Shielding device for microwave plasma torch

A microwave plasma and shielding device technology, applied in the direction of plasma, electrical components, etc., can solve the problems of destroying the axis symmetry and stability of the plasma, melting and destroying the quartz cover, and reducing the service life, so as to improve the excitation efficiency and pinch Enhancement of action and prevention of burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

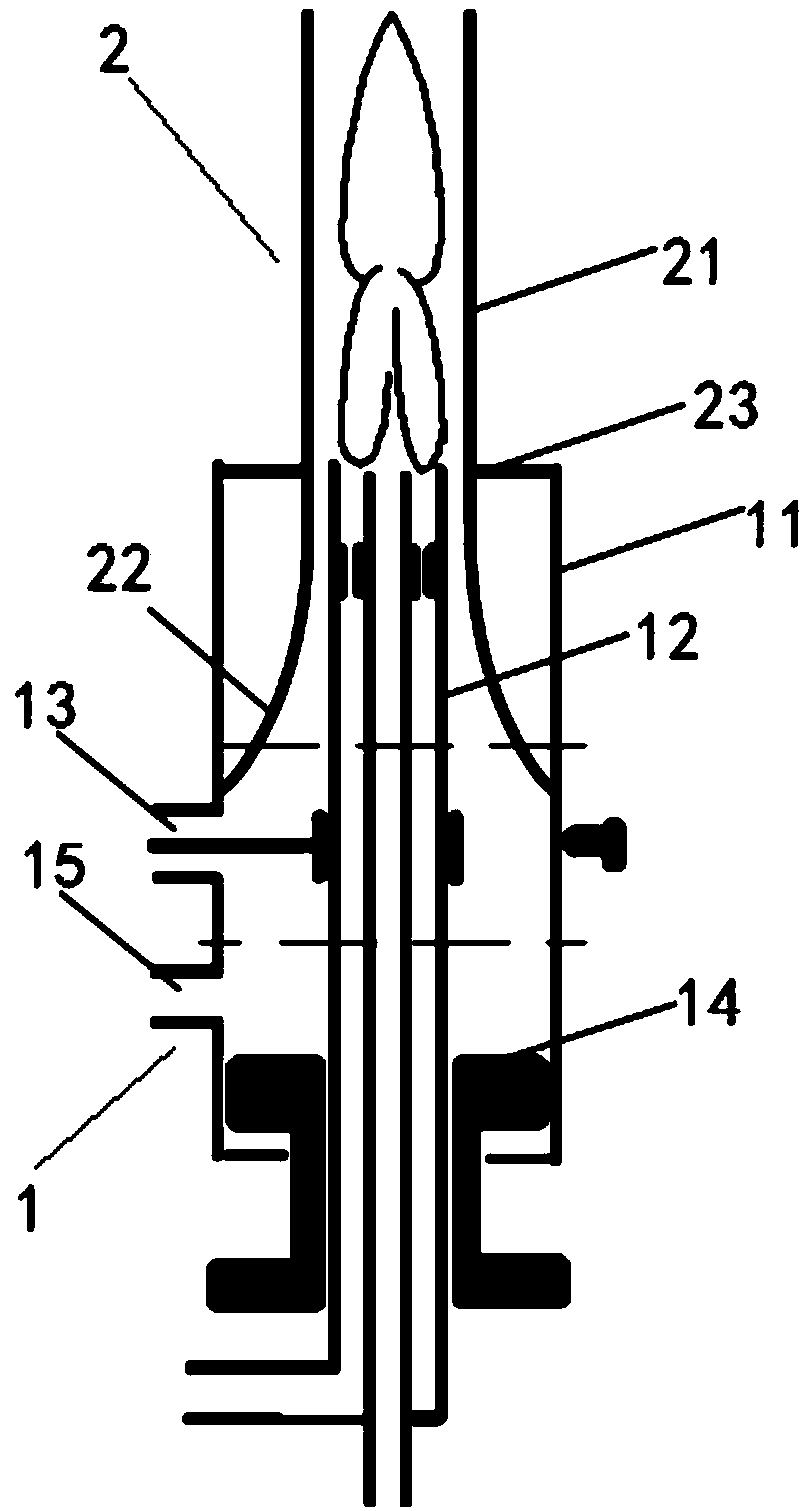

[0031] This example provides a shielding device for a microwave plasma torch, including a torch 1 for forming plasma and a shield 2 for shielding ambient gas. The structural diagrams of the torch 1 and the shield 2 are shown in figure 1 shown.

