Sheet stock sorting mechanism

A material sorting and rotating motor technology, which is applied in the field of material storage mechanical equipment and sheet material stacking in the production process, and can solve the problem of narrow application range, difficult limit baffles, and difficult stacking of sheet materials of various sizes, etc. problem, to achieve the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

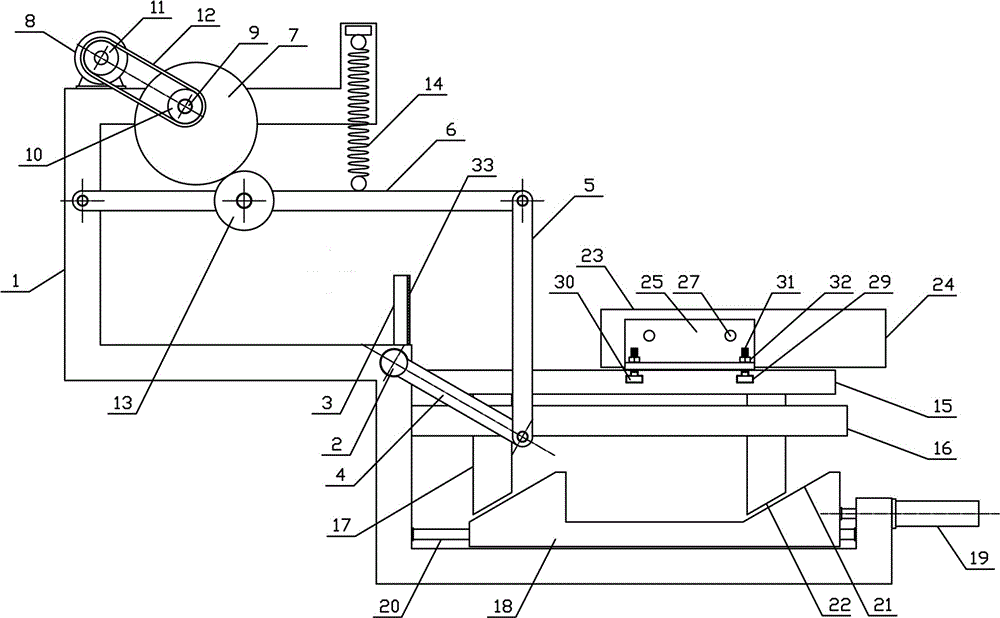

[0012] In order to further describe the present invention, the specific implementation of a slice material mechanism will be further described below in conjunction with the accompanying drawings. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

