A synchronous rectifier turn-on control method and circuit

A technology of synchronous rectifier tubes and control circuits, which is applied in the direction of control/regulation systems, electrical components, and adjustment of electrical variables. It can solve the problems of limited voltage drop slope off time, long voltage drop time, and chip use restrictions, etc., to achieve Effects of reduced size and cost, increased reliability, and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

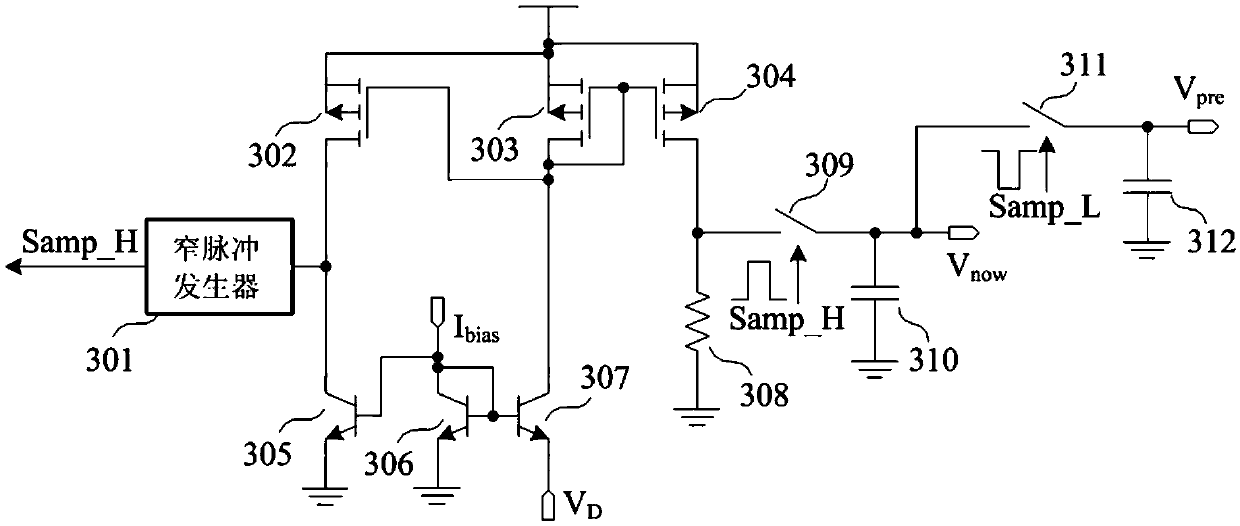

[0035] Such as image 3 As shown, it is the drain negative pressure sampling and holding circuit in the synchronous rectifier tube opening control circuit of the present invention, including narrow pulse generator 301, PMOS tube 302, PMOS tube 303, PMOS tube 304, NPN tube 305, NPN tube 306, NPN tube 307, resistor 308, switch 309, capacitor 310, switch 311, capacitor 312. The input terminal of the narrow pulse generator 301 is connected to the drain terminal of the PMOS transistor 302 and the collector of the NPN transistor 305, and the output terminal of the 301 provides the sampling signal Samp_H of each negative pressure; the source terminal of the PMOS transistor 302 is connected to the power supply , the gate terminal is connected to the drain of the PMOS transistor 303 and the collector of the NPN transistor 307; the emitter of the NPN transistor 305 is grounded, and the base is connected to the collector of the NPN transistor 306; the emitter of the NPN transistor 306 is...

Embodiment 2

[0041] Such as Figure 5 As shown, it is another structure of the drain negative pressure sample-and-hold circuit. Compared with the first embodiment, the capacitor 310 is removed, and the connection relationship between the switches 309 and 311 is changed, and other parts are the same as the first embodiment. One end of the switch 309 is connected to one end of the resistor 308, and the other end of the 309 does not need to be connected to a capacitor, and directly gives the voltage value of this sampling; one end of the switch 311 bypasses the switch 503, and is directly connected to one end of the resistor 308, and the other end of the 311 The capacitor 312 is connected to give the last sampled and saved voltage value, and the control terminal of 311 is connected to the delayed signal Samp_H2 of the sampling signal Samp_H. Samp_H2 is still a narrow pulse, which is generated by an external delay circuit, but it is delayed relative to Samp_H in time.

[0042] The Samp_H sig...

Embodiment 3

[0044] Such as Figure 6As shown, it is another structure of the drain negative pressure sample-and-hold circuit. The resistor 308 in Embodiment 1 is removed, and a third switch 601 is added; one end of the third switch 601 is connected to the upper plate of the capacitor 310 , the other end of 601 is grounded, and the control end of 601 is connected to the sampling signal Samp_H3 . The partial signal Samp_H3 of the sampling signal Samp_H first discharges the charge of the capacitor 310 to initialize the capacitor. The falling edge of the partial signal Samp_H3 arrives before the falling edge of Samp_H. During the period when Samp_H is at high level and Samp_H3 is at low level, the negative voltage is converted into current, and the capacitor 310 is charged through the PMOS transistor 304 . Thereafter, Samp_H becomes low level, and the inversion signal Samp_L becomes high level, the switch 311 is turned on, and the voltage on the capacitor 312 is refreshed. The capacitance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com