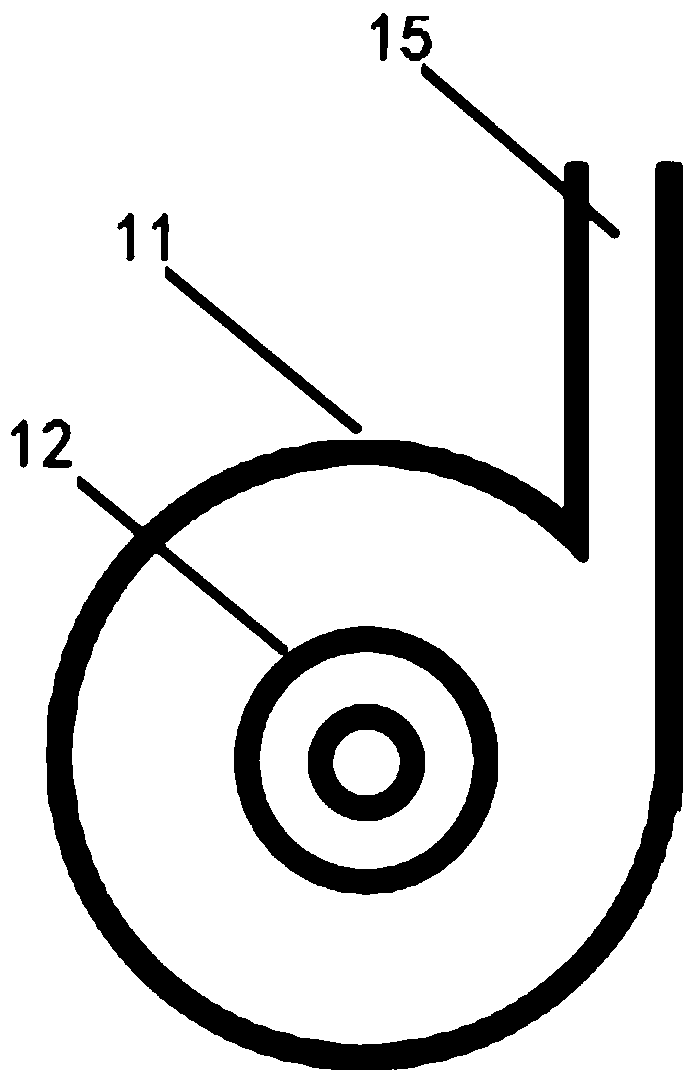

[0032] Wherein, the torch 1 includes an outer tube 11 and a middle tube 12, and the outer tube 11 is provided with a coupling antenna part 13, and the distance between the coupling antenna part 13 and the reflection end 14 is 1 / 4λ, where λ is the microwave wavelength.

