Accurate hill-seeding furrow opener for seeding machine

A seeder and opener technology, which is applied to the parts of the seeder, the machinery of interval-type quantitative seeding, and the excavation/covering of trenches, etc., can solve the problems of uneven seed distribution, reduced crop yield, etc., and reduce seed damage. efficiency, fast seeding speed, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

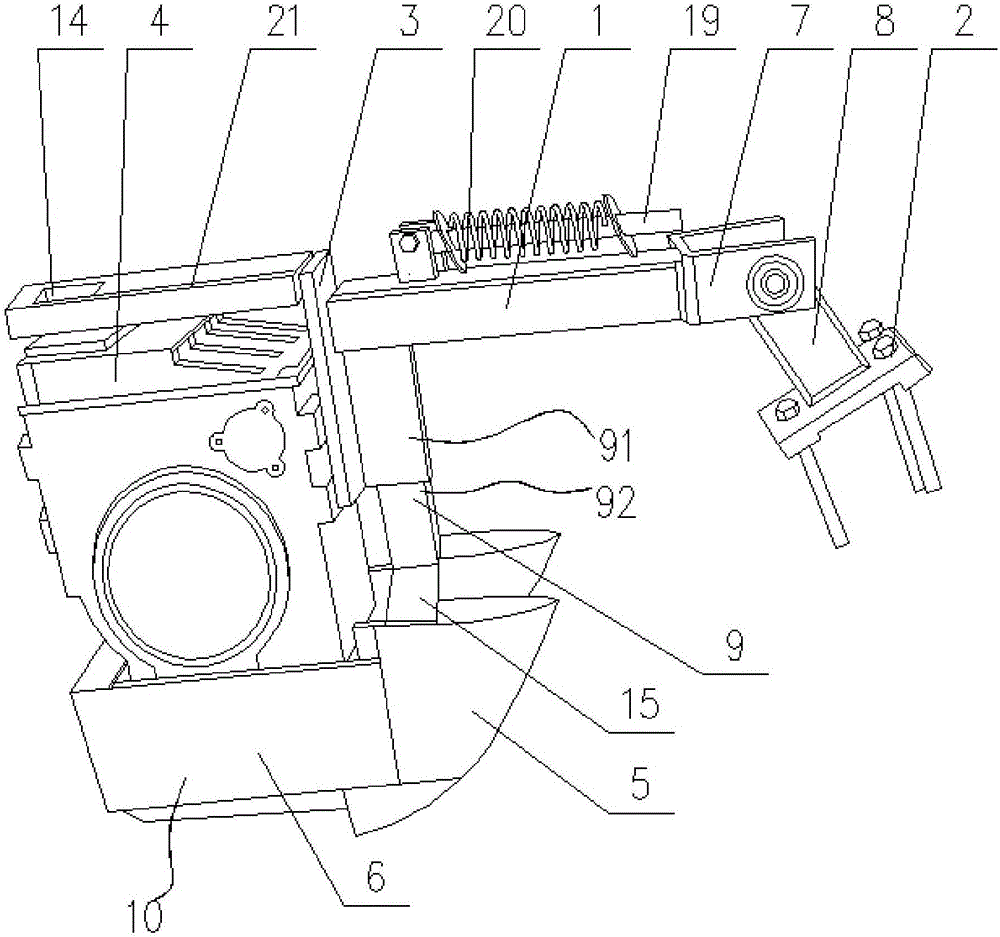

[0023] Specific implementation mode one: combine Figure 1-Figure 5 Describe this embodiment, the planter precision on-demand sowing opener of this embodiment includes support body 1, flange mounting part 2, seeder mounting plate 3, seeder 4, ditching device 5 and sowing guide device 6, described The bracket body 1 is a square tube bracket, the front end of the bracket body 1 is equipped with a U-shaped block 7, and a connecting rod 8 is hinged in the U-shaped groove of the U-shaped block 7, and the flange mounting part 2 is welded on the connecting rod 8, the rear end of the support body 1 is welded with a seeder mounting plate 3 and a ditching bracket 9, the seeder 4 is installed on the seeder mounting plate 3 by bolts, and the ditching device 5 It is welded and connected with the sowing guide 6 front and back and is connected with the ditching support 9. So set, the sower model of the present invention is: Hailunwang 2BJG-4 (Heilongjiang Hailunwang Agricultural Machinery M...

