A visual intelligent detection mechanism for optical film

A detection mechanism and optical film technology, applied in the direction of optical testing flaws/defects, material analysis through optical means, measuring devices, etc., can solve problems such as structural redundancy, unstable product quality, and complex testing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

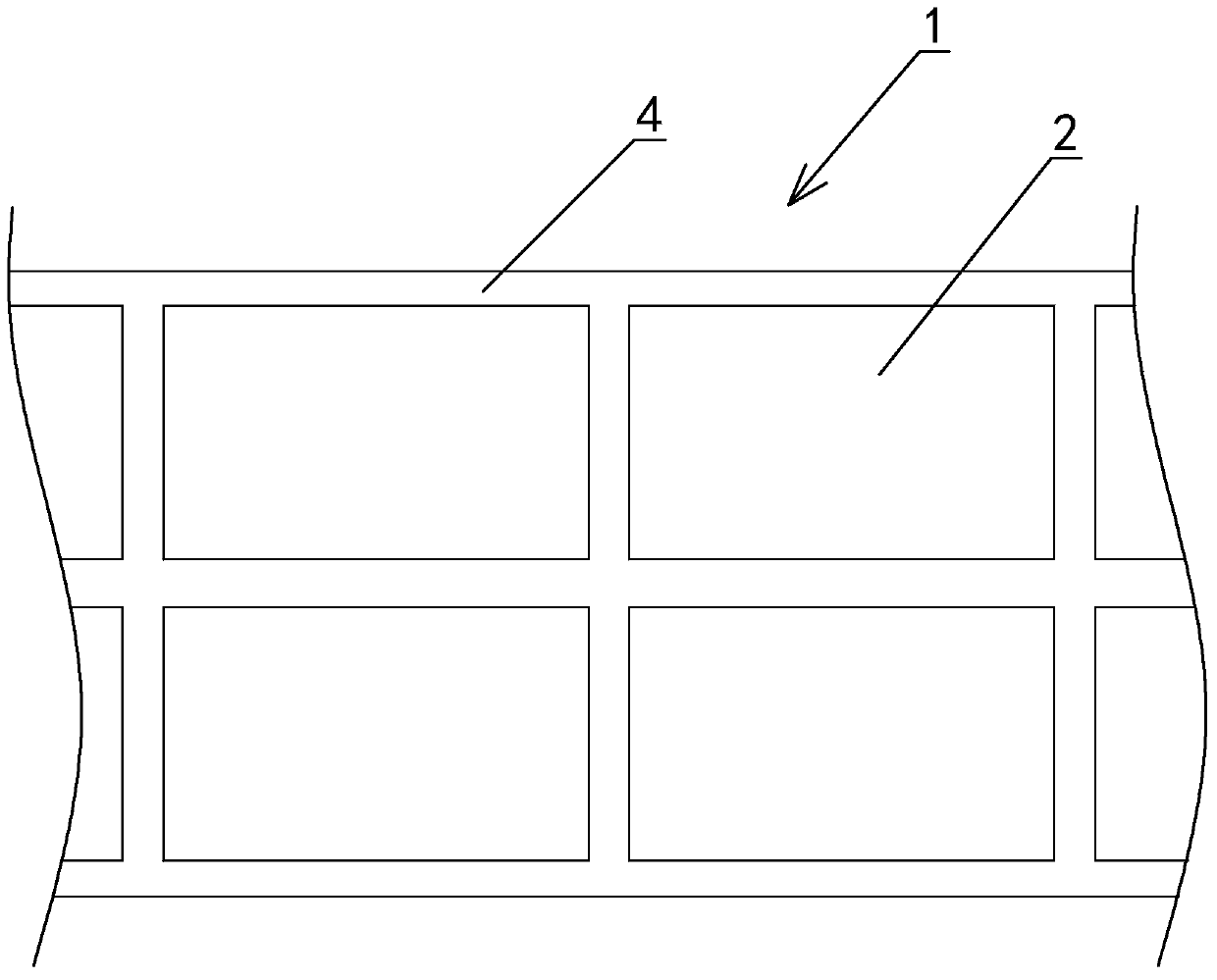

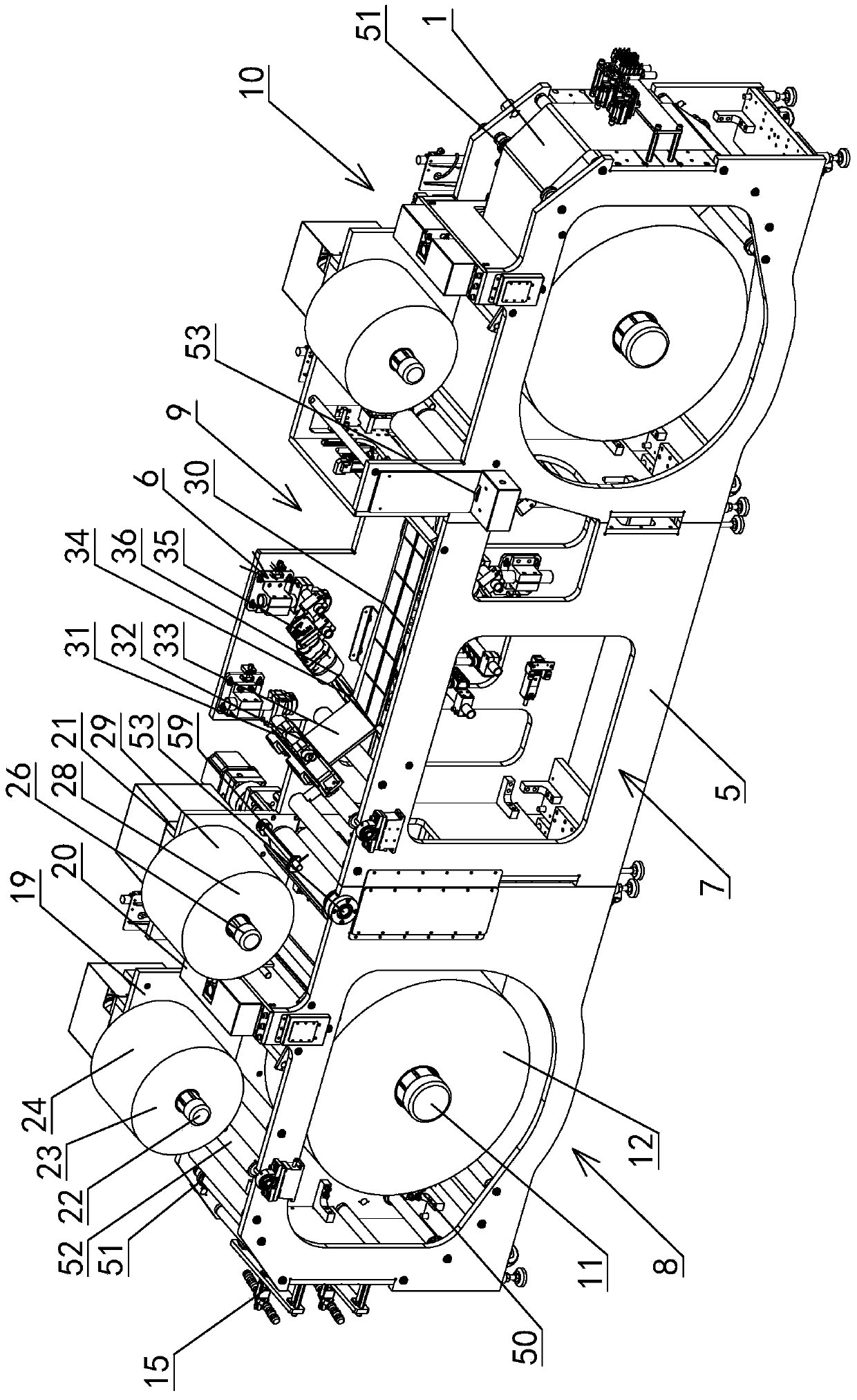

[0073] Example: see attached Figure 1-12 As shown, a visual intelligent detection mechanism for an optical film is used to detect an optical film product 2 in an optical film material belt 1. The optical film material belt 1 consists of a protective film 3, an optical film product 2 and a base film 4 from above. to the following combination (such as figure 1 , 2 ).

[0074] Described detection equipment comprises a frame 5, and the length direction of this frame 5 is the X-axis direction, and the width direction of frame 5 is the Y-axis direction; Displaced backward, the frame 5 is divided into an upper space 6 and a lower space 7 in the Z-axis direction based on the optical film strip 1;

[0075] The detection equipment also includes a feeding unit 8, a detection unit 9 and a receiving unit 10 arranged in the frame 5 from front to back along the X-axis direction; wherein,

[0076] Such as Figure 6~8 As shown, the feeding unit 8 includes:

[0077] A feeding module, loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com