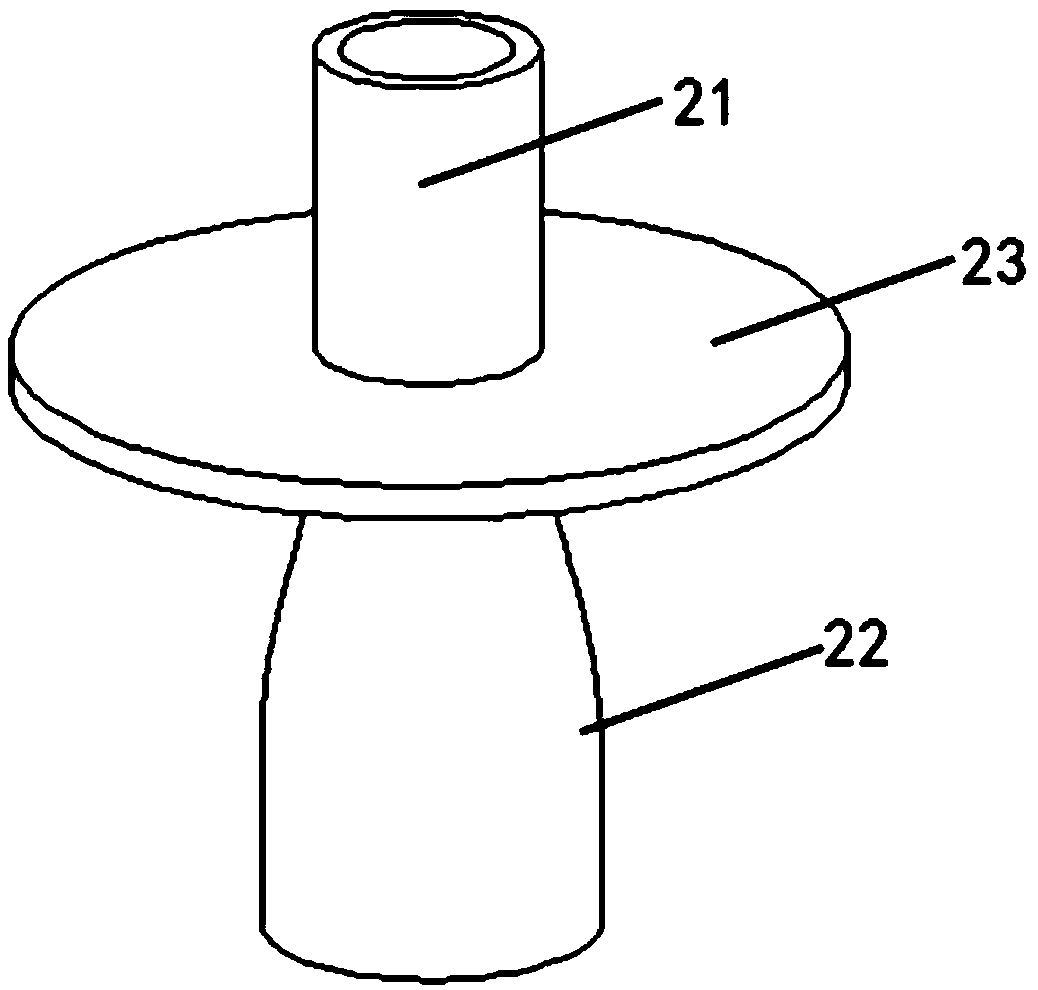

[0033] The shielding cover 2 includes a shielding tube 21, a gradient tube 22 and a sealing plate 23, and its structure is as follows: figure 2 As shown, the shielding tube 21 is a hollow straight tube, the gradient tube 22 is tapered from the bottom to the top, and the opening inner diameter of the upper end of the transition tube 22 is equal to the inner diameter of the shielding tube 21, and the upper end of the transition tube 22 is connected to the lower end of th...

Embodiment 2

[0047] Based on Embodiment 1, the structural diagram of the shielding device provided in this example is as follows Figure 4 As shown, wherein, the difference of this example is that the distance between the coupling antenna part 13 and the torch reflection end 14 is 3 / 4λ, correspondingly, for the convenience of the antenna introduction in the coupling antenna part 13, the gradient of this example The pipe 22 is provided with a slot 221 laterally, and the structure diagram of the shielding cover 2 of this example is as follows: Figure 5 As shown, the cross-sectional view is as Image 6As shown, for the same parts of this example and the first example, please refer to the specific description of the example, and details are not described in this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com