A circular chain heat treatment device and its application method

A technology of heat treatment device and circular chain, applied in heat treatment furnace, heat treatment equipment, quenching device, etc., can solve problems such as difficulty in meeting the requirements of hardness and strength of circular chain, fine austenite grains, long heating cycle, etc. , to achieve the effect of high work efficiency, high wear resistance and bearing capacity, and elimination of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

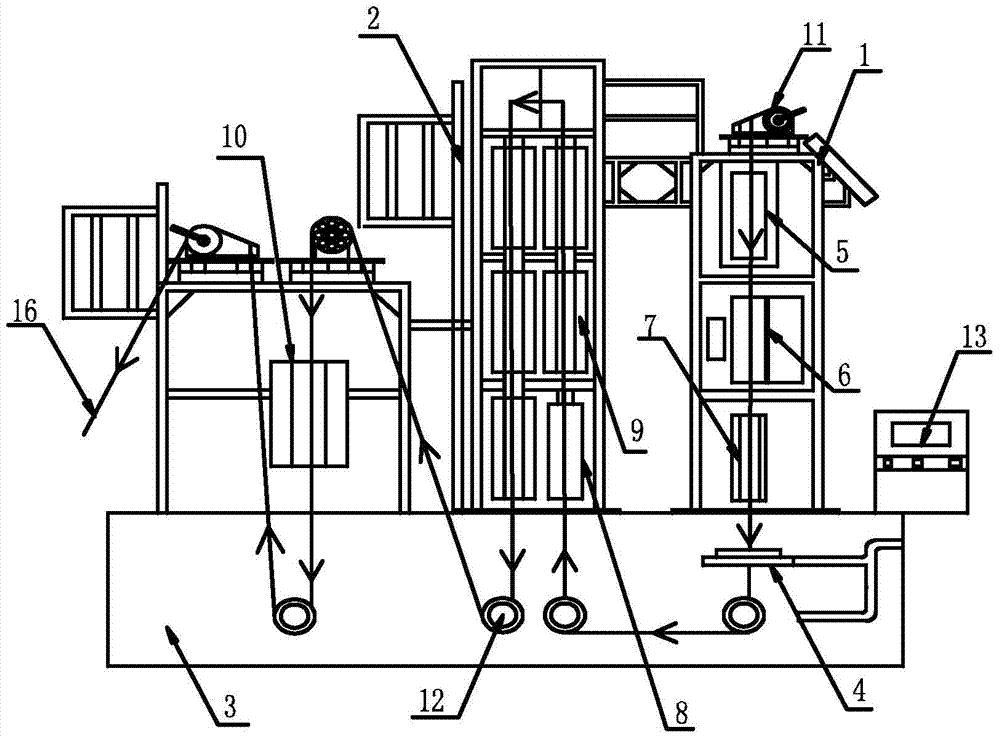

[0041] Such as figure 1 , Figure 5 As shown, a heat treatment device for a circular link chain includes a quenching part 1 and a tempering part 2 arranged in sequence. The quenching part 1 and the tempering part 2 are all provided with a cooling part 3, which can complete the circular chain at one time. Advanced heat treatment process, high degree of integration, high work efficiency.

[0042] The quenching part 1 is provided with a quenching temperature regulating box 7, and a preheating heating box 5 and an austenitizing heating box 6 are arranged in sequence before the quenching temperature regulating box 7, and the circular link chain 16 is installed in the preheating heating box 5. When the austenitizing heating box 6 moves at a constant speed, it is continuously heated. Due to the characteristics of induction hardening, when the temperature is high, the temperature of the straight arm 161 of the circular link chain 16 is much lower than the temperature of the shoulder ...

Embodiment 2

[0047] Such as figure 1 , Figure 5 As shown, the tempering section 2 is sequentially provided with a uniform temperature tempering heating box 8, at least one tempering temperature regulating box 9, and a differential temperature tempering heating box 10, and the uniform temperature tempering heating box 8 ensures that the circular chain The shoulder top 162 is fully tempered at the set temperature, which helps to eliminate internal stress, and promotes the shoulder top 162 of the round chain link to have higher wear resistance and load carrying capacity. The set temperature of the tempering temperature regulating box 9 350-400°C, between the uniform temperature tempering heating box 8 and the differential temperature tempering heating box 10, there are 4-6 tempering temperature regulating boxes 9, and along the moving direction of the circular chain, Adjacent tempering temperature control boxes 9 are connected in sequence, which helps to reduce the contact time between the ...

Embodiment 3

[0054] In this embodiment, the specification of the circular link chain 16 is Φ38mm×137mm, and the number of the tempering temperature control boxes 9 is set to 4, and the heat treatment of the circular link chain 16 includes the following steps:

[0055] (1) Connect the round link chain 16 with the traction chain, and pass the traction chain through the quenching part 1 and the tempering part 2 sequentially through the transmission part, start the control part 13, and preheat the quenching and tempering box 7 To 950°C, preheat the tempering temperature control box 9 to 350°C, 370°C, 390°C, 400°C in sequence;

[0056] (2) Under the cooperation of the driving guide sprocket 11 and the driven guide sprocket 12, the circular link chain 16 moves at a constant speed under the traction of the traction chain;

[0057] (3) The circular link chain 16 enters the preheating heating box 5 and the austenitizing heating box 6 successively for heating, and the heating time is respectively 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com