specific Embodiment approach 2

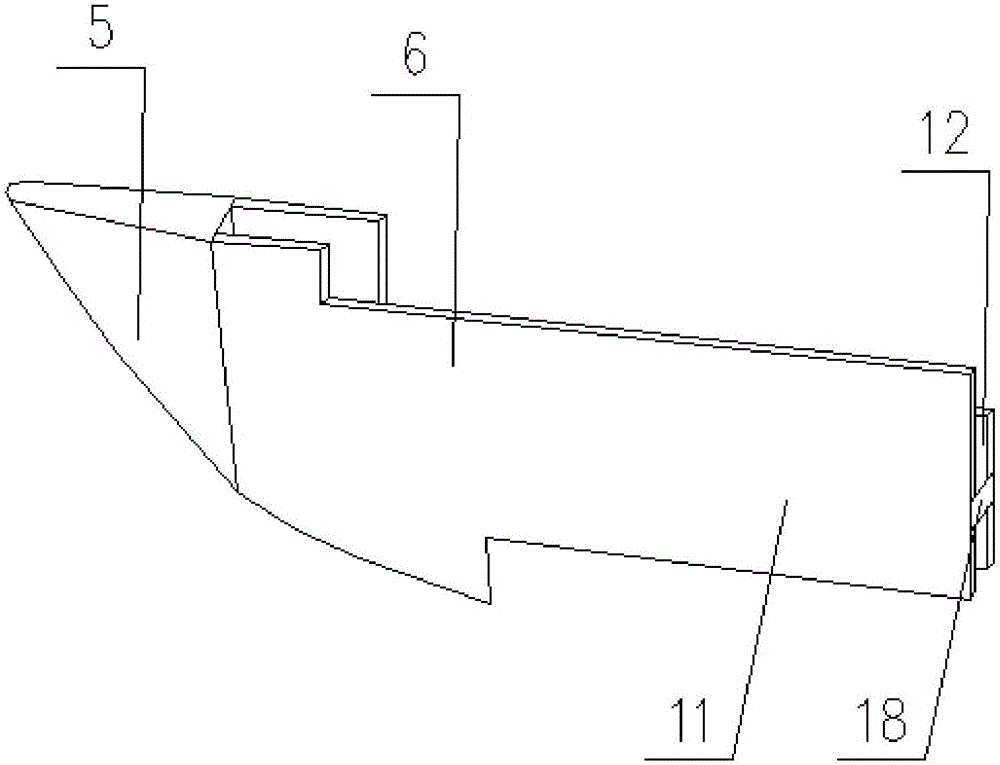

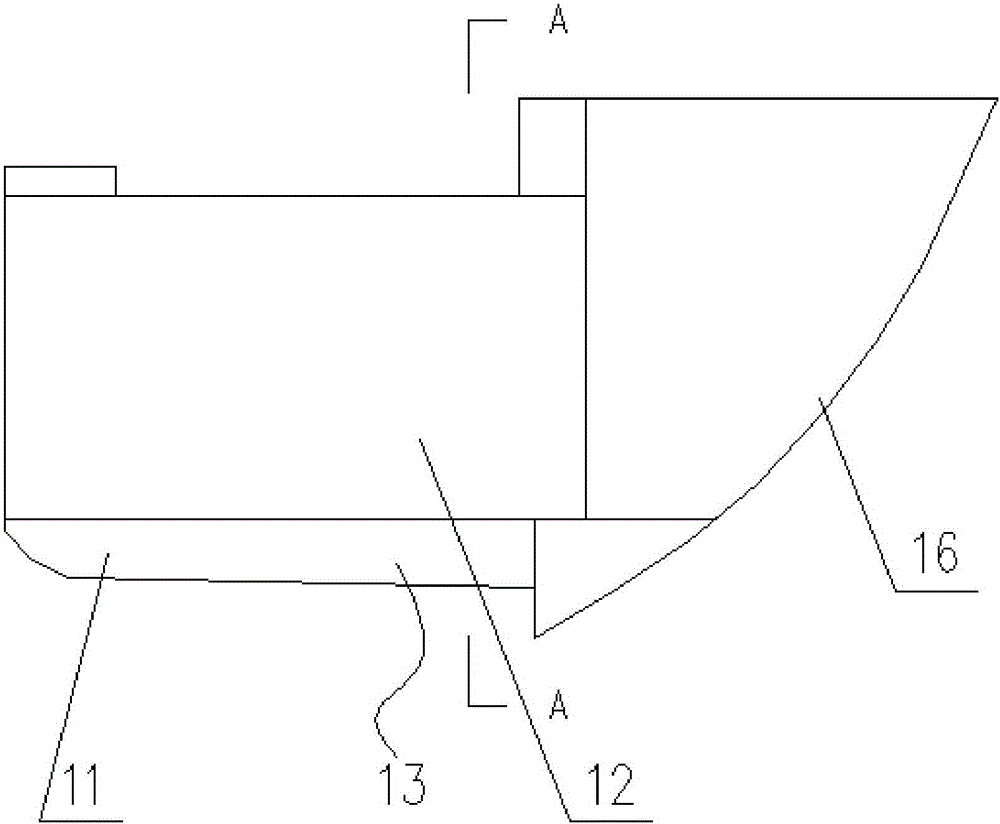

[0024] Specific implementation mode two: combination figure 2 , image 3 Illustrate this embodiment, the sowing guide device 6 described in the planter precision on-demand sowing opener of this embodiment includes two parallel seed guide frames 10, and the described seed guide frame includes a guide plate 11 and a fixed plate 12, The guide plate 11 and the fixed plate 12 are welded and installed in parallel. The welded guide plate 11 and the fixed plate 12 form a seeding passage 17, and the bottom of the guide plate 11 and the fixed plate 12 form a height difference; The guide part 13 is arranged obliquely toward the direction of the fixing plate 12 . In this way, after the seeds are discharged in the seeder 4, they are discharged into the seeding channel 17 formed by the guide plate 11 and the fixed plate 12. Part 13 slides into the ditch, which avoids the defect that the seeds cannot normally fall into the ditch hole due to factors such as throwing or scraping after the s...

specific Embodiment approach 3

[0025] Specific implementation mode three: combination image 3 Describe this embodiment, the back end of the guide plate 11 and the fixed plate 12 described in the precision on-demand sowing opener of the planter in this embodiment is welded with a soil cover baffle 18 . Set in this way, after the seeder sows, the soil cover baffle 18 that is arranged on the rear end of the guide plate 11 and the fixed plate 12 can scrape the soil after ditching into the seed planting groove, so that the soil cover depth of the seeds is consistent, so that the seedlings grow The height is controlled, which is convenient for the later growth management of crop plants.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com