A planetary continuous mill

A grinding machine and planetary technology, applied in the field of grinding processing, can solve the problems of high labor intensity, low grinding processing efficiency, time-consuming and labor-intensive, etc., and achieve the effects of strong automatic cleaning ability, excellent grinding effect and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

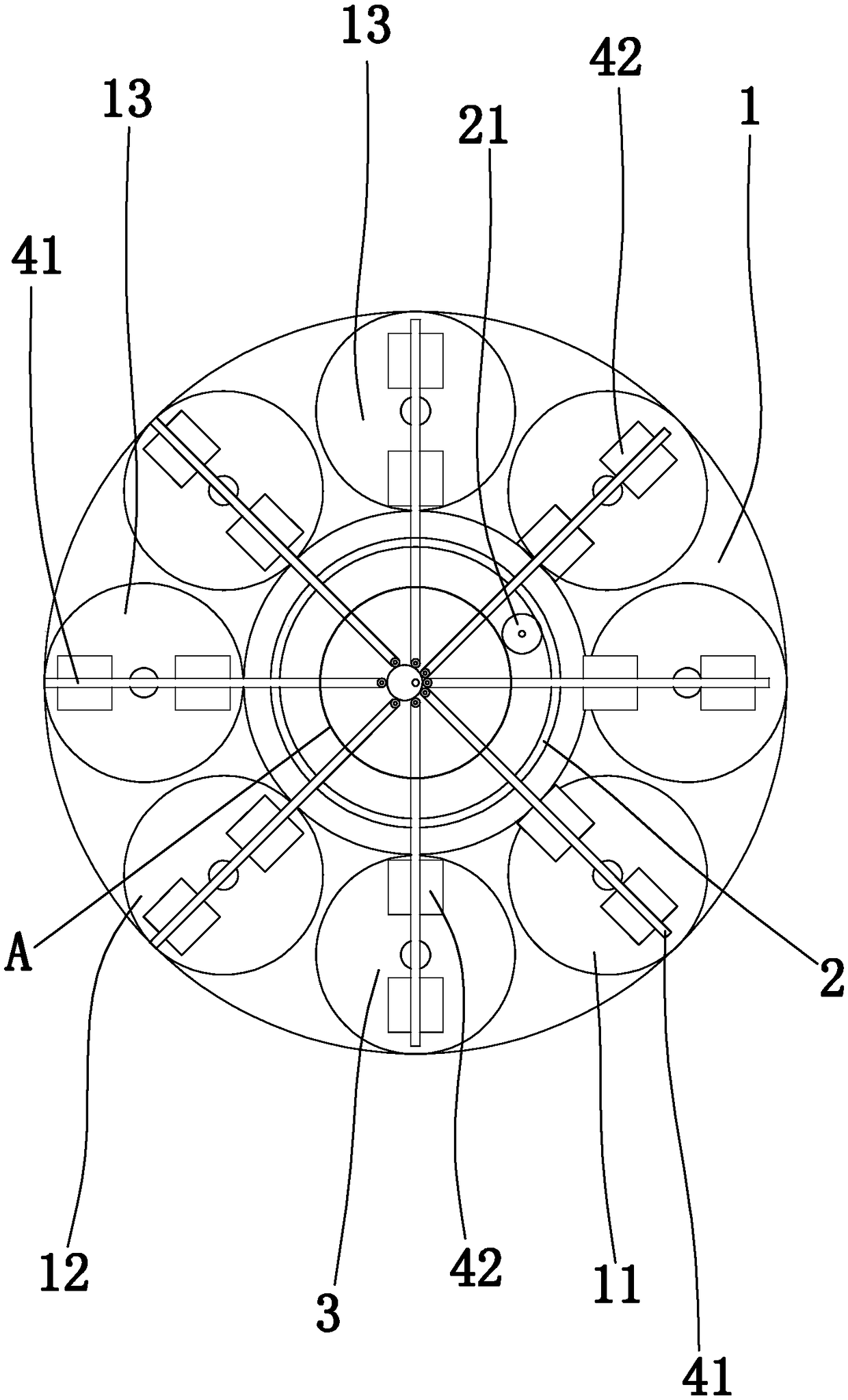

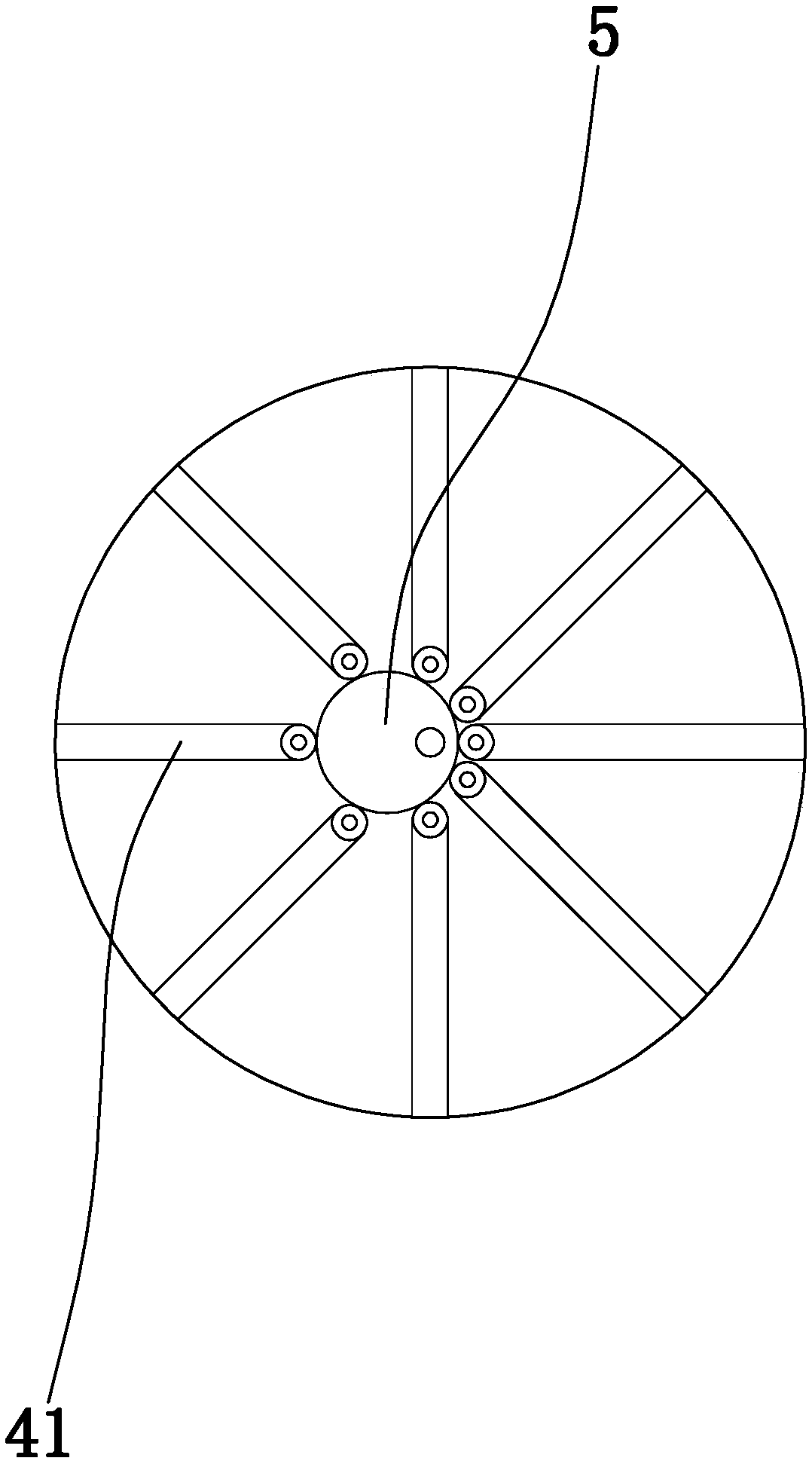

[0023] Embodiment 1: as Figure 1 to Figure 2 In the illustrated embodiment, a planetary continuous mill comprising

[0024] The main frame 1, the vacant station, the drive ring gear 2 and the main motor for driving the drive ring gear to rotate;

[0025] The main frame is provided with a starting mill 11, a terminal mill 12 and a number of intermediate mills 13, the vacant station includes a support table 3, the initial mill includes a starting mill, the terminal mill includes a terminal mill, and the middle mill The machine includes the middle grinding disc, the starting grinding disc, each intermediate grinding disc, the terminal grinding disc and the support table are distributed in sequence along the circumference of the driving ring gear;

[0026] The drive ring gear is rotatably connected to the main frame, the axis of the drive ring gear is vertical, and several workpiece positioning structures are arranged on the drive ring gear, and the workpiece positioning structu...

