System and method for integrity testing of flexible containers

Integrity, container technology, applied in the field of systems and methods for testing the integrity of flexible containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] As described, conventional pressure-based integrity testing has limitations, especially as the volume of the flexible container under test becomes large, such as in excess of 200 liters.

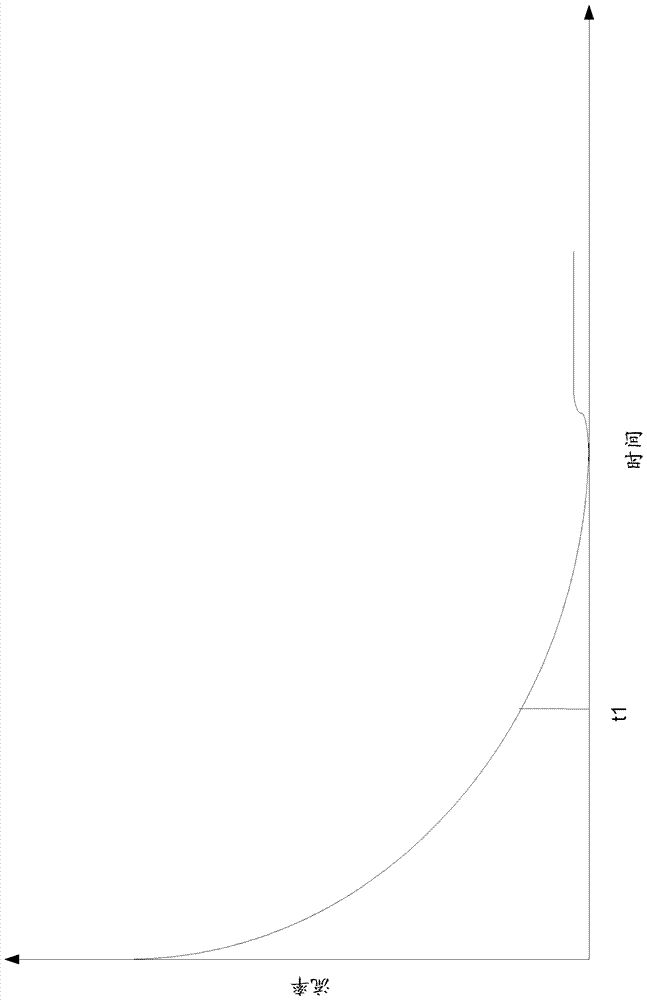

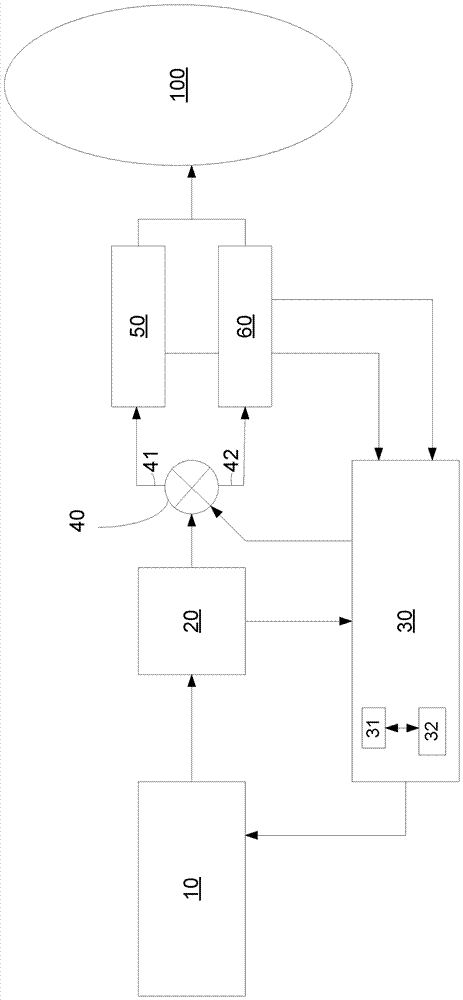

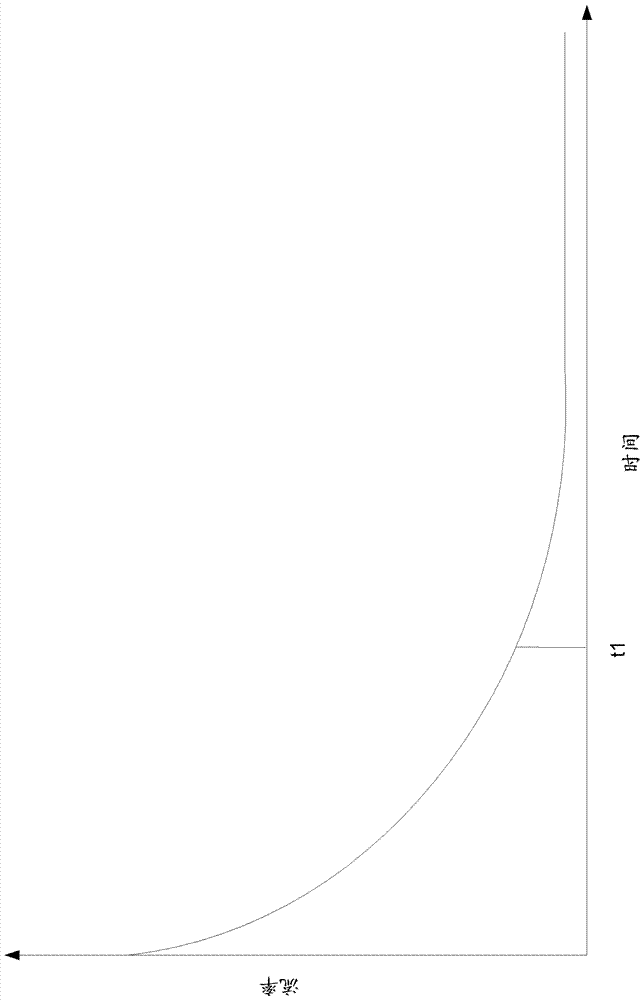

[0023] Rather than using pressure changes to determine integrity, the present systems and methods use flow rate to determine. figure 1 A system is shown that can be used to fill flexible containers and also to test their integrity.

[0024] In this embodiment there is a supply of air or another suitable fluid. Typically, the fluid used will be in gaseous form. Fluid supply 10 may be a source of compressed air or may be air conveyed through a blower, fan or other device. In various embodiments, the fluid supply 10 provides a fluid, such as air, at a variable pressure above the ambient pressure.

[0025] Fluid supply 10 communicates with sensor 20 . This sensor 20 may be a digital pressure sensor which measures the pressure of the incoming fluid from the fluid supply 10 . Controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com