Preparation method of highly magneto-rheological silicone rubber-based magneto-rheological elastomer

A magnetorheological elastomer and rheological technology, applied in the field of magnetorheological materials, can solve the problems of reducing the magnetorheological properties of elastomers, poor mechanical properties of composite elastomers, and affecting the scope of use, so as to improve the distribution and magnetic flow Increased variable effect and improved rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

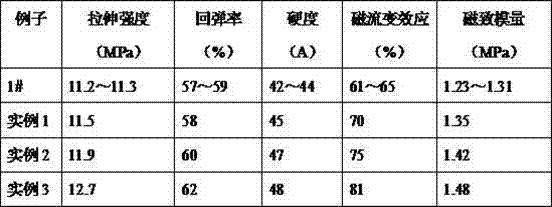

Examples

example 1

[0013] First, mix ferric citrate and ferric nitrate with deionized water at a mass ratio of 1:1:10, and mix at 45°C for 15 minutes to prepare a mixed solution of iron ions. Then, at a mass ratio of 1:5, mix 100 mesh Graphite oxide was stirred and mixed with iron ion mixture for 25 minutes, then left to age for 3 hours, and then dried at 65°C for 6 hours; after the drying was completed, dry crystals were obtained and placed in a crucible, and heated at a rate of 10°C / min to 550°C, heat preservation and calcination for 1 hour, then let it stand and cool to room temperature to obtain calcined granules. Stir and mix the calcined granules and carbonyl iron powder at a mass ratio of 1:5, then ball mill at 350r / min for 2 hours, and pass through a 200-mesh sieve to obtain mixed ball mills. powder; according to the mass ratio of 1:8, mix the mixed ball mill powder and liquid silicone rubber LSR and place it in a high-speed shearing machine. After shearing for 25 minutes, ultrasonically ...

example 2

[0015] First, according to the mass ratio of 1:1:10, ferric citrate and ferric nitrate were stirred and mixed with deionized water, and after mixing at 48°C for 18 minutes, the iron ion mixed solution was prepared, and then according to the mass ratio of 1:5, 100 mesh Graphite oxide was stirred and mixed with the iron ion mixture for 28 minutes, then left to age for 4 hours, and then dried at 68°C for 7 hours; after the drying was completed, the dried crystals were obtained and placed in a crucible, and heated at a rate of 10°C / min to Calcined at 580°C for 2 hours and then cooled to room temperature to obtain calcined particles. The calcined particles and carbonyl iron powder were stirred and mixed at a mass ratio of 1:5, and then ball milled at 380r / min for 3 hours, and passed through a 200-mesh sieve to obtain a mixed ball mill. powder; according to the mass ratio of 1:8, the mixed ball mill powder and liquid silicone rubber LSR were stirred and mixed and placed in a high-spe...

example 3

[0017] First, according to the mass ratio of 1:1:10, ferric citrate and ferric nitrate were stirred and mixed with deionized water, and after mixing at 50°C for 20 minutes, the iron ion mixed solution was prepared, and then according to the mass ratio of 1:5, 100 mesh Graphite oxide was stirred and mixed with the iron ion mixture for 30 minutes, then left to age for 5 hours, and then dried at 70°C for 8 hours; after the drying was completed, dry crystals were obtained and placed in a crucible, and heated at a rate of 10°C / min to Calcined at 600°C for 2 hours and then cooled to room temperature to obtain calcined particles. The calcined particles and carbonyl iron powder were stirred and mixed at a mass ratio of 1:5, and then ball milled at 400r / min for 3 hours, and passed through a 200-mesh sieve to obtain a mixed ball mill. powder; according to the mass ratio of 1:8, mix the mixed ball mill powder and liquid silicone rubber LSR and place it in a high-speed shearing machine. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com