Synchronous filling equipment for different bodies

A filling equipment and allogeneic technology, which is applied in the field of allogeneic synchronous filling equipment, can solve the problems of slow filling speed and foam filling of water products, and achieve the effect of ensuring consistent intervals and facilitating simplicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

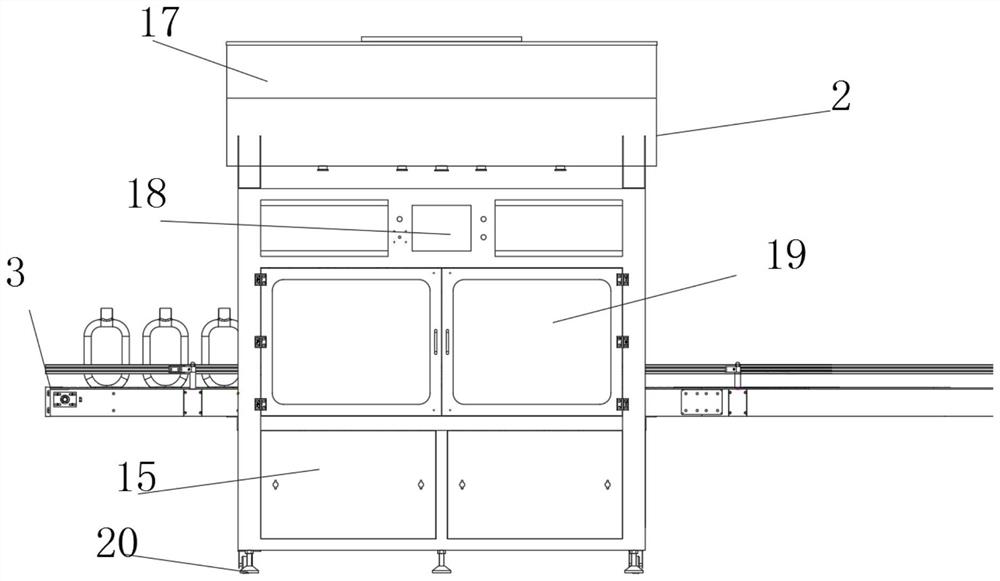

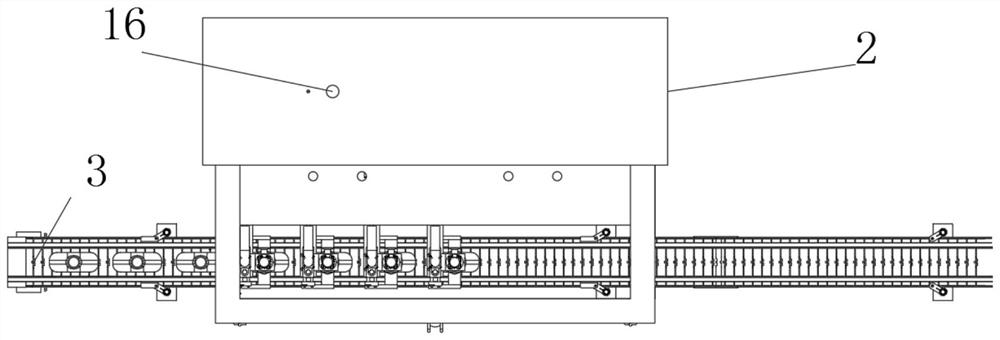

[0022] see figure 1 , 2 , 3, a different body synchronous filling equipment, including a filling mechanism 1, a casing 2 and a conveying mechanism 3, the conveying mechanism 3 runs through the inside of the casing 2, and the right side of the conveying mechanism 3 is fixed with three chucks 21 and 21 by bolts The front and back are evenly distributed, the upper part of the shell 2 is provided with a storage room 17, the storage room 17 is connected to the filling head 13 through a pipeline, the top of the storage room 17 is provided with a feeding port 16, and the middle of the front of the shell 2 is provided with a display screen 18 , the display screen 18 is a touch screen display screen, the display screen 18 below is provided with two cabinet doors 19, the cabinet doors 19 are evenly distributed on the left and right sides, the cabinet door 19 is fixed on the front of the shell 2 by hinges, and the cabinet door 19 is provided with two electrical appliances. Cabinet 15, e...

Embodiment 2

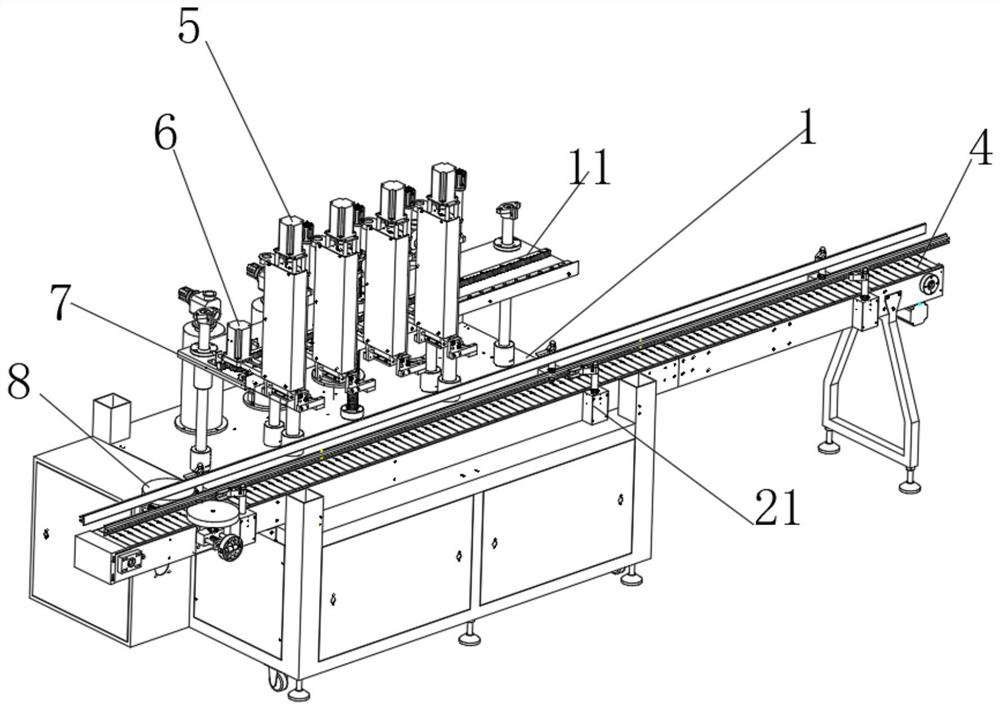

[0025] see figure 1 , 2 , 3, 4, a different body synchronous filling equipment, including a filling mechanism 1, the filling mechanism 1 mainly includes a conveyor chain 4, and the front end of the conveyor chain 4 is fixed with two bottle dividers 8 by bolts, and the bottle dividers 8 are evenly spaced distribution, four piston cylinder valve bodies 9 are fixed by bolts on the left side of the conveyor chain 4, the piston cylinder valve bodies 9 are evenly distributed front and rear, the top of the piston cylinder valve body 9 is fixed with a fixed plate 11 by bolts, and the left end of the fixed plate 11 is fixed by bolts with a Five filling height tooth bars 14, the filling height tooth bars 14 are evenly distributed front and back, the right side of the filling height tooth bar 14 is fixed with a rack 10 by bolts, the right side of the rack 10 is provided with a linear slide rail 12, and the rack The front end of 10 is connected with four tracking filling servos 6 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com