Degradable foaming package material and preparation method thereof

A packaging material and foaming agent technology, applied in the field of degradable foam packaging materials, can solve the problems of difficult preparation of foam materials, poor compatibility between degradable plastics and natural fibers, etc., so as to reduce repulsion and production costs. , the effect of accelerating the crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

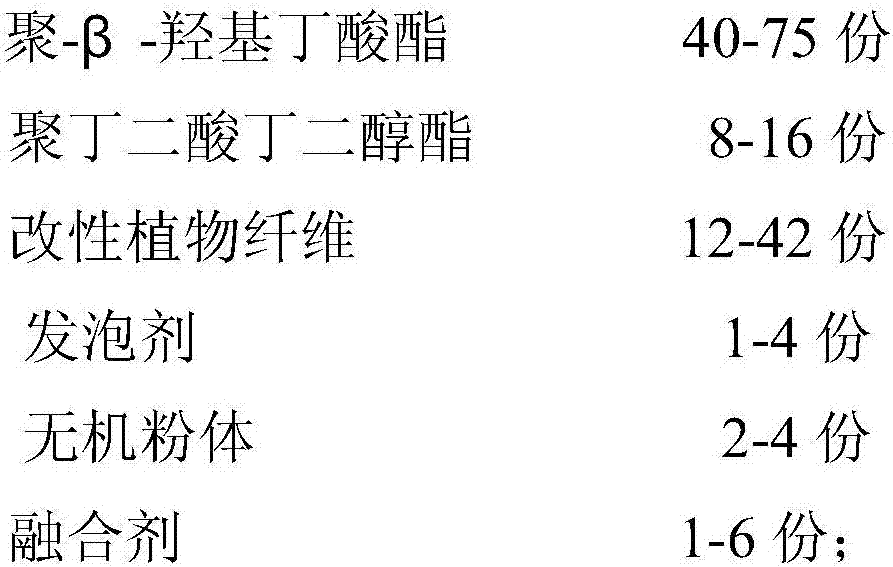

[0024] The raw material of the degradable foam packaging material of this embodiment consists of the following parts by weight:

[0025] 75 parts of poly-β-hydroxybutyrate (PHB);

[0026] 8 parts of polybutylene succinate (PBS);

[0027] 12 parts corn stalks;

[0028] 2 parts of ammonium bicarbonate;

[0029] 2 parts talcum powder;

[0030] 1 part of acetic anhydride;

[0031] First, modify the corn stalks, and dry them in an oven until the water content is 5% at 2-5MPa, 240°C, under the protection of nitrogen; Treat with X-rays for 5 minutes under nitrogen protection to obtain modified corn stalk powder;

[0032] The preparation method of degradable foam packaging material in the present embodiment comprises the following steps:

[0033] (1) Prepare materials by weighing poly-β-hydroxybutyrate, polybutylene succinate, modified corn stalk powder, ammonium bicarbonate, talcum powder, and acetic anhydride according to the formula ratio;

[0034] (2) Under the condition of...

Embodiment 2

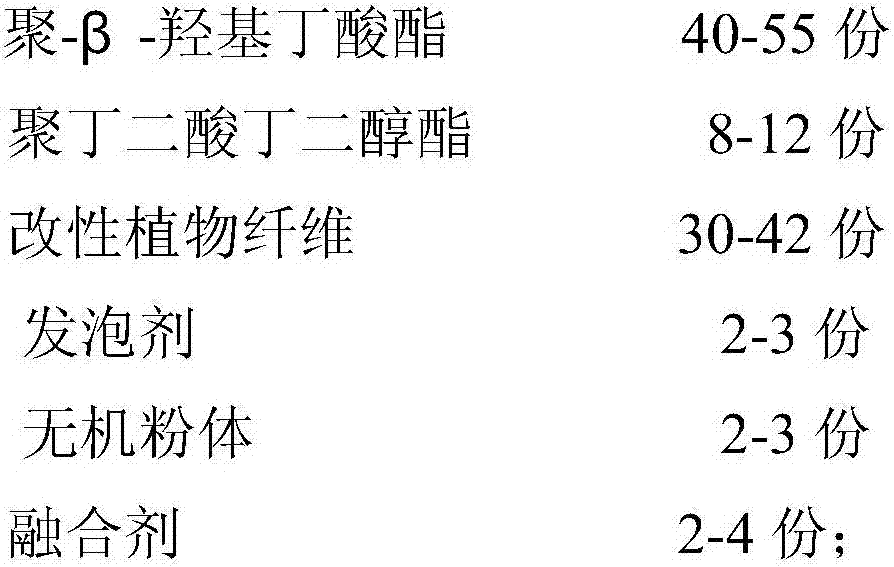

[0037] The raw material of the degradable foam packaging material of this embodiment consists of the following parts by weight:

