Same-speed air cavity rolling type bunch planting device

A rolling and hole-seeding technology, applied in the direction of planter parts, etc., can solve problems such as failure to absorb seeds, leakage of seeds, mutual interference of pipelines or lines, etc., to achieve stable negative pressure, reduce porosity, and improve quality and stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

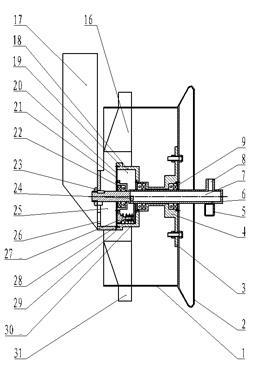

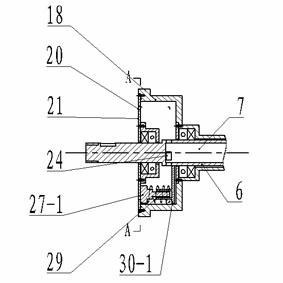

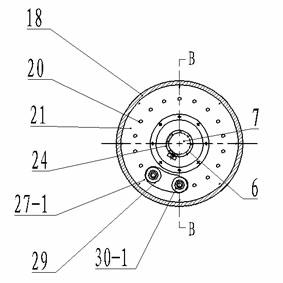

[0014] as attached figure 1 , 2 , 3, 4, the present invention mainly comprises hole sowing cylinder 1, film pressing wheel 2, negative pressure seed picker body 18, wherein the hole planting cylinder 1, film pressing wheel 2, negative pressure seed picker body 18 and cylinder main shaft 6 pass through Bearing connection, the pressure film wheel 2 is fixedly connected with the reinforcement plate 3 fixedly connected with it or directly with the negative pressure seed picker body 18 through a connecting piece, and an air-tight block fixedly connected with the drum main shaft 6 is set in the negative pressure seed picker body 18 27. The pressure film wheel 2 is fixedly connected with the negative pressure seed picker body 18 through a connecting piece through the reinforcing plate 3 fixedly connected with it, and the connecting piece is a sleeve sleeved on the main shaft of the drum, and the sleeve and the main shaft of the drum 6 clearance fit; the drum main shaft 6 is a hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com