Self-crosslinking epoxy/polyacrylate composite soap-free emulsion and preparation technology thereof

A polyacrylate, soap-free emulsion technology, applied in the direction of coating, can solve the problems of unsatisfactory adhesion, limited application range, poor stain resistance, etc., to improve physical properties and chemical resistance, good physical-chemical properties , good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

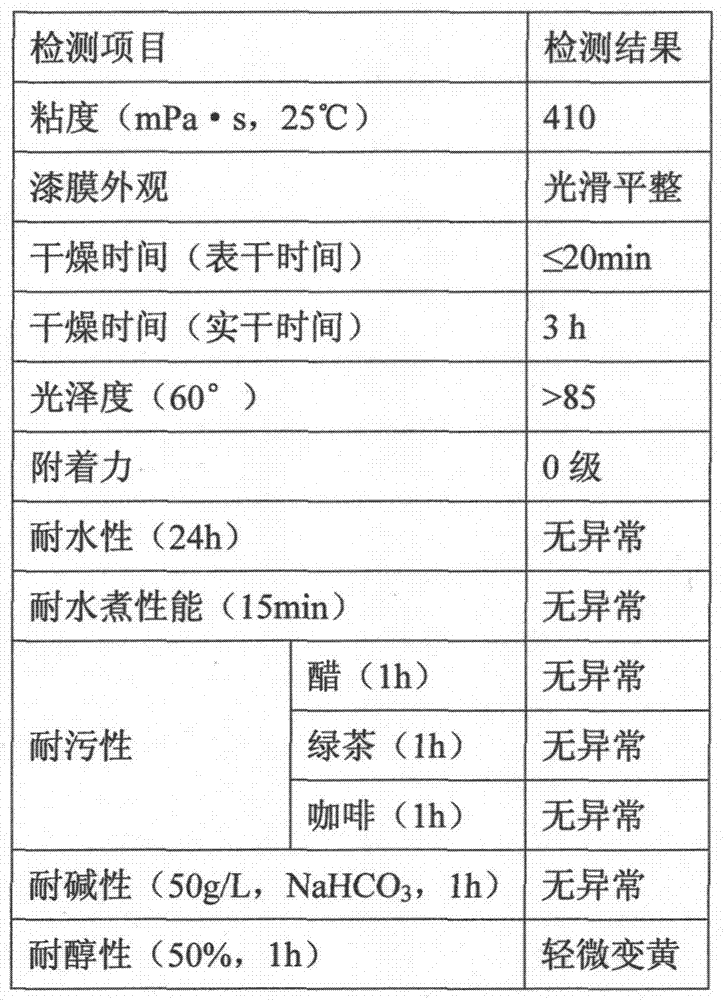

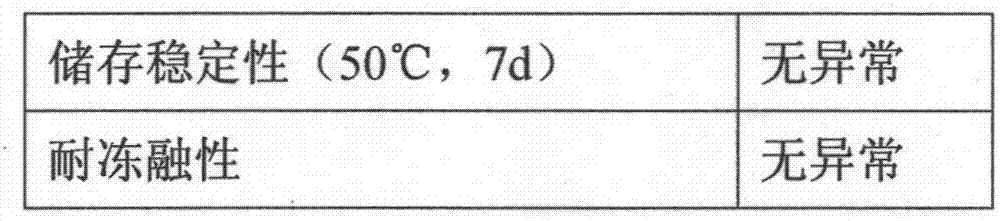

Examples

Embodiment 1

[0038] A preparation process of cross-linked epoxy / polyacrylate composite soap-free emulsion:

[0039] (1) Preparation of core and shell pre-emulsion

[0040] Add 0.2 parts of emulsifier V-20S, 0.1 parts of emulsifier AE200 and 10 parts of deionized water into the reaction kettle, stir evenly, heat up to 50°C, slowly add 3 parts of E51 epoxy resin, 12 parts of methyl The nuclear monomer of methyl acrylate and 7 parts of butyl acrylate was dropped within 60 minutes, and pre-emulsified for 30 minutes to obtain a nuclear pre-emulsion.

[0041] Add 0.3 parts of emulsifier V-20S, 0.15 parts of AE200 and 15 parts of deionized water into the reaction kettle, stir evenly, raise the temperature to 50°C, and start to add 5 parts of DAAM, 9 parts of methyl methacrylate, 13 Parts of butyl methacrylate, 3 parts of methacrylic acid shell monomer, drop in 60 minutes, and pre-emulsify for 30 minutes to obtain shell pre-emulsion.

[0042] (2) Preparation of core-shell emulsion

[0043]Get 1...

Embodiment 2

[0047] A preparation process of cross-linked epoxy / polyacrylate composite soap-free emulsion:

[0048] (1) Preparation of core and shell pre-emulsion

[0049] Add 0.3 parts of emulsifier V-20S and 10 parts of deionized water into the reaction kettle, stir evenly, raise the temperature to 50°C, slowly add 5 parts of E44 epoxy resin, 12 parts of methyl methacrylate, and 7 parts of acrylic acid The nuclear monomer of butyl ester was dropped within 60 minutes, and pre-emulsified for 30 minutes to obtain the nuclear pre-emulsion.

[0050] Add 0.5 parts of emulsifier V-20S and 15 parts of deionized water into the reaction kettle, stir evenly, raise the temperature to 50°C, and start adding 3 parts of DAAM, 10 parts of methyl methacrylate, and 12 parts of butyl methacrylate dropwise. ester, 2 parts of methacrylic acid shell monomer, dripped in 60 minutes, and pre-emulsified for 30 minutes to obtain a shell pre-emulsion.

[0051] (2) Preparation of core-shell emulsion

[0052] Take...

Embodiment 3

[0056] A preparation process of cross-linked epoxy / polyacrylate composite soap-free emulsion:

[0057] (1) Preparation of core and shell pre-emulsion

[0058] Add 0.3 parts of emulsifier M-20S and 10 parts of deionized water into the reaction kettle, stir evenly, raise the temperature to 50°C, slowly add 5 parts of E51 epoxy resin, 11 parts of methyl methacrylate, and 5 parts of acrylic acid The nuclear monomer of butyl ester was dropped within 60 minutes, and pre-emulsified for 30 minutes to obtain the nuclear pre-emulsion.

[0059] Add 0.5 parts of emulsifier M-20S and 15 parts of deionized water into the reaction kettle, stir evenly, raise the temperature to 50°C, and start adding 4 parts of DAAM, 9 parts of methyl methacrylate, and 12 parts of butyl methacrylate dropwise. ester, 3 parts of methacrylic acid shell monomer, dripped in 60 minutes, and pre-emulsified for 30 minutes to obtain a shell pre-emulsion.

[0060] (2) Preparation of core-shell emulsion

[0061] Take ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com