Biomass particle tobacco dryer capable of achieving automatic slag removing

A biomass particle, automatic slag removal technology, applied in the fields of tobacco, food science, tobacco preparation, etc., can solve the problems of affecting biomass fuel combustion, insufficient fuel combustion, hidden dangers of burners, etc., and achieve simple and compact combustion structure and equipment. Reasonable and compact structure, smooth combustion and full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

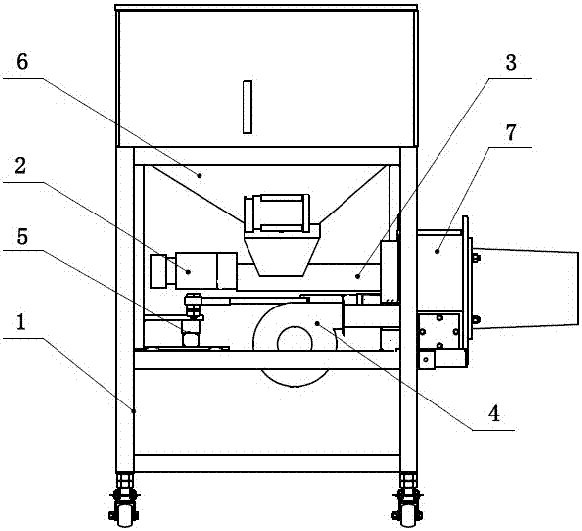

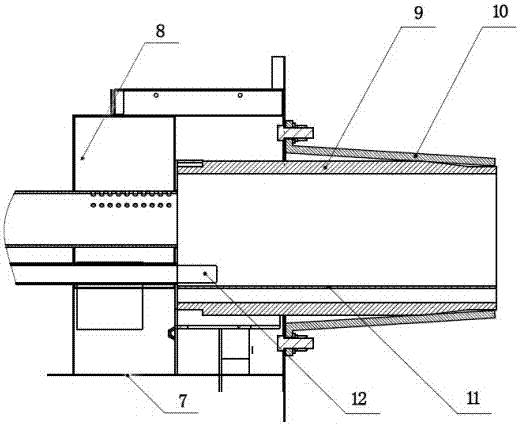

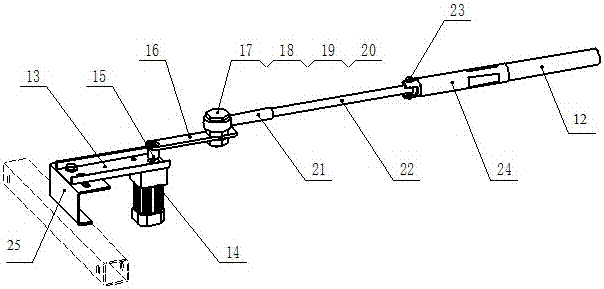

[0024] Such as figure 1 , 2 An automatic slag-removing biomass particle flue-cured machine is shown, which includes a support frame 1 and a combustion device installed on the support frame 1. The support frame 1 is a movable and / or height-adjustable support. The combustion device includes a feed pipe 3 and a combustion pool 9. The discharge port of the feed pipe 3 communicates with the combustion pool 9. A reciprocating propulsion slag removal device 5 is installed below the feed pipe 3. The slag removal device 5 includes a rocker 16, a connecting rod 22. Slagging rod 12, fixed slideway 24; one end of the rocker 16 is movably connected with one end of the connecting rod 22, and the other end of the connecting rod 22 is movably connected with the slag removing rod 12, and the slag removing rod 12 is reciprocated in the fixed slideway 24. For slag movem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com