Method for measuring concentration of NaSCN solution through conductivity

A solution concentration and conductivity measurement technology, applied in the field of analysis and testing, can solve the problems of increased sample cost, time-consuming, uneconomical, etc., and achieve the effect of reliable data, small process error and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

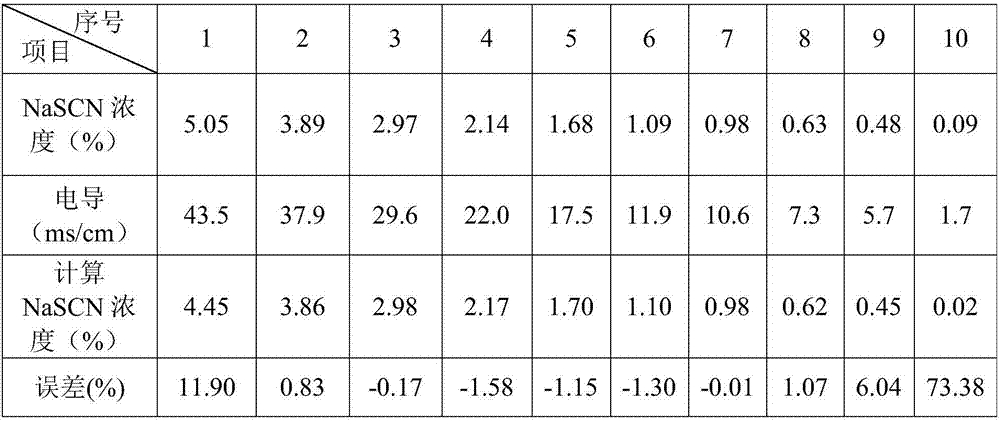

[0063] Embodiment 1~6 (low concentration NaSCN solution)

[0064] Six NaSCN solution samples with different concentrations were randomly taken, and the corresponding concentrations were calculated after measuring the conductance with a conductivity meter.

[0065] Steps include:

[0066] 1) measure the specific gravity of NaSCN solution;

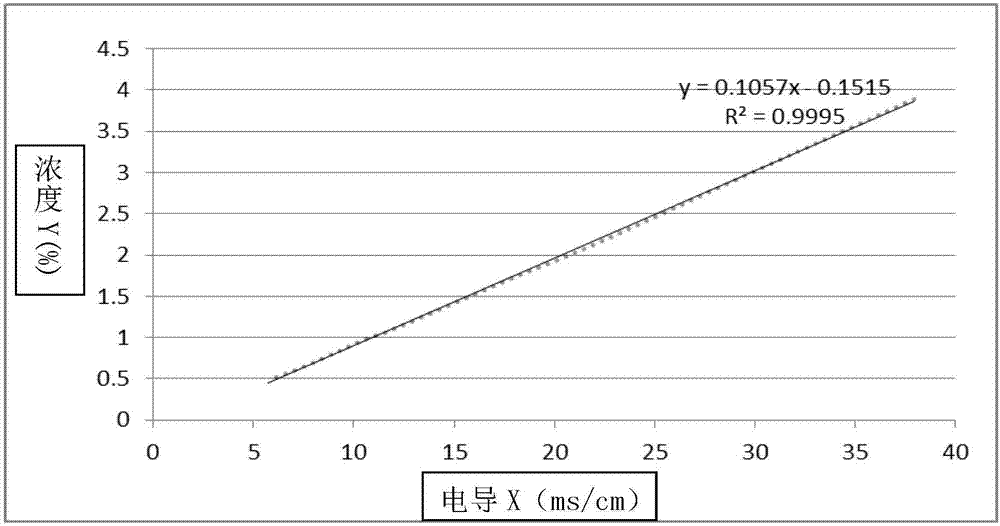

[0067] 2) Calculate the concentration of NaSCN solution by formula Y=0.1057X-0.1515;

[0068] Wherein, X represents the proportion of NaSCN solution, and Y represents the concentration of NaSCN solution;

[0069] 3) according to the concentration of the NaSCN that step 2) obtains;

[0070] 4) Perform potentiometric titration on the same sample to obtain an accurate concentration, compare the measured concentration with the calculated concentration and calculate the error. See Table 1 for process data.

[0071] Table 1

[0072]

[0073] Practice has proved that the concentration value of NaSCN solution in a specific condition range can...

Embodiment 4~6

[0074] Embodiment 4~6 (concentration of Ppm level NaSCN solution)

[0075] Six NaSCN solution samples with different concentrations were randomly taken at the on-line conductivity meter at the production site, and the corresponding concentrations were calculated after recording the on-line conductivity value at the same time.

[0076] Steps include:

[0077] 1) measure the specific gravity of NaSCN solution;

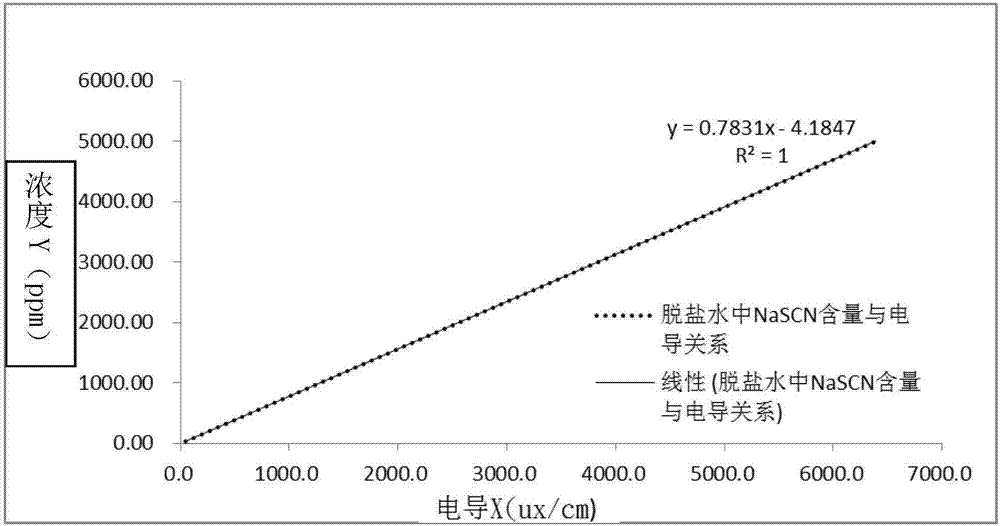

[0078] 2) Calculate the concentration of NaSCN solution by formula Y=0.7831X-4.1847;

[0079] Wherein, X represents the proportion of NaSCN solution, and Y represents the concentration of NaSCN solution;

[0080] 3) according to the concentration of the NaSCN that step 2) obtains;

[0081] 4) Perform potentiometric titration on the same sample to obtain an accurate concentration, compare the measured concentration with the calculated concentration and calculate the error. See Table 2 for process data.

[0082] Table 2

[0083]

[0084] Practice has proved that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com