Preparation method of glass surface with partial frosted area

A glass surface and frosting technology, which is applied in the direction of abrasive material feeding device, abrasive material, manufacturing tools, etc., can solve the problems that cannot be properly solved, such as the step difference of the glass surface and the straightness of the dividing line, so as to achieve no different color on the sand surface and poor unevenness, easy popularization and application, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

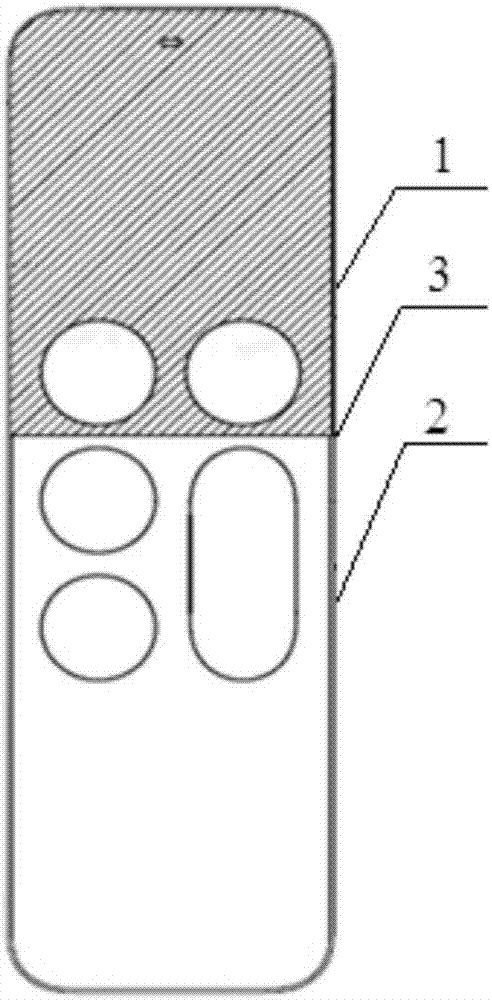

[0039] The invention provides a method for preparing the glass surface of an Apple TV remote control, such as figure 1 As shown, the glass surface includes a frosted area 1 and a sand-free area 2, the boundary line 3 between the frosted area 1 and the sand-free area 2 is a straight line, and the preparation method includes the following steps:

[0040] Screen printing protective ink: superimpose silk screen printing two layers of acid-resistant ink on the sand-free area 2, the thickness of the two layers of acid-resistant ink is 8-20 μm in total;

