The spindle of the machining center does not stop rotating, and there is an automatic tool changer for manipulators

A machining center and automatic tool change technology, applied in metal processing machinery parts, positioning devices, metal processing equipment, etc., can solve the problem of time waste, reduce production costs, have broad application prospects, and save tool change time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The automatic tool changer with manipulator for non-stop rotation of the spindle of the machining center proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that the drawings are all in very simplified form and use imprecise ratios, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

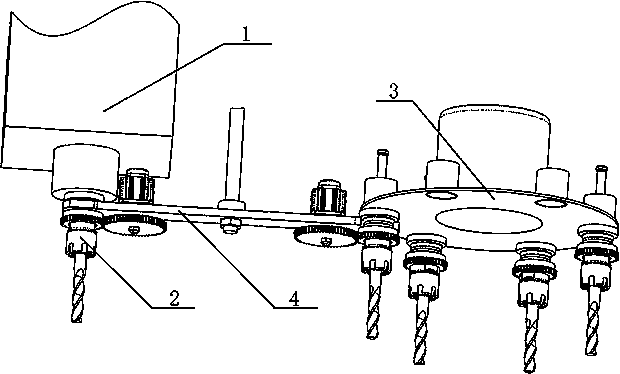

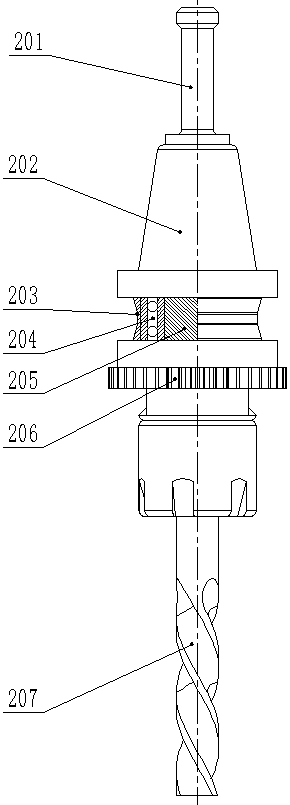

[0043]The spindle of the machining center rotates continuously and has an automatic tool changing device with a manipulator, which is characterized in that it includes a main shaft 1, a tool handle 2, a tool magazine 3, a tool changing manipulator 4 and a numerical control system (not shown).

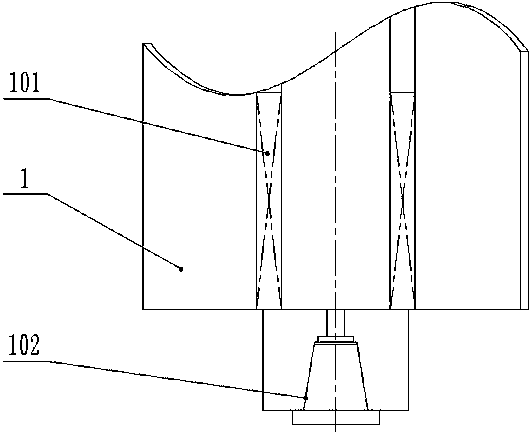

[0044] The main shaft 1 includes an electric main shaft rotation driving device 101 in the middle, an inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com