A kind of polymerizable fluorescent dichroic dye and its preparation method and application

A dichroic dye and fluorescence technology, applied in luminescent materials, organic dyes, azo dyes, etc., can solve the problem of low light transmission efficiency, and achieve the effects of high quantum efficiency, high polarization fluorescence, and high dichroic ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

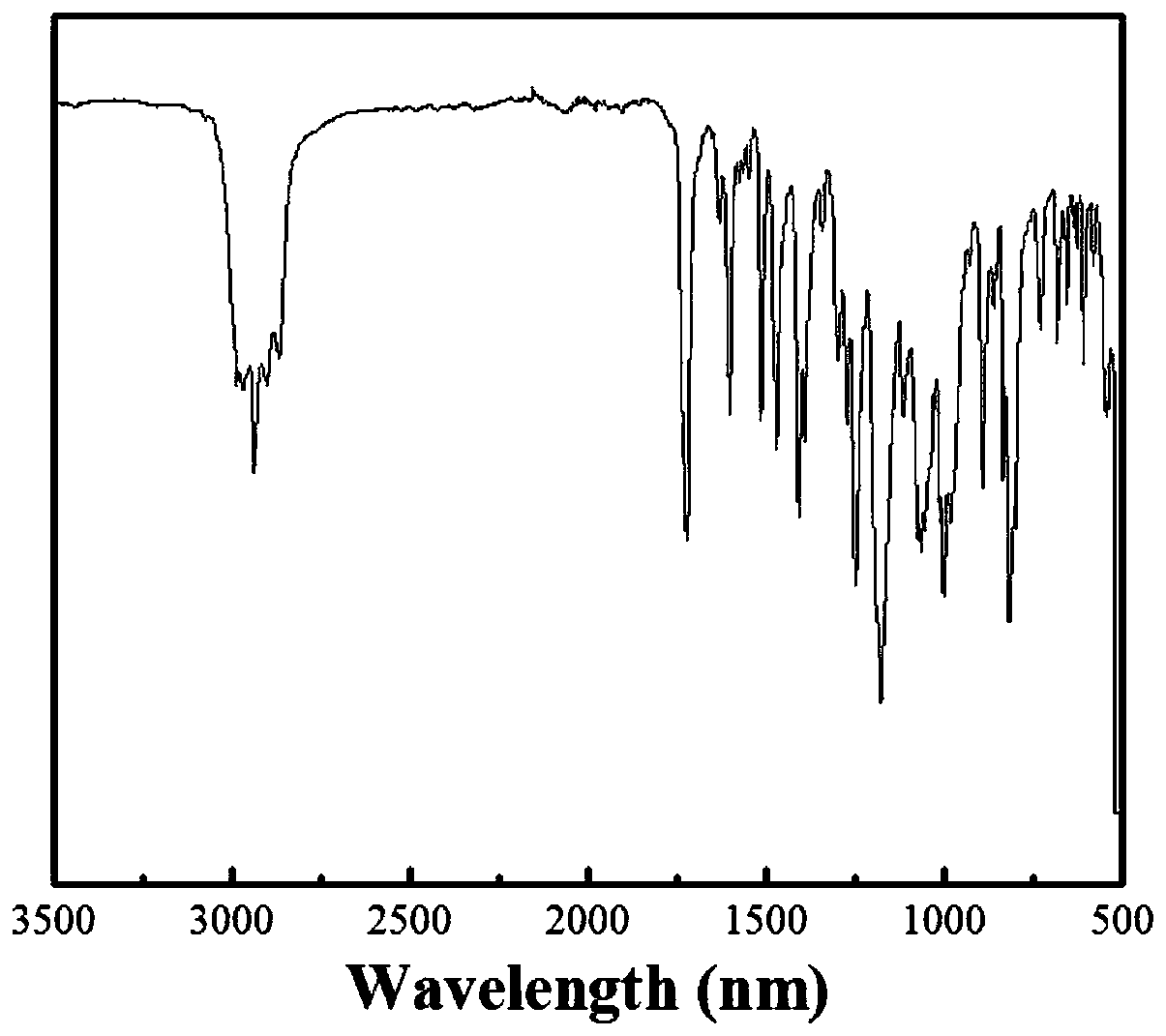

[0036] The preparation of dichroic dye, synthetic route is:

