution. Subsequently, 15% polyvinylamine aqueous solution was added dropwise, the mass ratio of graphene oxide and polyvinylamine was adjusted to be 1:2, ultrasonically dispersed for 6 h, and stirred at room temperature for 12 h to obtain a uniform mixed solution, which was centrifuged and dried for further processing. with , named product A. The interlayer spacing of graphene oxide regulated by polyvinylamine intercalation in product A is 15.4 Å;

[0049] Step 3: Dissolve 0.5g of polyvinylamine and 0.0075g of product A in 9.5g of aqueous solution, and ultrasonically disperse until th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com