Acid-resistant etching protection ink and its preparation method and construction method

An etching protection and ink technology, which is applied in ink, printing, household utensils, etc., can solve the problems of high ink price, long deinking time, irritating sour smell, etc., and achieve high production efficiency and shorten deinking time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

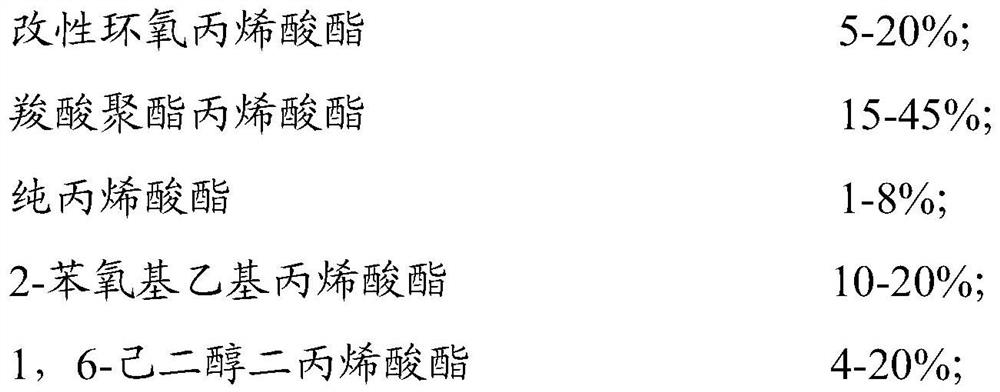

[0051] The acid-resistant etching protective ink of this embodiment comprises the following components in weight percent:

[0052]

[0053]

[0054] in,

[0055] The acid value of the carboxylic polyester acrylate is 190-220 mg KOH / g, and the number average molecular weight is 4500-6000.

[0056] The preparation method of the acid-resistant etching protection printing ink of embodiment 1, comprises the steps:

[0057] (1) Weighing components: take each component according to weight percentage, and set aside;

[0058] (2) Ingredients and dispersion: the weighed 2-phenoxyethyl acrylate, 1,6-hexanediol diacrylate, 2-hydroxy-2-methyl-1-phenyl-1-propanone, Mix 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, carboxylic acid polyester acrylate, pure acrylate and modified epoxy acrylate, after uniform dispersion, add 8000 mesh talcum powder, BYK333, Stir the homemade blue paste evenly to obtain the glue;

[0059] (3) Dispersion and grinding: disperse the rubber material descri...

Embodiment 2

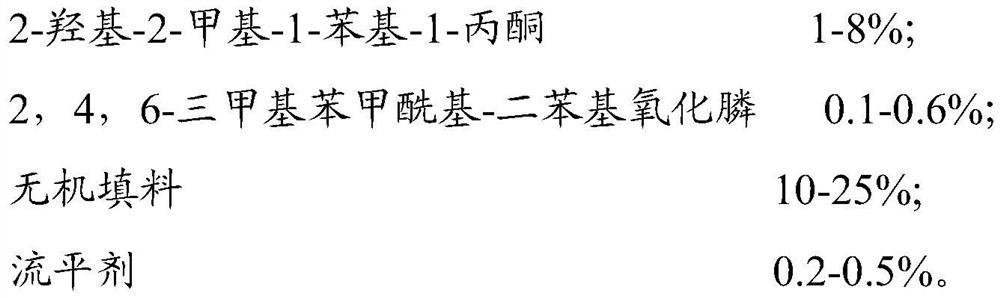

[0068] The acid-resistant etching protective ink of this embodiment comprises the following components in weight percent:

[0069]

[0070] in,

[0071] The acid value and number average molecular weight of described carboxylic acid polyester acrylate are the same as in Example 1.

[0072] Example 2 The preparation method and construction method of the acid-resistant etching protection ink are the same as in Example 1.

Embodiment 3

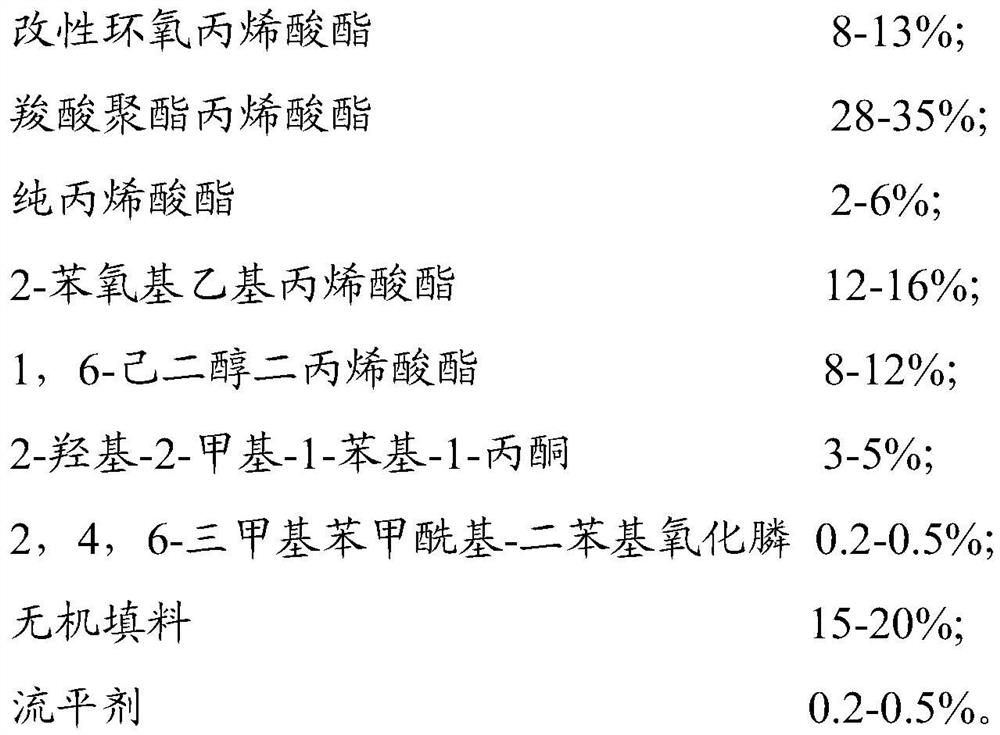

[0074] The acid-resistant etching protective ink of this embodiment comprises the following components in weight percent:

[0075]

[0076]

[0077] in,

[0078] The acid value and number average molecular weight of described carboxylic acid polyester acrylate are the same as in Example 1.

[0079] Example 3 The preparation method and construction method of the acid-resistant etching protection ink are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com