Manufacturing method of novel haze-prevention mask

A production method and mask technology, applied in protective clothing, clothing, clothing and other directions, can solve the problems of poor adsorption of anti-fog masks and the inability to identify and control the adsorption function of activated carbon, and achieve excellent fit effect and airtightness. Better filtering effect and increased breathing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

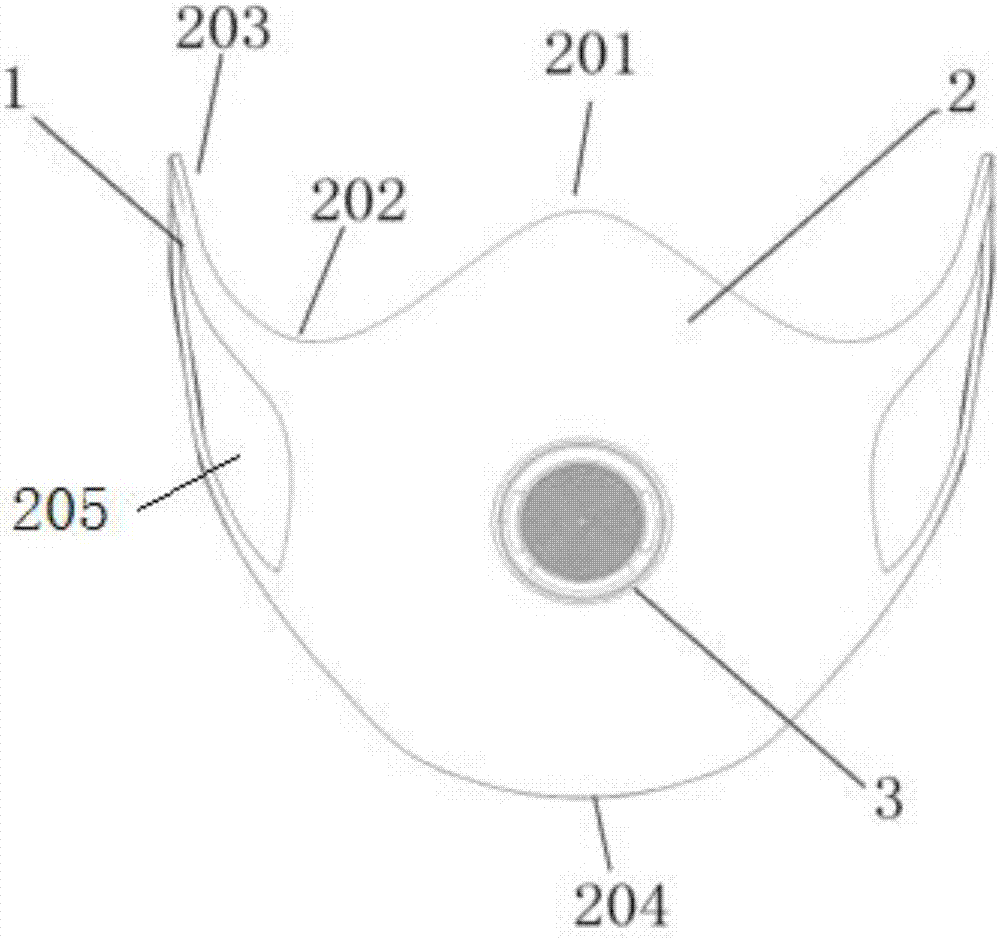

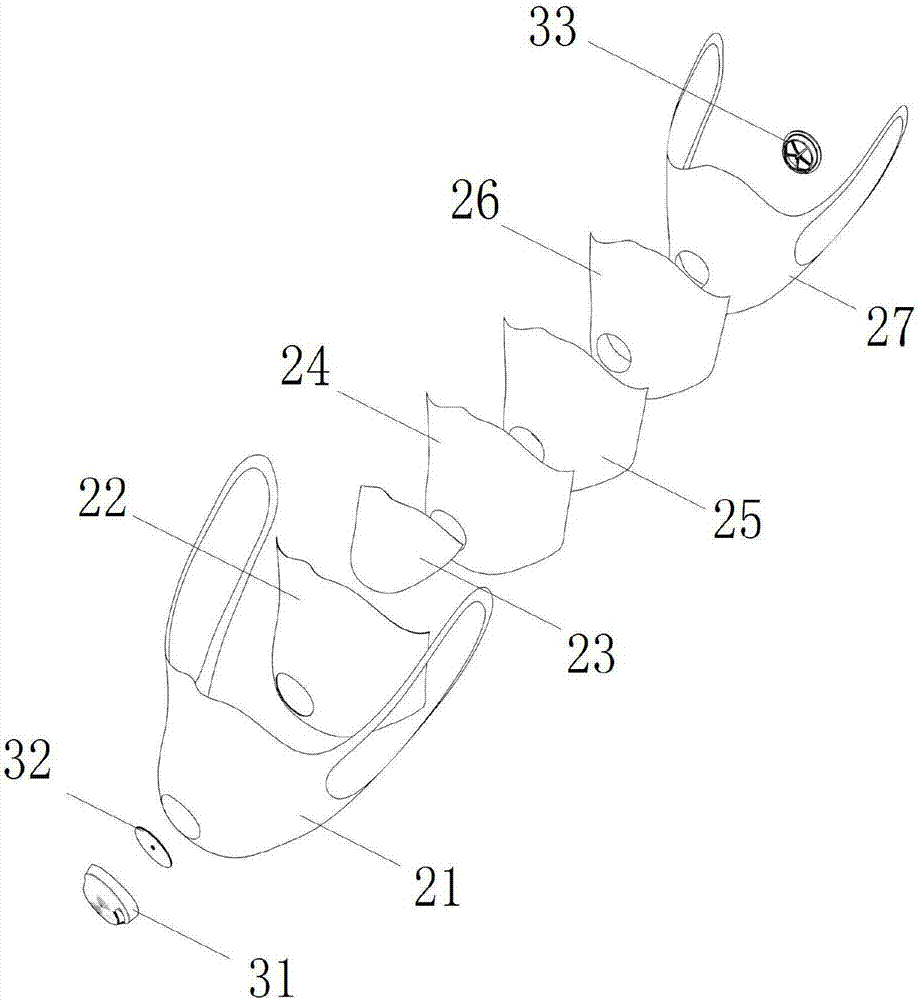

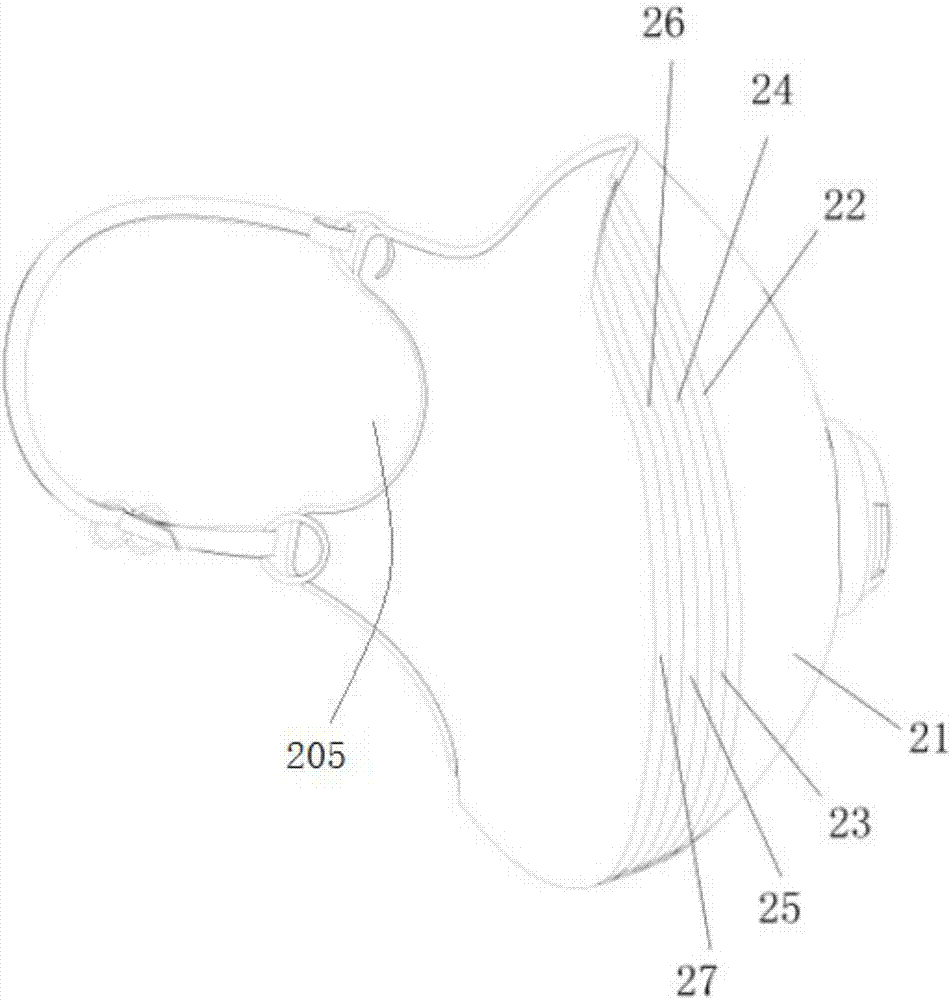

[0032] Such as Figure 1 to Figure 3 Shown, a kind of manufacturing method of novel mouth mask, mouth mask comprises mask 2, ear band 1, breather valve 3, face mask 2 front middle is provided with breather valve installation hole, breather valve 3 is connected with breather valve installation hole, earband is provided with Two, one on the left and one on the left, the ear straps are respectively connected to the horizontal sides of the mask. The two sides are respectively provided with a groove 202 at the transition position between the back of the nose and the cheeks on both sides, and the outside of the groove 22 is provided with a smaller protrusion 203 matching the cheek and the cheekbone. The lower protrusion 204 of bone anastomosis, the face mask 2 includes a connected cotton ble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com