Method for preparing external paste for treating arthralgia

A joint pain and plaster technology, which is applied in the field of preparation of external plasters, can solve the problems of low volatility of active ingredients, long-lasting effects of medicines, poor efficacy of medicines, and volatilization of active ingredients in plasters, etc., to achieve good swelling and emulsification effects, and volatile Low toxicity, good long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

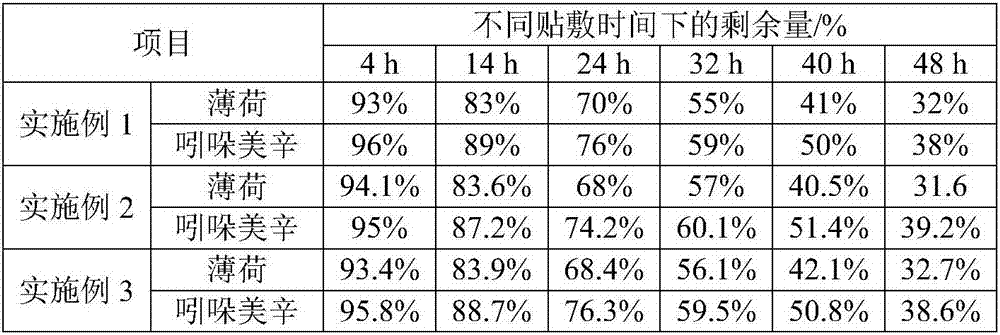

Examples

Embodiment 1

[0030] A preparation method for an external plaster for treating arthralgia, comprising the following steps:

[0031] (1) Rubber rolling: the raw rubber is removed from the film and cut into 10cm long rubber strips, put into a rubber mixing machine and rolled to obtain a rubber sheet, so that both sides of the rubber sheet form a grid pattern, and the thickness of the rubber sheet is 3mm;

[0032](2) Swelling rubber: place the rubber flakes in a mixer and add gasoline solvent, stir regularly and soak in ultrasonic for later use, wherein the gasoline solvent used is mixed with No. 120 gasoline and ethanol, and the volume percentage of No. 120 gasoline is 80%. The weight ratio of rubber flakes to gasoline solvent is 1:4.2, the stirring and soaking process is: stir for 2 minutes every 3 hours, and then continue to soak for more than 24 hours until the rubber flakes are fully swollen and softened, preferably 25 hours, and the stirring speed is 30r / min , the soaking temperature is ...

Embodiment 2

[0041] A preparation method for an external plaster for treating arthralgia, comprising the following steps:

[0042] (1) Rubber rolling: the raw rubber is removed from the film and cut into 15cm long rubber strips, put into a rubber mixing machine and rolled to obtain a rubber sheet, so that both sides of the rubber sheet form a grid pattern, and the thickness of the rubber sheet is 4mm;

[0043] (2) Swelling rubber: the rubber sheet is placed in a mixer and added gasoline solvent, regularly stirred and ultrasonically soaked for later use, wherein the gasoline solvent used is mixed with No. 120 gasoline and ethanol, and the volume percentage of No. 120 gasoline is 85%. The weight ratio of rubber flakes to gasoline solvent is 1:5.5. The stirring and soaking process is: stir for 2 minutes every 3 hours, and then continue to soak for more than 24 hours until the rubber flakes are fully swollen and softened, preferably 27 hours, and the stirring speed is 35r / min , the soaking tem...

Embodiment 3

[0052] A preparation method for an external plaster for treating arthralgia, comprising the following steps:

[0053] (1) Rubber rolling: the raw rubber is removed from the film and cut into 10cm long rubber strips, put into a rubber mixing machine and rolled to obtain a rubber sheet, so that both sides of the rubber sheet form a grid pattern, and the thickness of the rubber sheet is 5mm;

[0054] (2) Swelling rubber: place the rubber flakes in a mixer and add gasoline solvent, stir regularly and soak in ultrasonic for later use, wherein the gasoline solvent used is mixed with No. 120 gasoline and ethanol, and the volume percentage of No. 120 gasoline is 90%. The weight ratio of rubber flakes to gasoline solvent is 1:4.2. The stirring and soaking process is: stir for 2 minutes every 3 hours, and then continue to soak for more than 24 hours until the rubber flakes are fully swollen and softened. The stirring speed is 40r / min, and the soaking temperature is 30°C, ultrasonic assi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com