[0037]

[0038] Concrete synthetic steps are as follows:

[0039] 1.1 Preparation of intermediate 1

[0040] Weigh 11.7g of 4,7-dibromo-2,1,3-benzothiadiazole and 15.2g of p-methoxyphenylboronic acid, dissolve in 210mL of 1,4-dioxane, protect under nitrogen environment, and weigh again Take 16.5g K 2 CO 3 Make a 2M aqueous solution and add it to the flask for stirring, then add 3.5g Pd(PPh 3 ) 4 , control the reaction temperature at 103-105 ° C, reflux for 24 hours, cool to room temperature after the reaction, and obtain intermediate 1 (9.5 g) after suction filtration and vacuum drying, with a yield of 68%;

[0041] 1.2 Preparation of Intermediate 2

[0042] Weigh 4.6g of intermediate 1 prepared in step (1), add 100mL of hydrobromic acetic acid solution, then add 4.6g of tetra-n-butylammonium bromide, control the reaction temperature at 70°C, reflux for 24h, and cool to At room temperature, the solid was f...

Embodiment 2

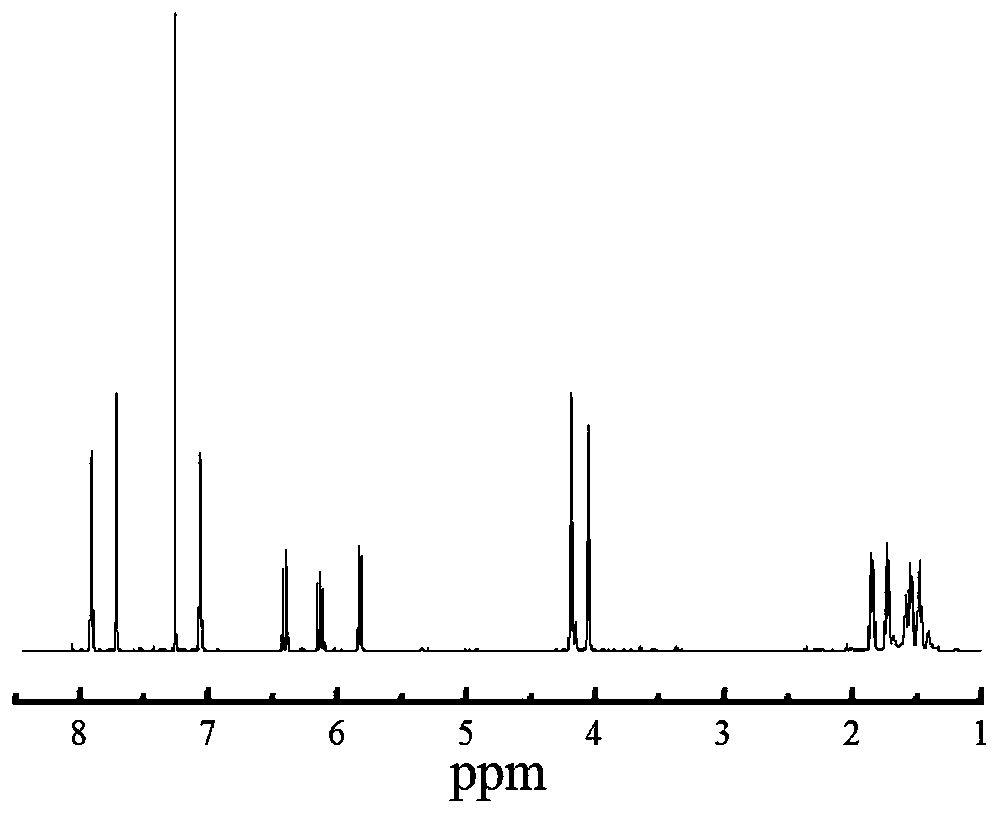

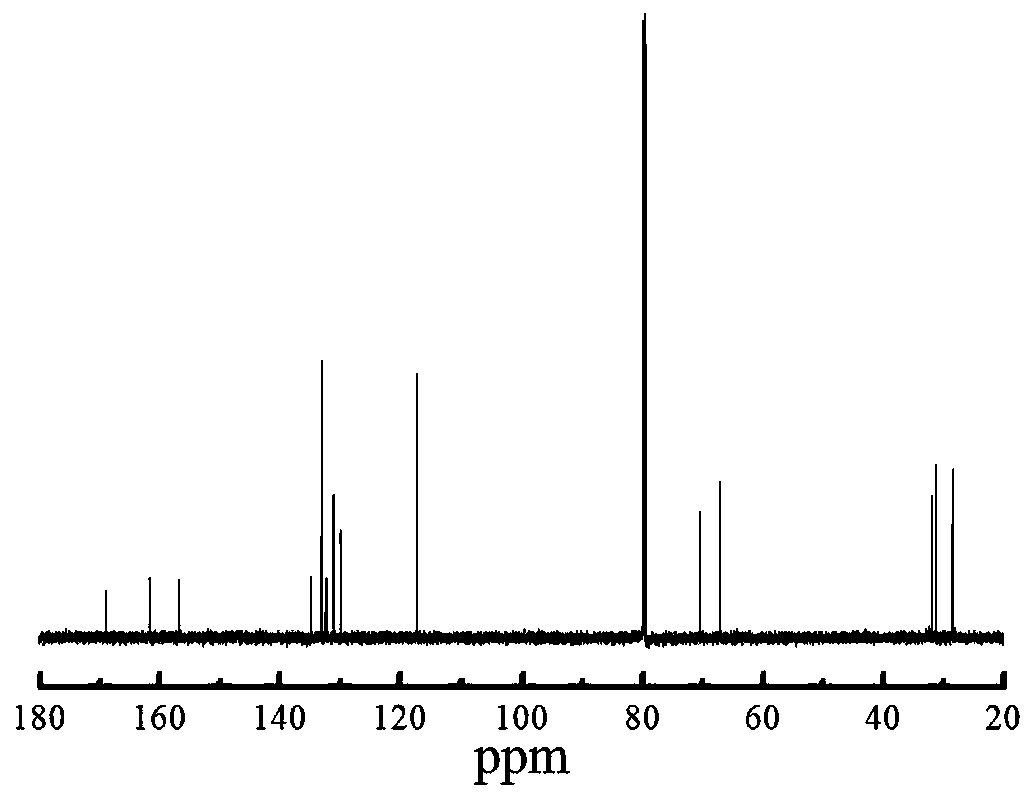

[0048] Quantum Efficiency Test of Dichroic Dyes

[0049] Use a high-precision balance to accurately weigh 0.00314g of dichroic dye, add 5mL of DMF to make a concentration of 10 -3 mol / L mother solution, use a pipette gun to accurately draw 5 μL of the mother solution and place it in a cuvette, then add 5 mL of DMF to make a concentration of 10 -6 mol / L dilution. Put the cuvette into the integrating sphere, and measure the quantum efficiency of the dichroic dye solution with a fluorescence spectrometer to be 0.82. The dichroic dye powder is placed on an integrating sphere stage, and the quantum efficiency of the dichroic dye powder is measured by a fluorescence spectrometer to be 0.85.

Embodiment 3

[0051] Calculation of Molecular Long Axis and Dipole Moment Direction of Dichroic Dye

[0052] Use the Avogadro constant software to draw the three-dimensional configuration diagram of the dichroic dye molecule and optimize it. The optimized mol file is imported into the GaussView 09 software, and the B3YP / 6-31G unit is used for simulation calculation. The calculated results It is shown that the molecular long axis of the dichroic dye molecule is parallel to the direction of the dipole moment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com