Method and device for separating printing ink from fibers by dry-process magnetic force difference coupled vibration

A technology of coupling vibration and fiber, applied in the direction of fiber raw material, raw material separation, fiber raw material processing, etc., can solve the problems that the magnetic field cannot be quantified and estimated, ink cannot be effectively removed, and fiber bleaching and washing processes are added.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

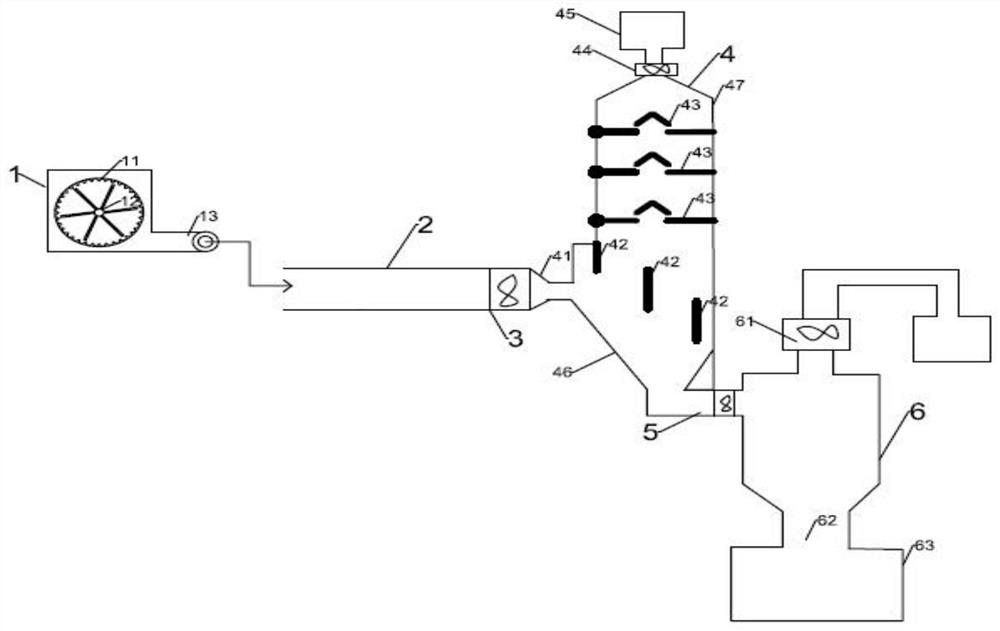

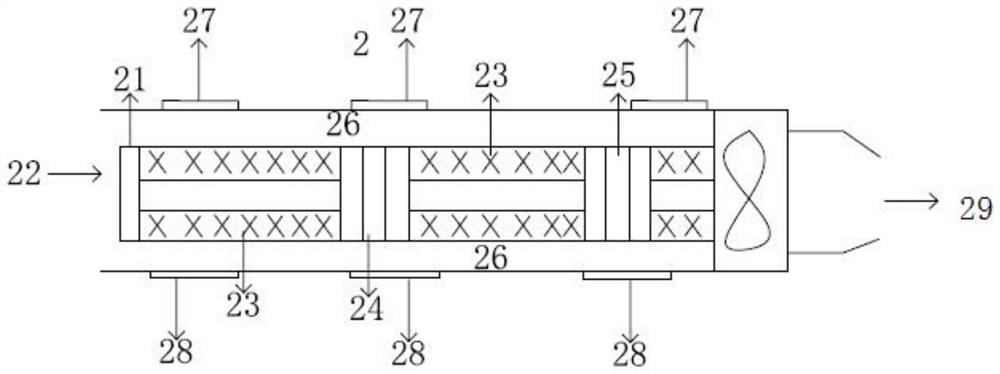

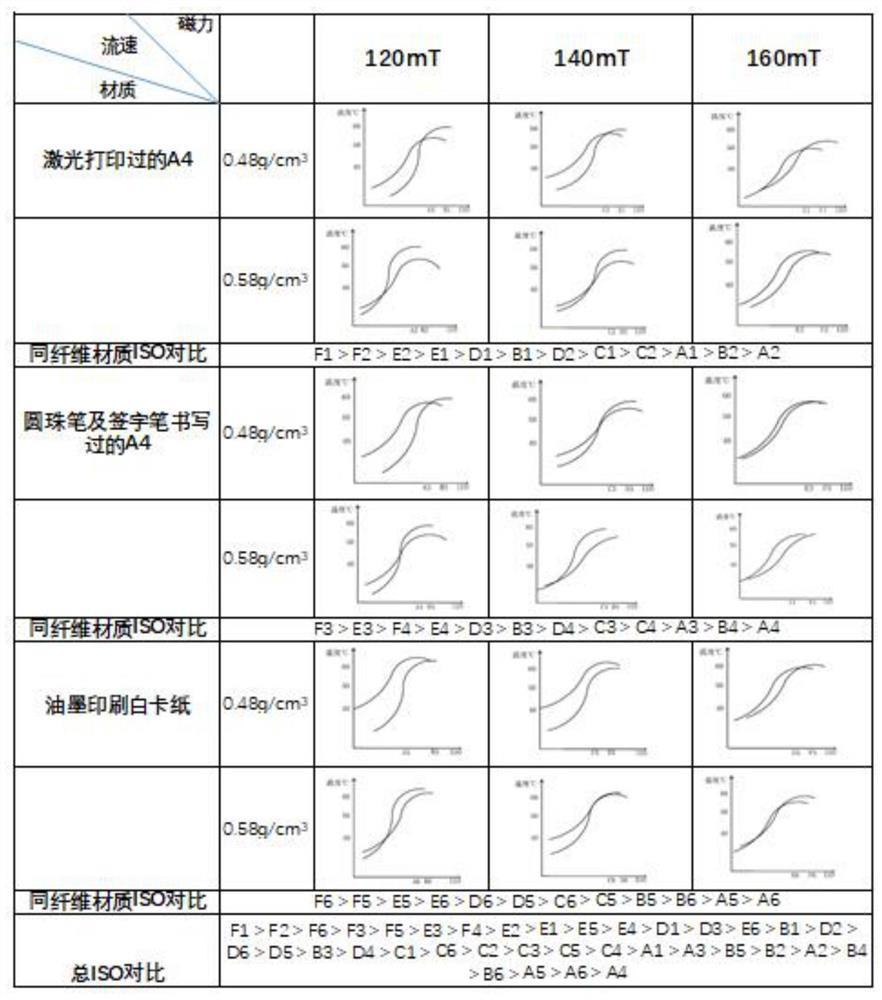

[0040] Such as figure 1 , figure 2 , a dry-process magnetic force difference coupling vibration separation equipment for ink and fiber, including a fiber crushing machine unit 1, a magnetic force difference coupling vibrator 2, an accelerating fan 3, a ballistic rebound sucker 4, and a material settlement conveying pipe connected in sequence through pipelines 5. Cylindrical separator 6, wherein the center of the fiber inlet 22 end to the fiber outlet 29 end in the shell of the magnetic force difference coupling vibrator 2 is provided with a magnet guide piece 21 connected in sequence, a continuous row of iron and a coil 23, and a same-polar near-frequency guide. The magnet sheet 24, the magnetic shielding structure 25, the cavity in the housing of the magnetic force difference coupling vibrator 2 constitute the oscillation domain 26, the outer side of the housing is provided with a temperature controller 27 and a thermostat 28, and the middle part of the ballistic rebound suc...

Embodiment 2