Embodiment 2

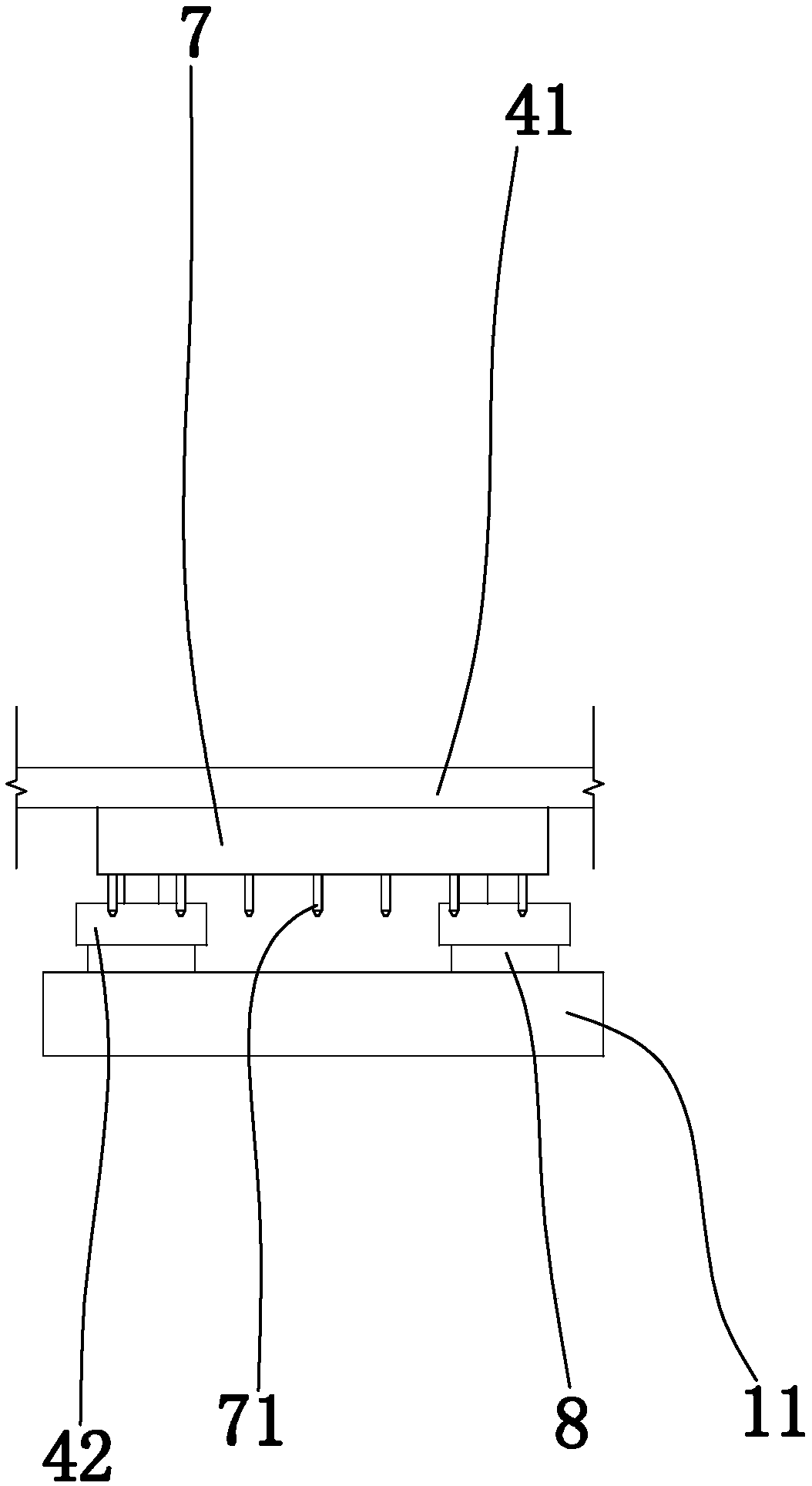

[0036] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as Figure 3 to Figure 4 As shown in , the main frame is provided with an air supply cylinder block 61, a fixed sliding seat 62 and a gear shaft 63 connected in rotation with the main frame, a driven gear is provided on the gear shaft, and a driving gear is provided on the output shaft of the main motor. Gear, the driving gear meshes with the driven gear, the gear shaft is provided with a starting plate 64 coaxially connected with the gear shaft, the starting plate is provided with an eccentric rod 65, and the air supply cylinder body is provided with a sliding seal for the air supply cylinder body. The air supply piston 611, the air supply piston divides the interior of the air supply cylinder body into an air supply chamber 61a and an adapting chamber 61b that communicates with the outside world, the air supply piston is provided with a pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com