Foam glass suitable for interior decoration and production technology of foam glass

A foam glass and interior decoration technology, which is applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of thermal insulation effect, sound insulation effect and strength to be improved, and achieve improved thermal insulation and sound insulation effects, Improve foam expansion ability and promote foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

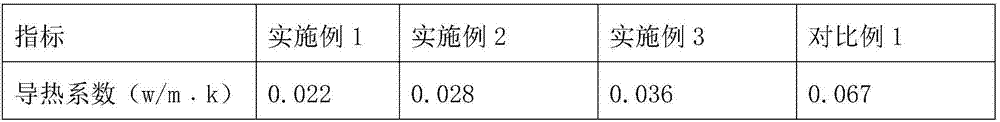

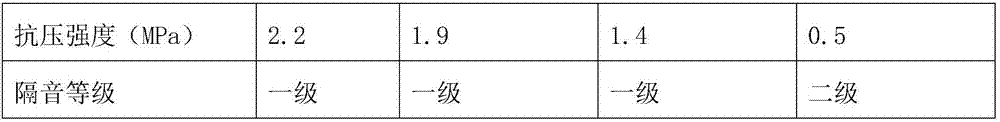

Examples

Embodiment 1

[0030] A foam glass suitable for interior decoration, comprising the following raw materials in parts by weight: 105 parts of waste flat glass, 35 parts of fly ash, 4 parts of silicon micropowder, 6 parts of foaming agent, 4 parts of flux, and 1.2 parts of foam stabilizer , 4.2 parts of surfactant, 2 parts of release agent and 1.7 parts of foam accelerator.

[0031] The foaming agent is graphite, which is conducive to the formation of foamed glass with a thin and uniform closed pore structure, and improves the thermal insulation and sound insulation effects of the foamed glass.

[0032] The flux is manganese dioxide, which helps to adjust the surface properties of the glass particles, reduces the viscosity of the glass, and makes the glass easy to melt.

[0033] Foam stabilizers are phosphates that help stabilize the cell structure by preventing the cells from combining with each other to form interconnected cells or from collapsing.

[0034] The surfactant is industrial alco...

Embodiment 2

[0044] A foam glass suitable for interior decoration, comprising the following raw materials in parts by weight: 100 parts of waste flat glass, 25 parts of fly ash, 2 parts of silicon micropowder, 5 parts of foaming agent, 2 parts of flux, and 0.9 parts of foam stabilizer , 2.4 parts of surfactant, 1 part of release agent and 1 part of foam accelerator.

[0045] The foaming agent is graphite, which is conducive to the formation of foamed glass with a thin and uniform closed pore structure, and improves the thermal insulation and sound insulation effects of the foamed glass.

[0046] The flux is manganese dioxide, which helps to adjust the surface properties of the glass particles, reduces the viscosity of the glass, and makes the glass easy to melt.

[0047] Foam stabilizers are phosphates that help stabilize the cell structure by preventing the cells from combining with each other to form interconnected cells or from collapsing.

[0048] The surfactant is industrial alcohol,...

Embodiment 3

[0058] A foam glass suitable for interior decoration, comprising the following raw materials in parts by weight: 110 parts of waste flat glass, 45 parts of fly ash, 6 parts of silicon micropowder, 7 parts of foaming agent, 6 parts of flux, and 1.5 parts of foam stabilizer , 6.0 parts of surfactant, 3 parts of release agent and 2.4 parts of foam accelerator.

[0059] The foaming agent is graphite, which is conducive to the formation of foamed glass with a thin and uniform closed pore structure, and improves the thermal insulation and sound insulation effects of the foamed glass.

[0060] The flux is manganese dioxide, which helps to adjust the surface properties of the glass particles, reduces the viscosity of the glass, and makes the glass easy to melt.

[0061] Foam stabilizers are phosphates that help stabilize the cell structure by preventing the cells from combining with each other to form interconnected cells or from collapsing.

[0062] The surfactant is industrial alco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com