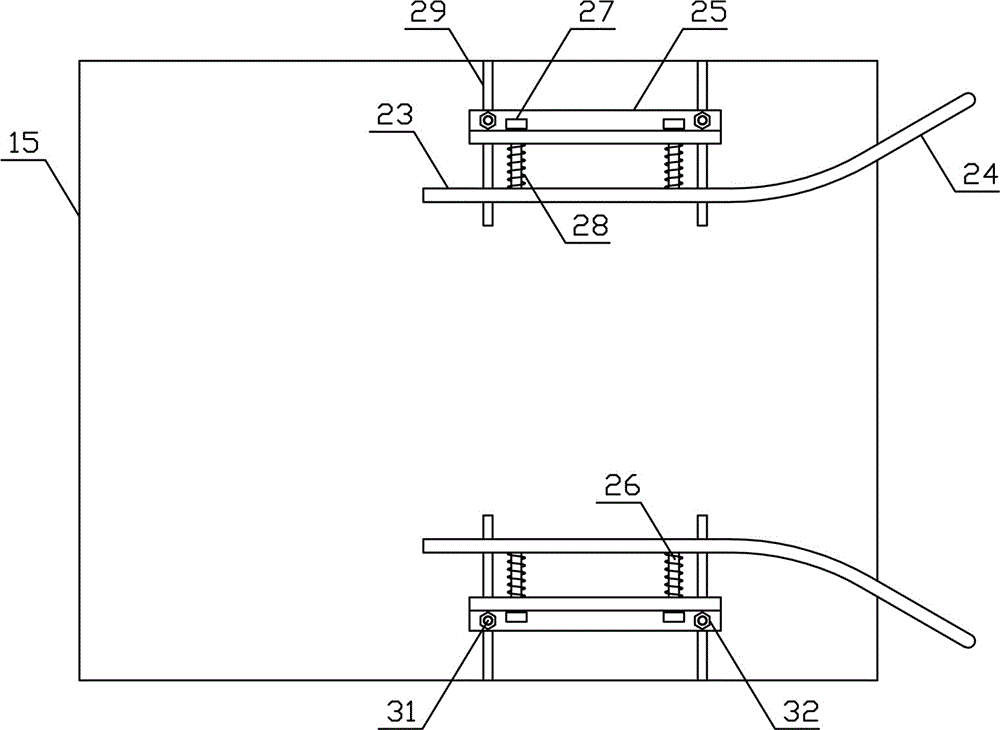

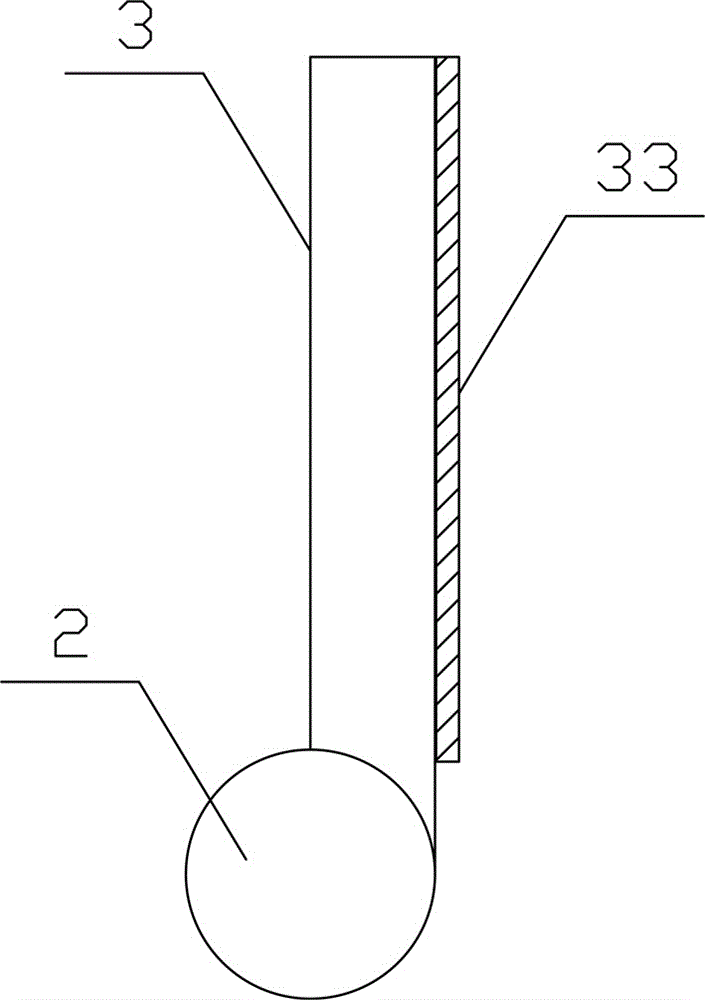

[0013] Such as figure 1 As shown, a slice feeding mechanism of the present invention includes a fixed bracket 1, a material handling mechanism and a material receiving mechanism, the material receiving mechanism is horizontally arranged on the lower side of the fixed bracket 1, and the material handling mechanism is horizontally arranged on the upper side of the fixed bracket 1. The inventive material arrangement mechanism comprises a material arrangement shaft 2, a material arrangement plate 3, a rotating plate 4, a material arrangement connecting rod 5, a reciprocating swing lever 6, a material arrangement eccentric wheel 7 and a rotating motor 8, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com