A kind of nanomotor and preparation method thereof

A motor and nanotechnology, applied in the field of nanomotors and their preparation, can solve the problems of slow movement speed and complex process, and achieve the effect of simplifying the driving mode, simplifying the preparation process, and overcoming the complex process technology or expensive equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

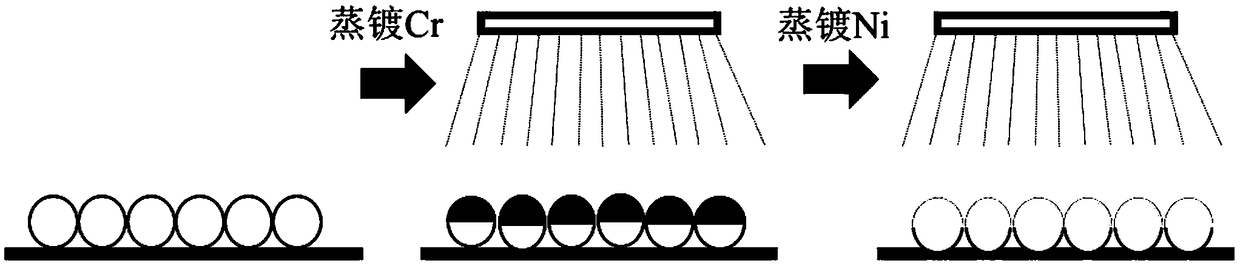

[0035] Combine below Figure 1-7 To illustrate this embodiment mode, a nanomotor described in this embodiment mode is two spheres bonded together, an adhesion layer metal and a magnetic metal are vapor-deposited on the semi-spherical surface of the spheres, and the adhesion layer metal Located between the sphere and the magnetic metal, the spheres are bonded together on one side on which the adhesive layer metal and the magnetic metal are vapor-deposited, and the diameter of the nanomotor is 500nm-40μm.

[0036] The preparation process of the nanomotor is relatively simple, and its precise control can be realized through a simple device. The adhesion layer metal improves the cohesion between the magnetic metal and the sphere. The magnetic metal plays the role of connecting the two spheres. Each sphere forms a single magnet due to the magnetization of the earth's magnetic field after evaporating the magnetic metal, and is connected to each other due to the attraction of oppos...

specific Embodiment approach 2

[0037] Combine below Figure 1-7 This implementation mode is described. This implementation mode further describes the first implementation mode. The thickness of the adhesion layer metal is 10 nm, and the thickness of the magnetic metal is 15 nm. Studies have shown that if the metal thickness of the adhesion layer is too thin, the adhesion will be reduced; if the metal thickness of the adhesion layer is too thick, it will affect the weight of the sphere, thereby affecting the movement of the motor; if the thickness of the magnetic metal is too thin, the magnetic field cannot drive the movement of the nanomotor; If the magnetic metal is too thick, the nanomotor will be dragged by the strong magnetic field. When the metal thickness of the adhesion layer is 10nm, it does not affect the movement state of the nanomotor, and at the same time plays an adhesion role; the thickness of the magnetic metal can be 10nm-90nm, and the effect of 15nm is better.

specific Embodiment approach 3

[0038] Combine below Figure 1-7 Describe this embodiment mode. This embodiment mode will further illustrate Embodiment 1 or 2. The metal of the adhesion layer is metal Cr or metal Ti, and the magnetic metal is magnetic Ni, magnetic Fe, magnetic Co, Fe-Co alloy, Fe-Ni alloy, Co-Ni alloy or Fe-Co-Ni alloy. Metal Cr or metal Ti is used as the adhesion layer, and its adhesion effect is better. Magnetic Ni, magnetic Fe, magnetic Co, Fe-Co alloy, Fe-Ni alloy, Co-Ni alloy or Fe-Co-Ni alloy are ferromagnetic materials, and the magnetism of the sphere will not fade after magnetization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com