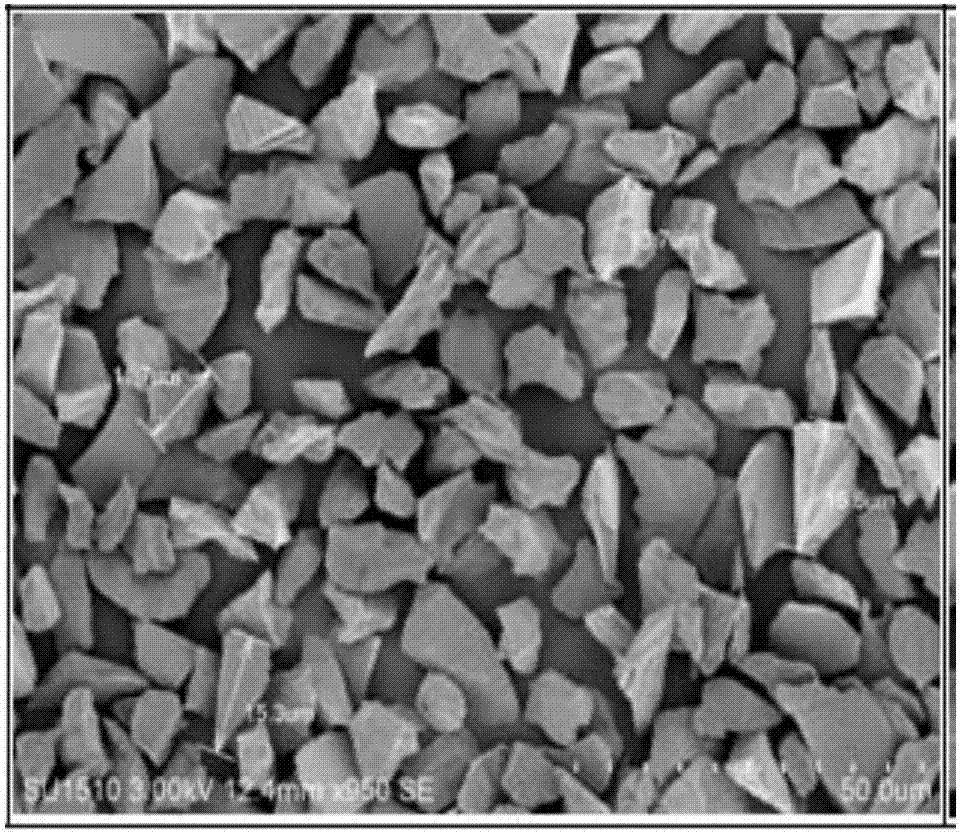

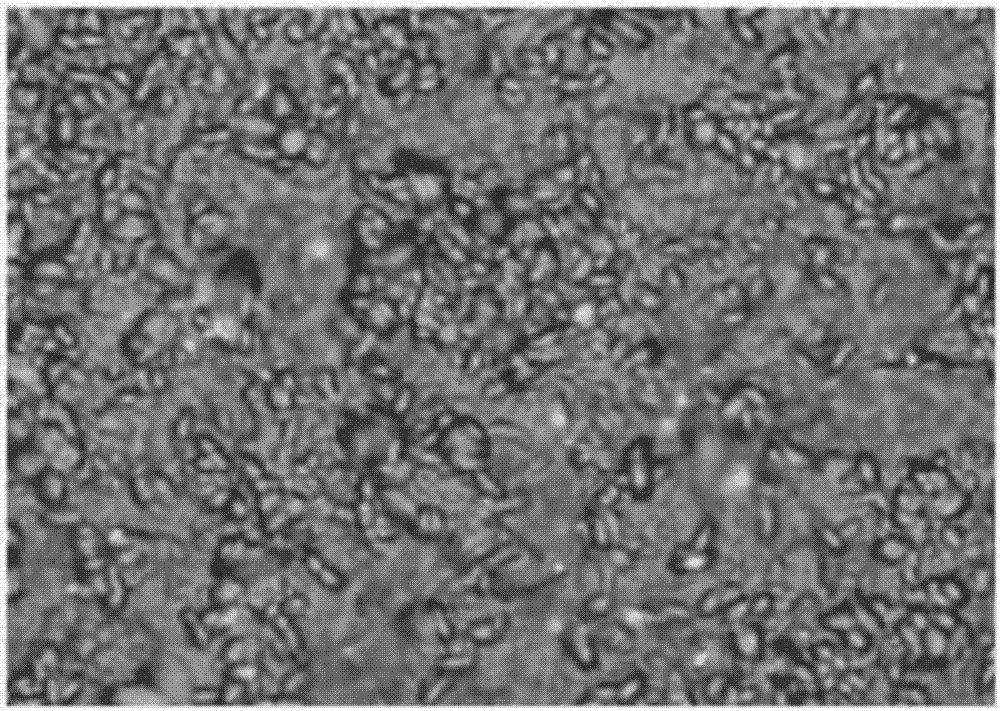

[0041] Sandblasting: first use an aluminum cover plate to cover part or all of the sand-free area 2 with protective ink on the silk screen, and use a sandblasting machine with 6 to 8 nozzles to sandblast the frosted area 1 of the glass. The conveyor belt advances, the sandblasting liquid includes sand and water and the concentration of sand is 15-30wt%, and the sand is angular aluminum oxide; during the sandblasting process, the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com