Door and window joint and construction method thereof

A construction method, door and window technology, applied in the direction of building components, building structure, thermal insulation, etc., can solve the problems of failure to form good thermal insulation performance, poor sealing, etc., achieve convenient installation, convenient construction, and solve the effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

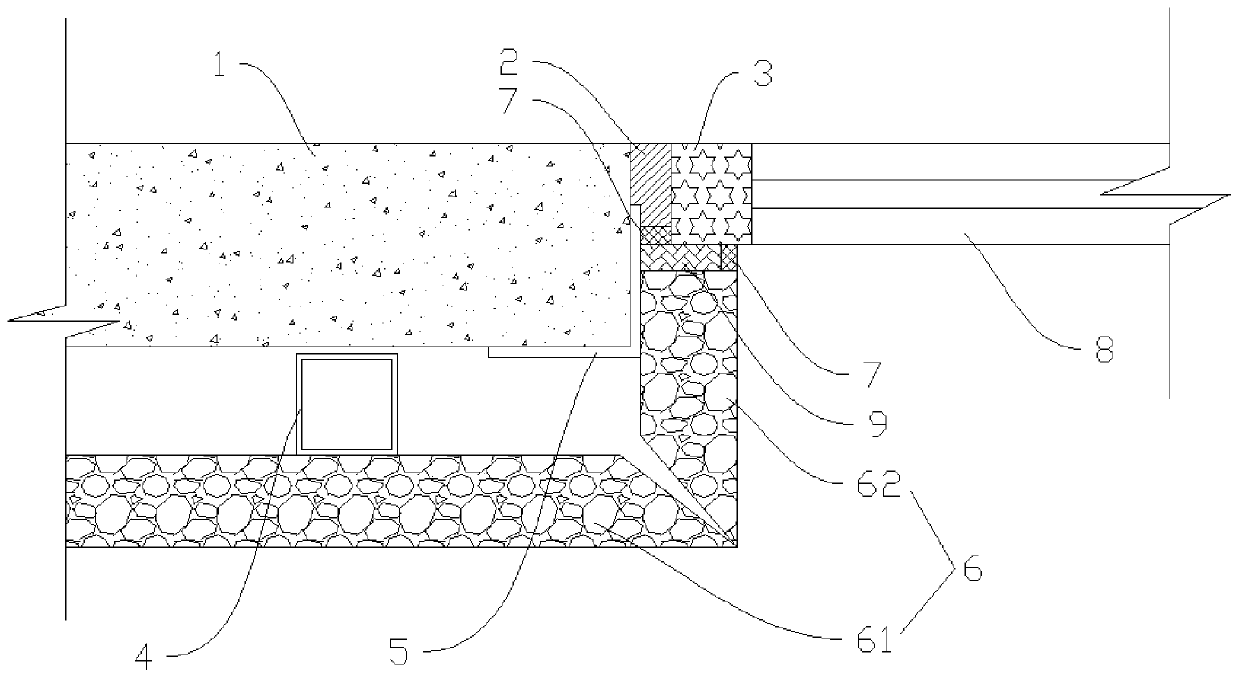

[0027] figure 1 It is a structural schematic diagram of an embodiment of the door and window node of the present invention, refer to figure 1 , the door and window joint is used at the connection between the door frame or window frame 8 and the outer wall 1, the door and window joint provided by the embodiment of the present invention includes the door and window sub-frame 3, the outer wall 1, the insulation layer 6 and the keel 4, wherein:

[0028] The edge of the door and window sub-frame 3 is connected to the edge of the outer wall 1, and a first seal 2 is arranged in the first gap formed between the outer wall 1 and the door and window sub-frame 3, and the outer side of the first seal 2 is sealed by a sealant 7. glue seal to realize the heat preservation and sealing of the first gap. The first sealing member 2 can be formed by pouring PU polyurethane foaming agent into the first gap, and then applying a sealant 7 on the outside for sealing.

[0029] The thermal insulatio...

Embodiment 2

[0036] This embodiment provides a construction method of door and window joints (refer to figure 1 ):

[0037] Connect the door and window sub-frame 3 to the outer wall 1, set the first sealing member 2 in the first gap formed between the frame body of the door and window sub-frame 3 and the outer wall 1, and seal the outer side of the first sealing member 2 Glue 7 is used for glue sealing to form a seal between the door and window sub-frame 3 and the outer wall 1;

[0038] Connect the keel 4 on the outer side of the outer wall 1, and detachably connect the insulation layer 6 to the keel 4;

[0039] A second sealing member 9 is arranged in the second gap formed between the insulation layer 6 and the sub-frame of the door and window 3 , and the outside of the second sealing member 9 is sealed with a sealant 7 .

[0040] Among them, the outer wall 1 is formed by vertical installation of ALC slats; when installing the ALC slats, according to the layout diagram of the ALC outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com