[0046] Such as figure 1 , figure 2 , a dry-process magnetic force difference coupling vibration separation equipment for ink and fiber, including a fiber crushing machine unit 1, a magnetic force difference coupling vibrator 2, an accelerating fan 3, a ballistic rebound sucker 4, and a material settlement conveying pipe connected in sequence through pipelines 5. Cylindrical separator 6, wherein the center of the fiber inlet 22 end to the fiber outlet 29 end in the shell of the magnetic force difference coupling vibrator 2 is provided with a magnet guide piece 21 connected in sequence, a continuous row of iron and a coil 23, and a same-polar near-frequency guide. The magnet sheet 24, the magnetic shielding structure 25, the cavity in the housing of the magnetic force difference coupling vibrator 2 constitute the oscillation domain 26, the outer side of the housing is provided with a temperature controller 27 and a thermostat 28, and the middle part of the ballistic rebound suc...

Embodiment 3

[0052] Such as figure 1 , figure 2 , a dry-process magnetic force difference coupling vibration separation equipment for ink and fiber, including a fiber crushing machine unit 1, a magnetic force difference coupling vibrator 2, an accelerating fan 3, a ballistic rebound sucker 4, and a material settlement conveying pipe connected in sequence through pipelines 5. Cylindrical separator 6, wherein the center of the fiber inlet 22 end to the fiber outlet 29 end in the shell of the magnetic force difference coupling vibrator 2 is provided with a magnet guide piece 21 connected in sequence, a continuous row of iron and a coil 23, and a same-polar near-frequency guide. The magnet sheet 24, the magnetic shielding structure 25, the cavity in the housing of the magnetic force difference coupling vibrator 2 constitute the oscillation domain 26, the outer side of the housing is provided with a temperature controller 27 and a thermostat 28, and the middle part of the ballistic rebound suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com