A multi-grain disc grinding device

A disc type, multi-granularity technology, applied in the field of grinding processing, can solve the problems of high labor intensity, low grinding processing efficiency, not one-time completion, etc., to achieve strong automatic cleaning ability, good grinding effect, and negative impact. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

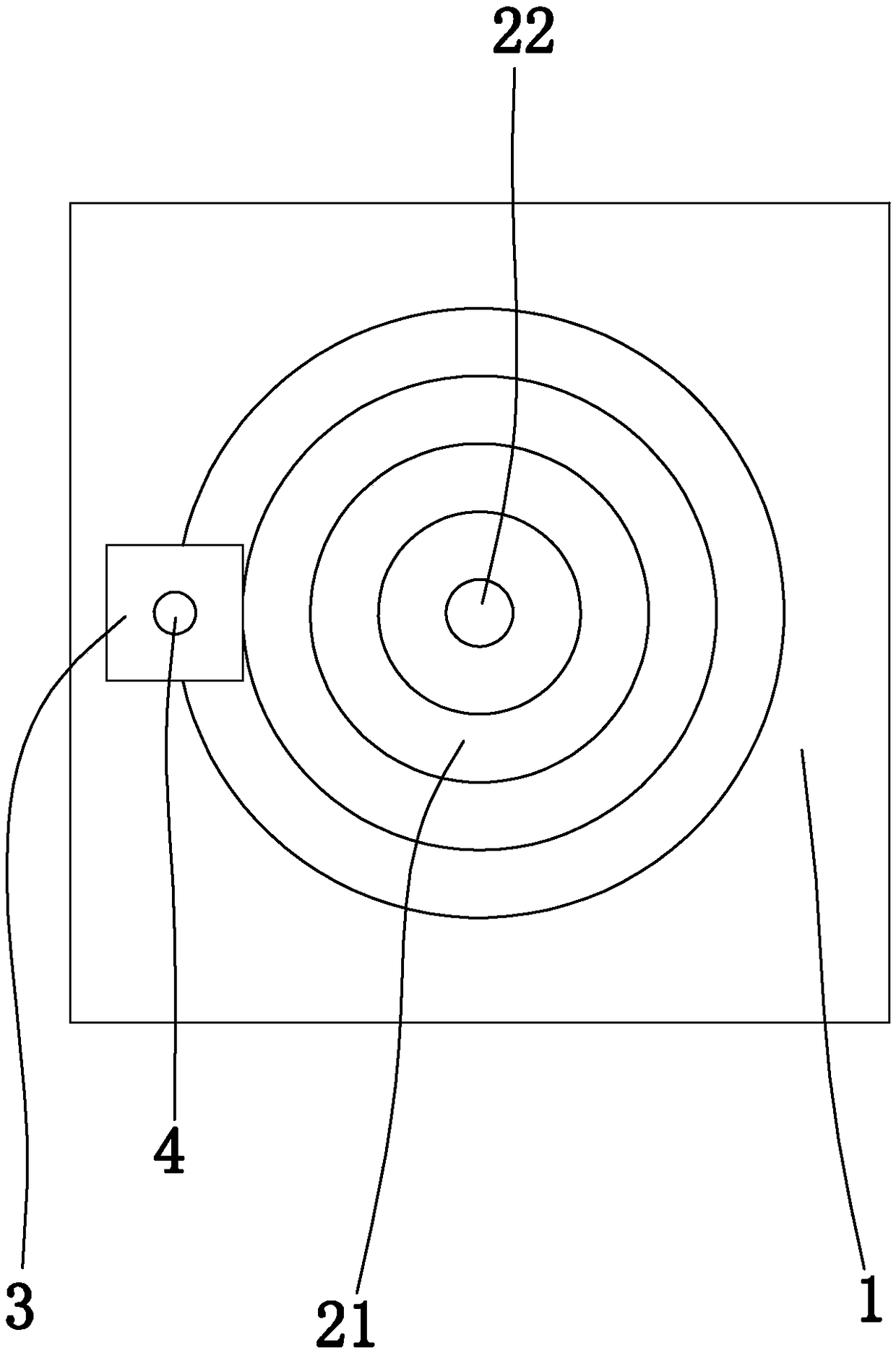

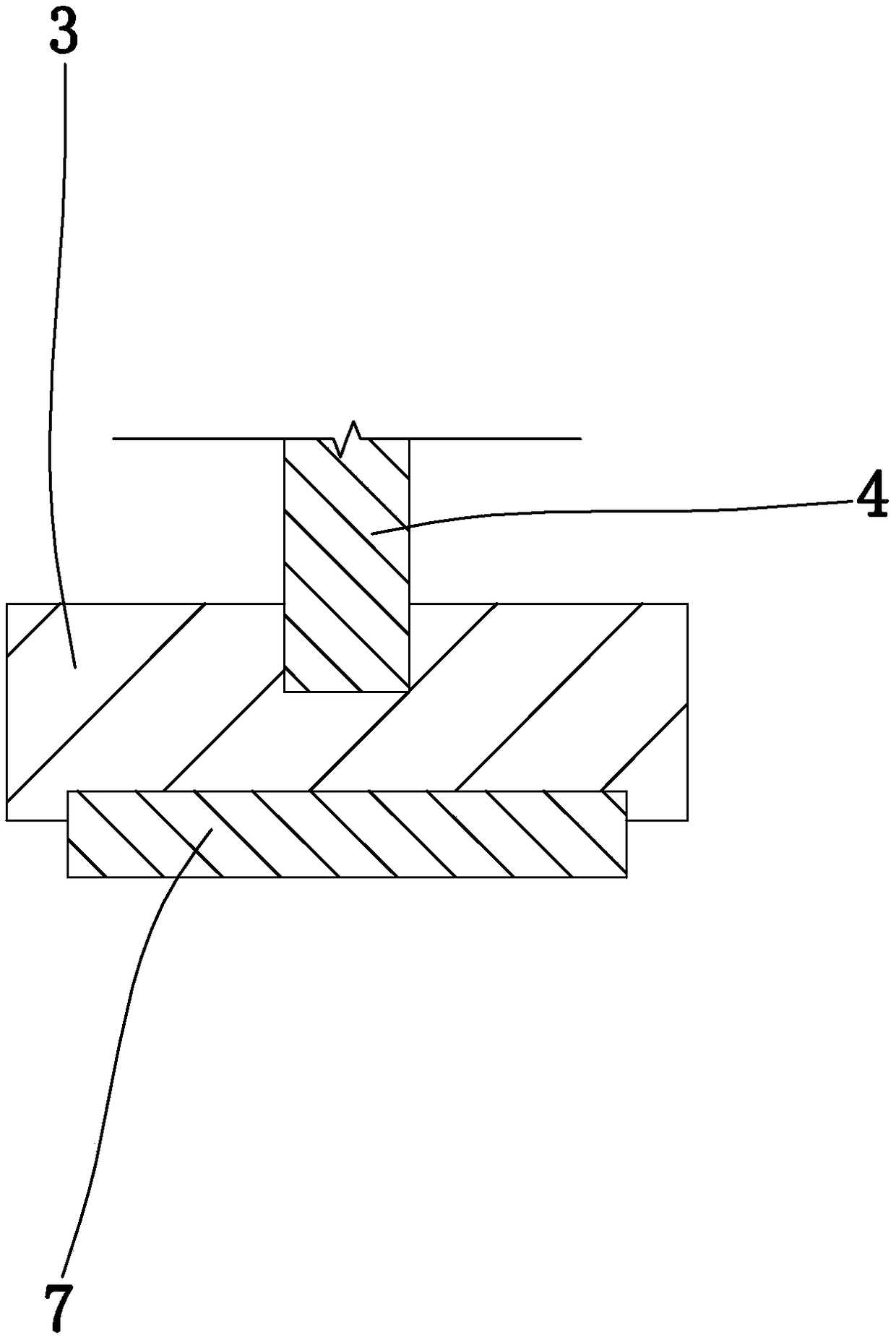

[0024] Embodiment 1: as Figure 1 to Figure 2 In the shown embodiment, a kind of multi-grain disc type grinding device comprises

[0025] The main frame 1, the main grinding table arranged on the main frame, the power motor for driving the main grinding table to rotate, and the gravity pressing block 3 for pressing the workpiece on the main grinding table, the bottom of the gravity pressing block is provided with a workpiece positioning groove;

[0026] The main grinding disc includes a base disc and a number of annular abrasive layers 21 coaxially arranged sequentially from the inside to the outside, the base disc is rotatably matched with the main frame, and the rotation axis of the base disc coincides with the axis of the base disc;

[0027] Each annular abrasive layer is arranged on the top surface of the base plate, and among two adjacent annular abrasive layers: the abrasive particle size of the annular abrasive layer with a small inner diameter is smaller than that of t...

