Surface polishing treatment method for aluminum products

A technology of surface polishing and treatment method, applied in the field of aluminum product processing, to achieve the effect of optimizing the content of added components, slowing down corrosion and controlling pitting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

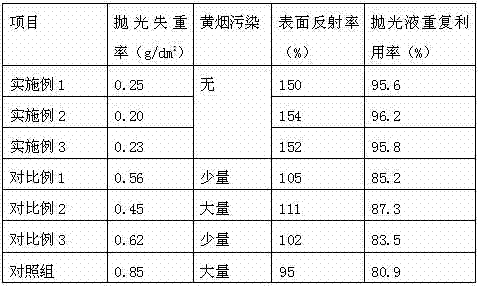

Examples

Embodiment 1

[0017] A surface polishing treatment method in aluminum product processing, comprising the following steps:

[0018] (1) Prepare acidic chemical polishing base liquid: mix sulfuric acid solution and phosphoric acid solution according to the volume ratio of 2.0:0.8, the molar concentration of sulfuric acid solution is 1.5 mol / liter, and the molar concentration of phosphoric acid solution is 1.2 mol / liter. Aluminum nitrate was added to the liquid to make the concentration of aluminum ions in the base liquid 0.10 mol / liter;

[0019] (2) Add a surfactant with a mass fraction of 0.1% to the base liquid in step (1), stir for 20 minutes under heating in a water bath at a temperature of 40°C, and then add a mass fraction of 3% to the mixing system The absorption conversion agent contains urea, sulfamic acid, triethanolamine, magnesium oxide, zinc oxide, calcium oxide, and liquid paraffin. Stir it evenly, place it on an electric heating plate and heat it, and when the temperature rises...

Embodiment 2

[0026] A surface polishing treatment method in aluminum product processing, comprising the following steps:

[0027] (1) Prepare acidic chemical polishing base liquid: mix sulfuric acid solution and phosphoric acid solution according to the volume ratio of 2.2:0.9, the molar concentration of sulfuric acid solution is 1.8 mol / liter, and the molar concentration of phosphoric acid solution is 1.3 mol / liter. Add aluminum nitrate in the liquid, so that the concentration of aluminum ions in the base liquid is 0.11 mol / liter;

[0028] (2) Add a surfactant with a mass fraction of 0.15% to the base liquid in step (1), stir for 25 minutes under heating in a water bath at a temperature of 45°C, and then add a mass fraction of 4% to the mixing system The absorption transformation agent contains urea, sulfamic acid, triethanolamine, magnesium oxide, zinc oxide, calcium oxide, liquid paraffin, stirs evenly, puts it on the electric hot plate to heat, when the temperature rises to 140 ℃, name...

Embodiment 3

[0035] A surface polishing treatment method in aluminum product processing, comprising the following steps:

[0036] (1) Prepare acidic chemical polishing base liquid: mix sulfuric acid solution and phosphoric acid solution according to the volume ratio of 2.5:1, the molar concentration of sulfuric acid solution is 2.0 mol / liter, and the molar concentration of phosphoric acid solution is 1.2-1.5 mol / liter. Aluminum nitrate is added to the polishing base liquid so that the concentration of aluminum ions in the base liquid is 0.12 mol / liter;

[0037] (2) Add a surfactant with a mass fraction of 0.1-0.2% to the base liquid in step (1), stir for 30 minutes under heating in a water bath at a temperature of 50°C, and then add a mass fraction of 5% absorption transformation agent, the absorption transformation agent contains urea, sulfamic acid, triethanolamine, magnesium oxide, zinc oxide, calcium oxide, liquid paraffin, stir evenly, place on an electric heating plate to heat, when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com