Hydraulic tool and processing method for processing dual-arm planet carrier

A planet carrier and tooling technology, which is used in metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve the problems of high processing cost, complex production, and many labor, and achieve stable control of coaxiality and position, avoiding Clamping deformation or damage, the effect of avoiding clamping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to enable those skilled in the art to better understand the solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

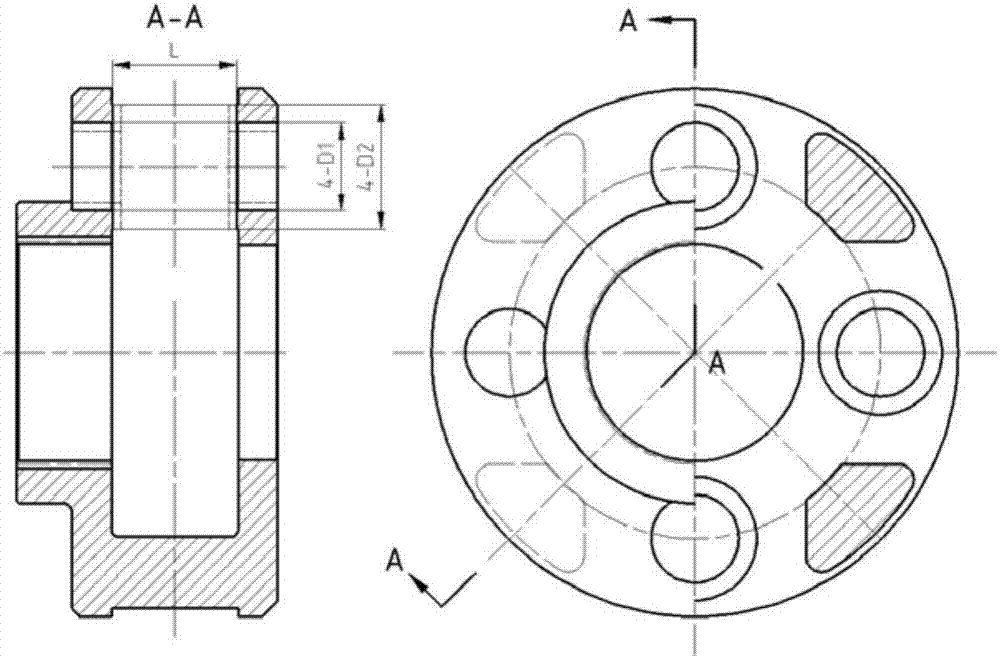

[0043] Hydraulic tooling for processing double-arm planet carrier 1, such as Figure 2-3 As shown, it includes tie rod press plate 3, parts press plate 2, tie rod 4, support seat 6, tooling base plate 7 and hydraulic cylinder 8; one end of tie rod 4 runs through the center hole of parts press plate 2 and is fixedly connected with the center of tie rod press plate 3, and the parts press plate The size of the central hole of 2 is larger than the cross-sectional size of the tie rod 4, and the other end of the tie rod 4 is fixedly connected with the piston of the hydraulic cylinder 8. The shape of the part pressure plate 2 is star-shaped, and each star-shaped corner of the part pressure plate 2 is fixed with a pressure bolt. Column 5. When it is used to install th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com