A method of embolization

A technology for a plug and a plug portion is applied in the field of a plug forming method and a semiconductor device having the plug, which can solve the problems of great influence on the device performance, unfavorable metal layer conduction, and difficulty in uniform entry of tungsten, etc., so as to increase the read/write speed. , lower temperature, the effect of uniform and dense inside

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

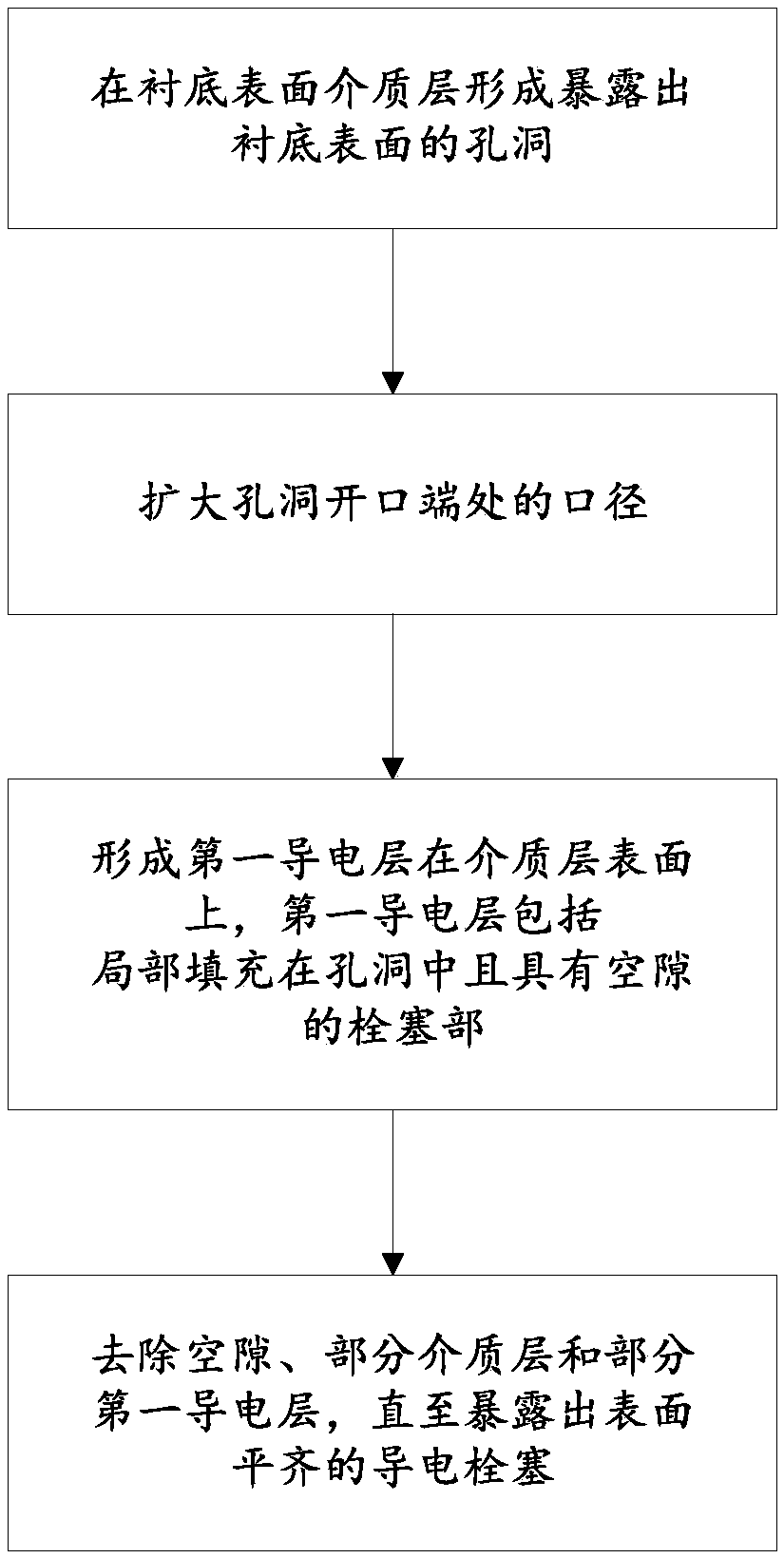

[0068] A method for forming a plug, comprising the steps of:

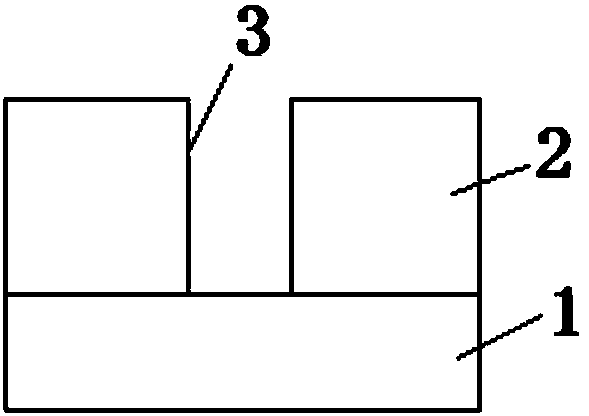

[0069] 1) a semiconductor substrate 1 is provided, a dielectric layer 2 is formed on the surface of the substrate 1 by a chemical vapor deposition process, and a hole 3 exposing the upper surface of the substrate 1 is formed on the dielectric layer 2 by an anisotropic dry etching process;

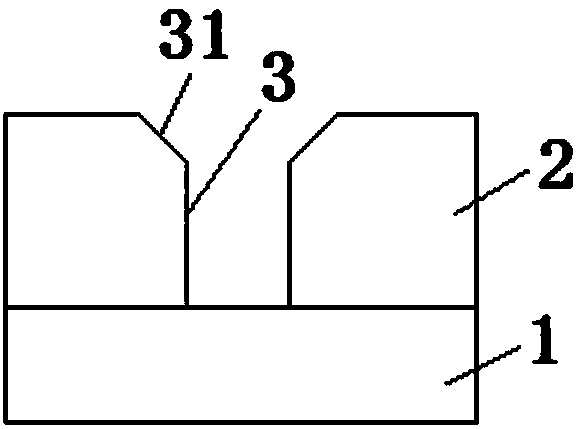

[0070] 2) using sputtering process or in-situ ashing process to expand the aperture at the opening end 31 of the hole 3, and relatively reduce the aspect ratio of the hole 3;

[0071] 3) Depositing Co, CoSi and Co into the interior of the hole 3 at the open end 31 of the hole 3 2 Combination materials of Si;

[0072] 4) An annealing process is performed after the deposition, and the composite material forms a layer of CoSi deposited on the bottom of the hole 3 through the reaction. 2 the second conductive layer 7;

[0073] 5) after forming the second conductive layer 7, a wet cleaning process is performed to remove the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com