Transportation equipment for paper-making packing area

A technology of transportation equipment and installation blocks, which is applied in the field of transportation equipment in the papermaking and packaging area, which can solve the problems of long moving time, no protective measures for paper, and low stability, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

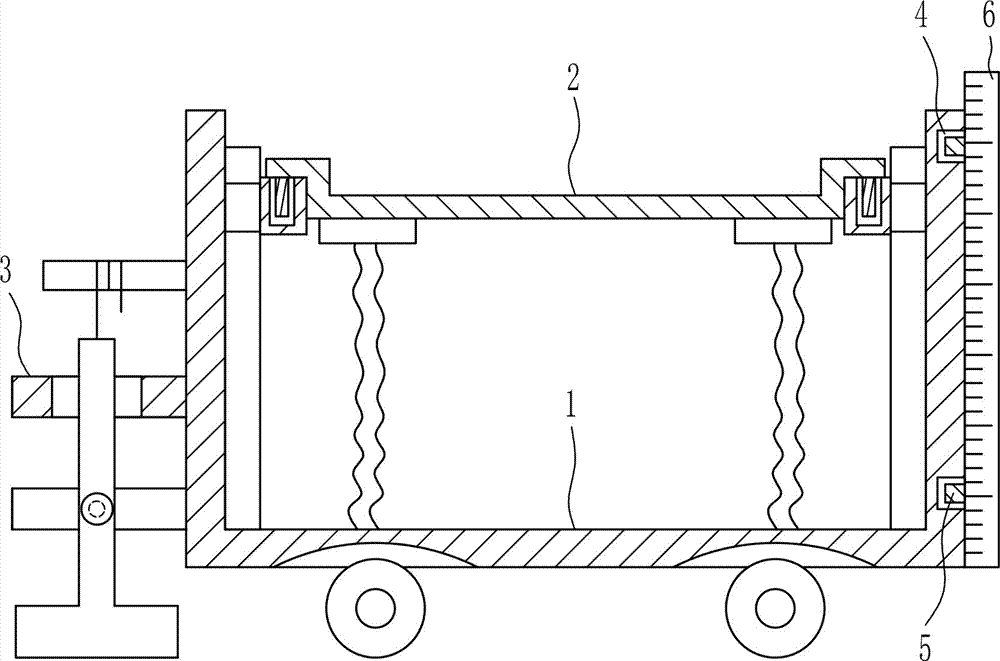

[0037] A kind of transportation equipment for paper-making and packaging area, such as Figure 1-7 As shown, it includes a trolley 1, a lifting mechanism 2 and a stabilizing mechanism 3, the trolley 1 is provided with a lifting mechanism 2, and the left side of the trolley 1 is connected with a lifting mechanism 2.

Embodiment 2

[0039] A kind of transportation equipment for paper-making and packaging area, such as Figure 1-7 As shown, it includes a trolley 1, a lifting mechanism 2 and a stabilizing mechanism 3, the trolley 1 is provided with a lifting mechanism 2, and the left side of the trolley 1 is connected with a lifting mechanism 2.