[0038] 70 parts of poly-β-hydroxybutyrate (PHB);

[0039] 10 parts of polybutylene succinate (PBS);

[0040] 14 parts of bamboo fiber;

[0041] 2 parts sodium bicarbonate;

[0042] 3 parts calcium carbonate;

[0043] 1 part of phthalic anhydride;

[0044] Firstly, the bamboo fiber is modified, and dried in an oven to a moisture content of 4% at 2-5MPa, 220°C, under nitrogen protection; then the bamboo fiber powder crushed to a particle size of 80 mesh sieve is Treated with X-rays for 10 minutes under nitrogen protection to obtain modified bamboo fiber powder;

[0045] The preparation method of degradable foam packaging material in the present embodiment comprises the following steps:

[0046] (1) Take poly-β-hydroxybutyrate, polybutylene succinate, modified bamboo fiber powder, sodium bicarbonate, calcium carbonate, phthalic anhydride and prep...

Embodiment 3

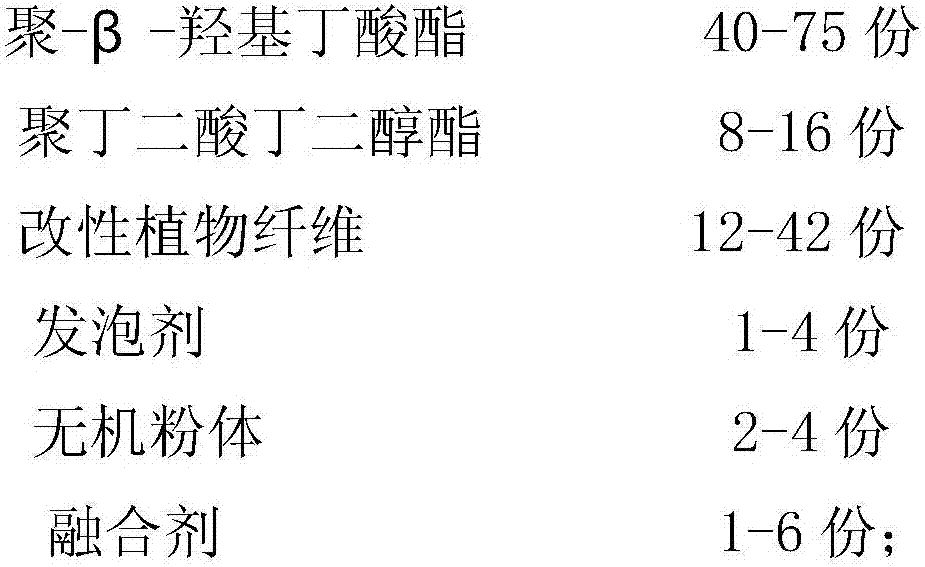

[0050] The raw material of the degradable foam packaging material of this embodiment consists of the following parts by weight:

[0051] 65 parts of poly-β-hydroxybutyrate (PHB);

[0052] 12 parts of polybutylene succinate (PBS);

[0053] 17 parts of hemp fiber;

[0054] 2 parts of azodicarbonamide;

[0055] 1 part of talcum powder, 1 part of calcium carbonate;

[0056] 1 part of phthalic anhydride, 1 part of polyetheramine;

[0057] First modify the hemp fiber, and dry it in an oven to a moisture content of 3% at 2-5MPa, 240°C, under the protection of nitrogen; then crush the hemp fiber powder with a particle size of 80 mesh, Treated with X-rays for 5 minutes under nitrogen protection to obtain modified hemp fiber powder;

[0058] The preparation method of degradable foam packaging material in the present embodiment comprises the following steps:

[0059] (1) Mix poly-β-hydroxybutyrate, polybutylene succinate, modified hemp fiber powder, azodicarbonamide, talcum powder, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com