Supercritical carbon dioxide generalized generality Carnot cycle system

A carbon dioxide and circulation system technology, applied in steam engine installations, machines/engines, mechanical equipment, etc., can solve the problems of increasing the average endothermic temperature, increasing the cost of the unit, and widening the endothermic temperature range, so as to improve the average endothermic temperature, The effect of improving heat exchange efficiency and reducing inlet temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

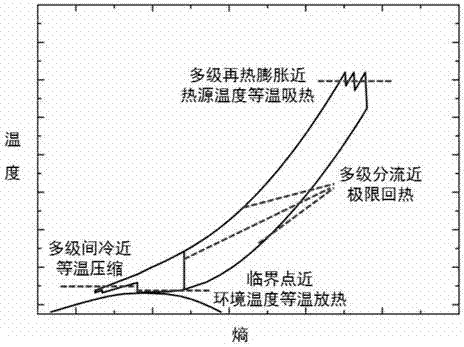

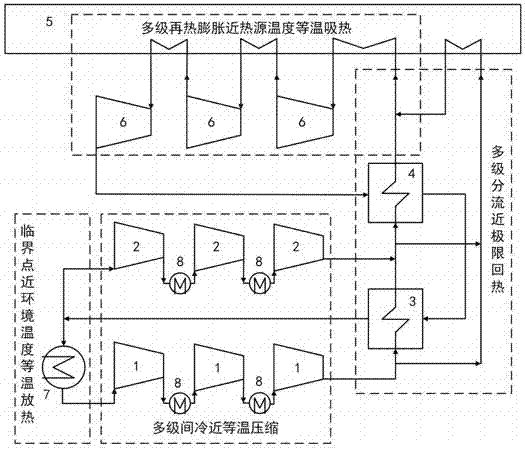

[0026] see figure 1 , 2. The present invention includes a multi-stage intercooling near-isothermal compression system, a multi-stage split flow near-limit recuperation system, a multi-stage reheat expansion near-high-temperature heat source temperature isothermal endothermic system, and a critical point near-ambient temperature isothermal exothermic system;

[0027] The multi-stage intercooled near-isothermal compression system includes end-to-end multi-stage main compressors 1 and multi-stage re-compressors 2, and intercoolers are respectively installed between adjacent main compressors 1 and adjacent re-compressors 2. device 8;

[0028] The multi-stage split flow near-limit recuperation system includes a low-temperature regenerator 3 and a high-temperature regenerator 4;

[0029] The multi-stage reheat expansion near-high-temperature heat source temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com