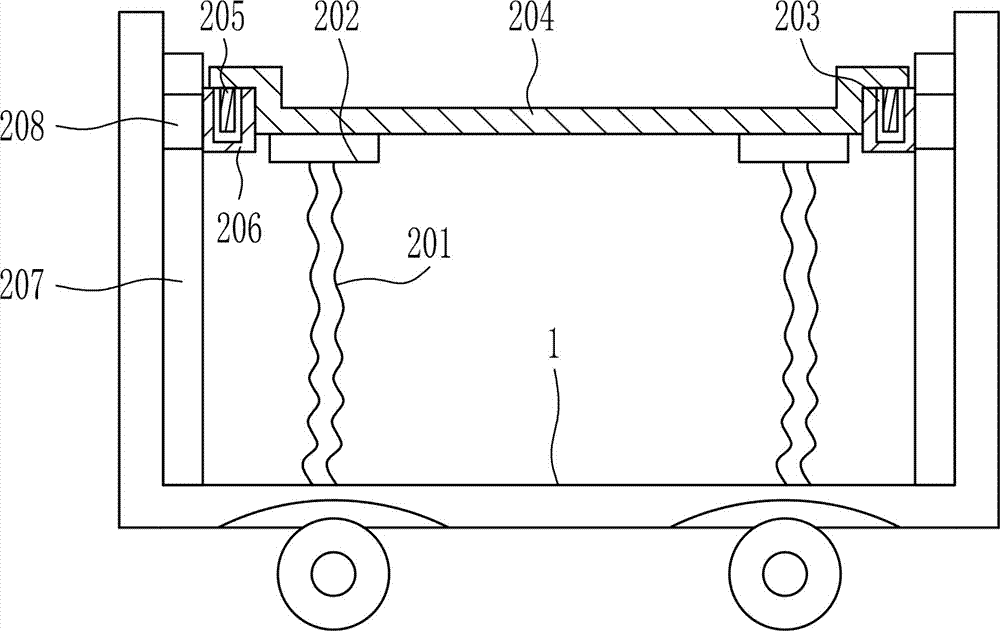

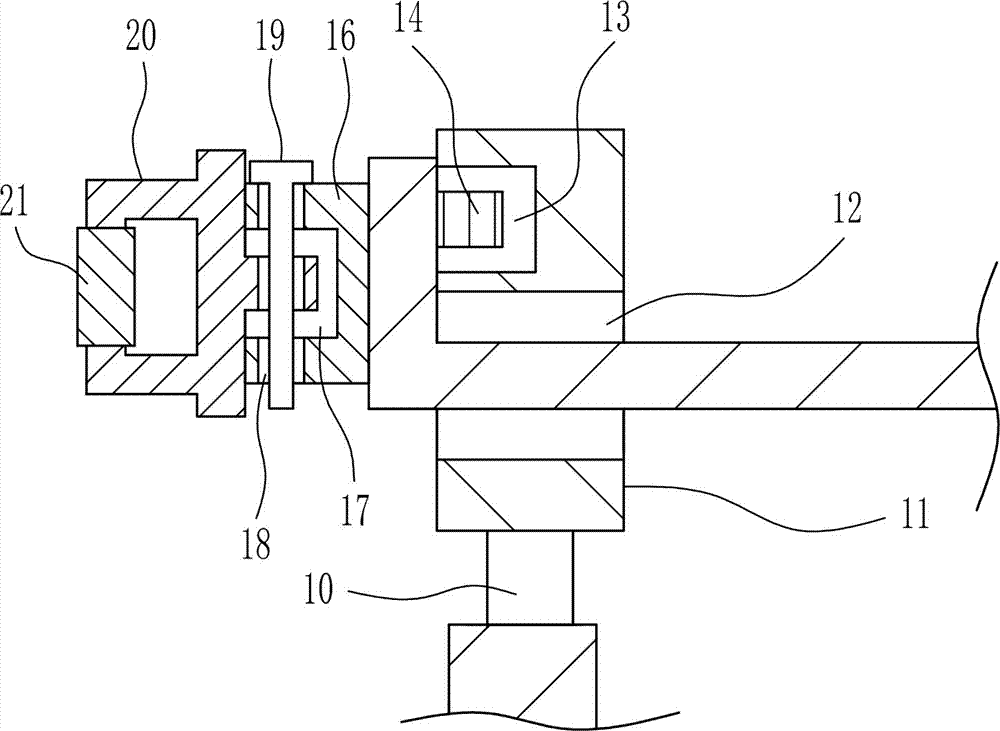

[0040] The lifting mechanism 2 includes a spring 201, a supporting block 202, a lifting plate 204, a first clamping block 205, a first mounting block 206, a slide rail 207 and a slide block 208, and the left and right sides of the cart 1 are connected with slide rails 207 , the slide rails 207 are slidingly connected with sliders 208, the sliders 208 cooperate with the slide rails 207, the inner sides of the sliders 208 are connected with the first mounting blocks 206, and the first mounting blocks 206 are provided with first grooves 203, the first block 205 is provided in the first groove 203, and the first block 205 is matched with the first groove 203, and the ...

Embodiment 3

[0042] A kind of transportation equipment for paper-making and packaging area, such as Figure 1-7 As shown, it includes a trolley 1, a lifting mechanism 2 and a stabilizing mechanism 3, the trolley 1 is provided with a lifting mechanism 2, and the left side of the trolley 1 is connected with a lifting mechanism 2.

[0043] The lifting mechanism 2 includes a spring 201, a supporting block 202, a lifting plate 204, a first clamping block 205, a first mounting block 206, a slide rail 207 and a slide block 208, and the left and right sides of the cart 1 are connected with slide rails 207 , the slide rails 207 are slidingly connected with sliders 208, the sliders 208 cooperate with the slide rails 207, the inner sides of the sliders 208 are connected with the first mounting blocks 206, and the first mounting blocks 206 are provided with first grooves 203, the first block 205 is provided in the first groove 203, and the first block 205 is matched with the first groove 203, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com