Drug particle loaded degradable catheter

A catheter and drug technology, applied in the field of degradable catheter method, can solve the problems of long degradation and absorption time, slow degradation speed, weak cell adhesion, etc., and achieve the effect of good hydrophilicity, low production and operation costs, and short degradation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1. Preparation of β-chitosan / polylactic acid composite material

[0032] A) Preparation of polylactic acid: It includes two steps S1 to S2:

[0033] S2. Preparation of lactide: using 85wt% of D,L-lactic acid as raw material, anhydrous zinc oxide as catalyst, heating to 110°C, vacuum distillation, then rapid heating to 220°C, vacuum distillation, The distilled fraction is washed with ethyl acetate and recrystallized to obtain D,L-lactide;

[0034] S2. Synthesis of polylactic acid: Weigh the D,L-lactide prepared in the above steps and place it in a clean ampere flask, and inject 0.2% by mass of D,L-lactide into a chloroform solution of stannous octoate as a trigger Evacuated, the bottle mouth is fused and sealed, placed in an oil bath at a temperature of 150°C, and polymerized for 25 hours to obtain polylactic acid with a number average molecular weight of 65,000;

[0035] B) Preparation of composite material: Take the polylactic acid prepared above, dissolve it in an o...

Embodiment 2

[0042] Example 2. Degradable catheter of the present invention

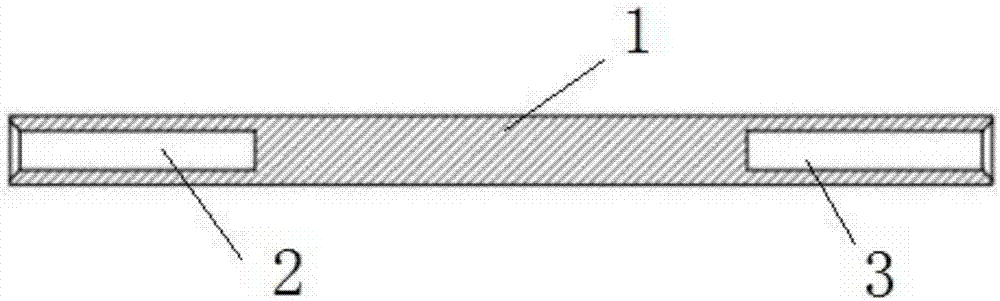

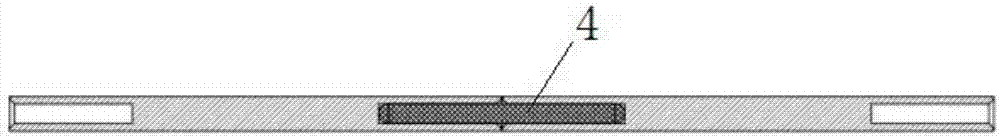

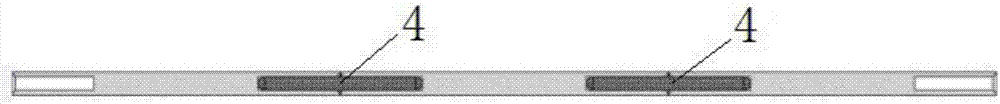

[0043] Embodiment 1 of the present invention provides a degradable catheter for loading drug particles, which includes a connecting portion 1, a first lumen 2 and a second lumen 3 provided at both ends of the connecting portion for containing drug particles 4. The connecting portion is used to connect the first lumen 301 and the second lumen 302. The connecting portion only serves as a connection. It can be of any shape, as long as it can achieve the purpose of connecting the first lumen and the second lumen. Within the scope of the connecting portion of the present invention, preferably, the connecting portion is preferably cylindrical. Preferably, the diameter of the connecting portion is 0.8-1.8 mm, and more preferably, the diameter of the connecting portion is 1.2 mm. The length of the connecting portion is preferably 10-40 mm, more preferably 25 mm. The first lumen and the second lumen are preferably cylindri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com