Embodiment 2

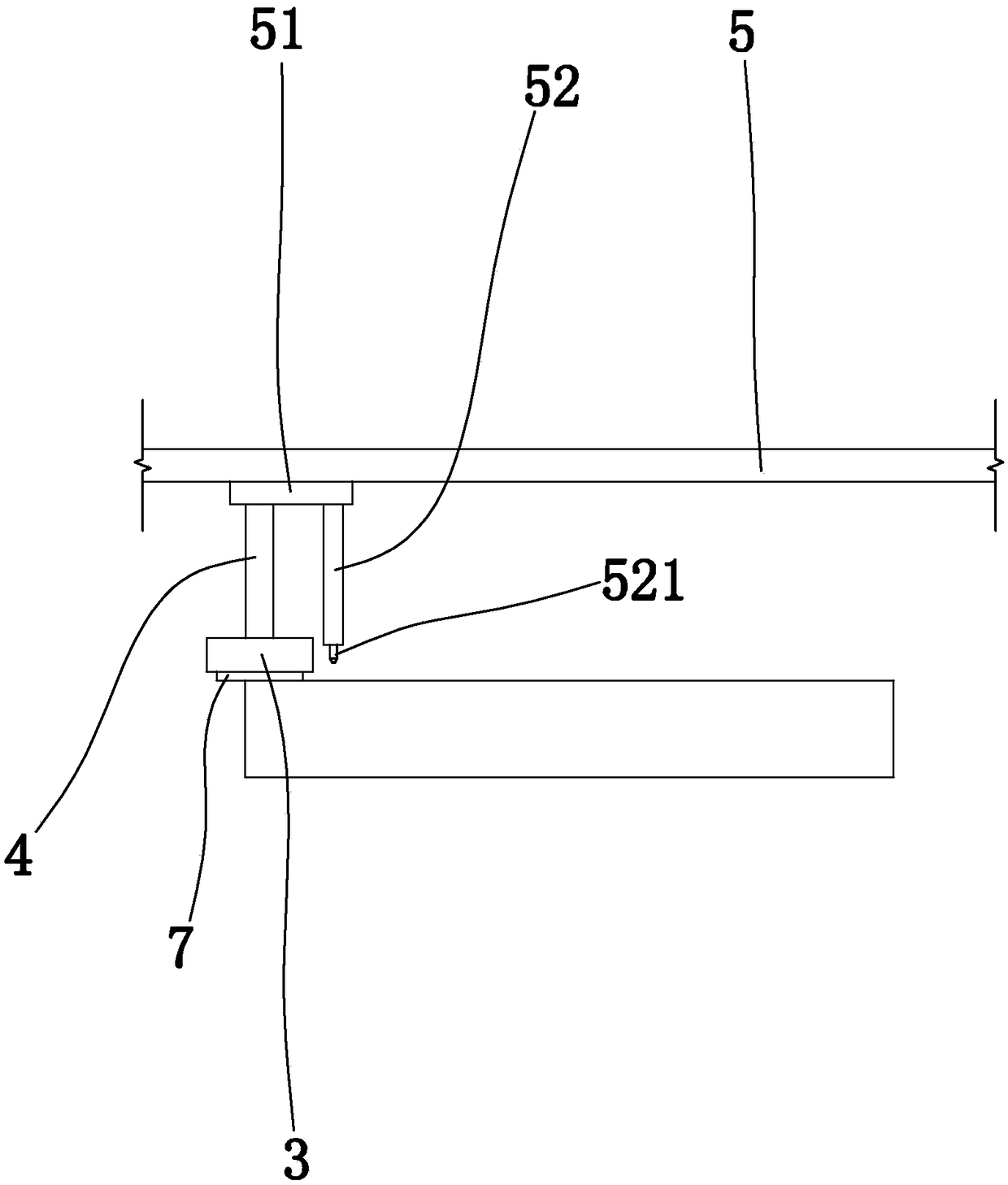

[0036] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as Figure 3 to Figure 4 As shown in , it also includes a transverse guide rail 5 relatively fixed to the main frame and a slide block 51 cooperating with the transverse guide rail, the slide block is fixed to the positioning shaft, and the sliding direction of the slide block is horizontal and perpendicular to the axis of the main grinding disc. The stability of the workpiece in the process of moving relative to the main grinding disc can be further ensured by using the horizontal guide rail and the slider. Here, electric slide rail type horizontal guide rail and slider can be used; external power devices (such as cylinders, electric reels) can also be used to drive the slider (and gravity pressure block) to move relative to the main grinding disc; manual operation can also be used. To drive the gravity pressing block to move relative to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com