Method and apparatus for rectifying purification of battery grade dimethyl carbonate

A technology of dimethyl carbonate and a purification method, which is applied in the field of battery-grade dimethyl carbonate rectification and purification, can solve the problems of high production energy consumption and large equipment investment, and achieves reduction of equipment investment, meeting separation requirements, and reducing equipment investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Purification of 15,000 tons / year of dimethyl carbonate, wherein the feed composition and related parameters are as follows:

[0055] Crude dimethyl carbonate feed composition: methanol 1%, ethanol 1%, water 1%, dimethyl carbonate 95%, ethyl methyl carbonate 1%, diethyl carbonate 1%. The feed flow rate is 2 tons / hour.

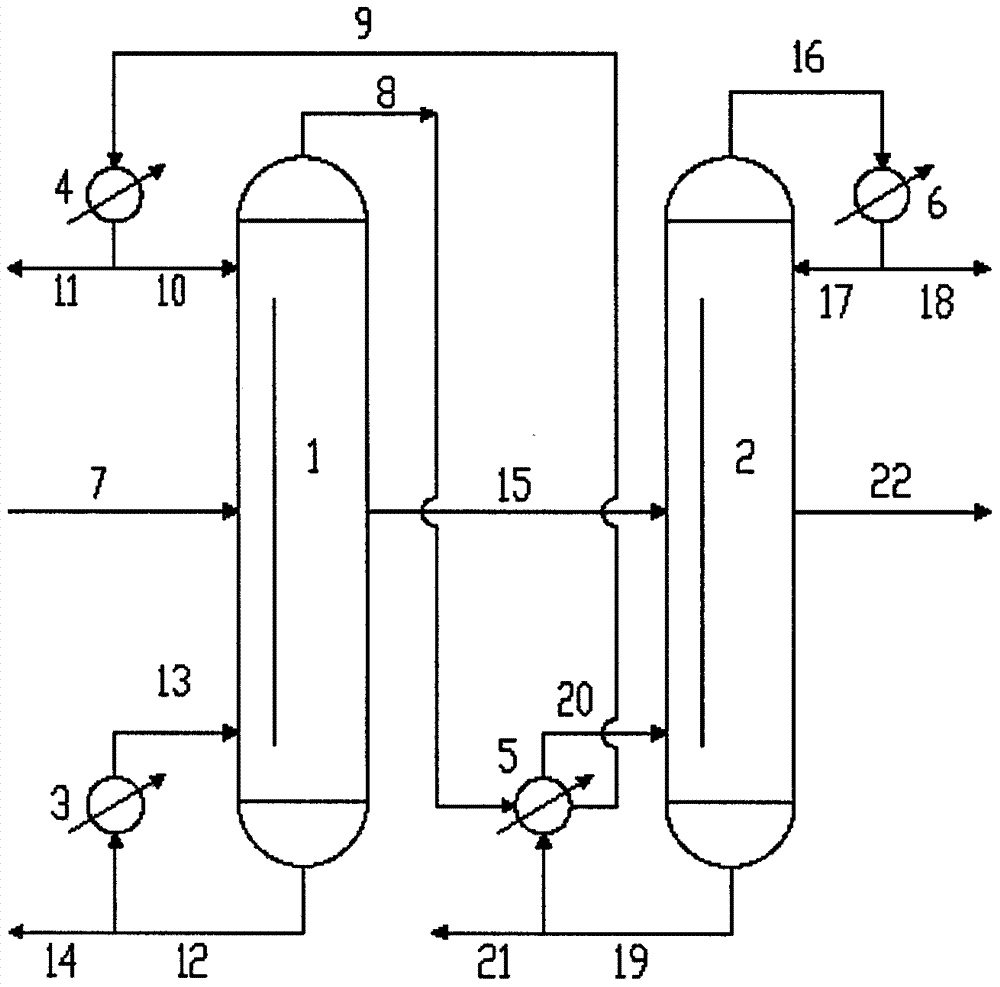

[0056] Atmospheric pressure dividing wall rectifying tower top pressure is normal pressure, tower top temperature is 66.6 ℃, reflux / feed amount (L / F)=5.1; Low pressure dividing wall rectifying tower tower top pressure is 10kPa, tower top temperature is 25.1 °C, reflux / feed (L / F) = 8.2.

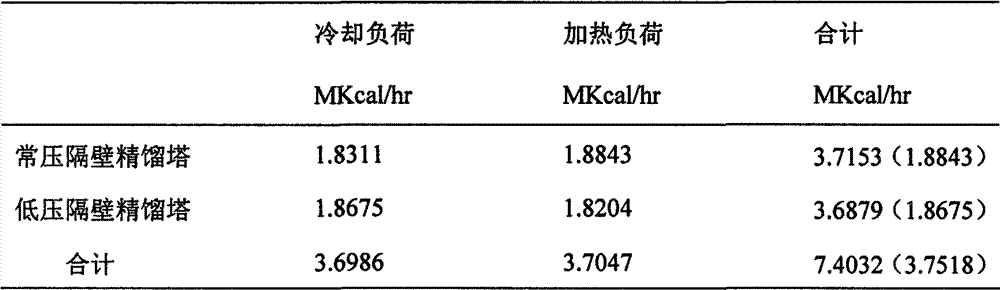

[0057] The heat load of the atmospheric pressure dividing wall rectification tower and the low pressure dividing wall rectification tower used for the production of battery-grade dimethyl carbonate is shown in Table 1. Since the separation process utilizes differential pressure thermal coupling technology, the atmospheric pressure dividing wall rectification tower The c...

Embodiment 2

[0062] Purification of 15,000 tons / year of dimethyl carbonate, wherein the feed composition and related parameters are as follows:

[0063] Crude dimethyl carbonate feed composition: methanol 0.8%, ethanol 1.2%, water 1.1%, dimethyl carbonate 95%, ethyl methyl carbonate 1.4%, diethyl carbonate 0.5%. The feed flow rate is 2 tons / hour.

[0064] Atmospheric pressure dividing wall rectifying tower top pressure is normal pressure, tower top temperature is 67.7 ℃, reflux / feed amount (L / F)=5.3; Low pressure dividing wall rectifying tower top pressure position is 15kPa, tower top temperature is 32.9 °C, reflux / feed (L / F) = 9.0.

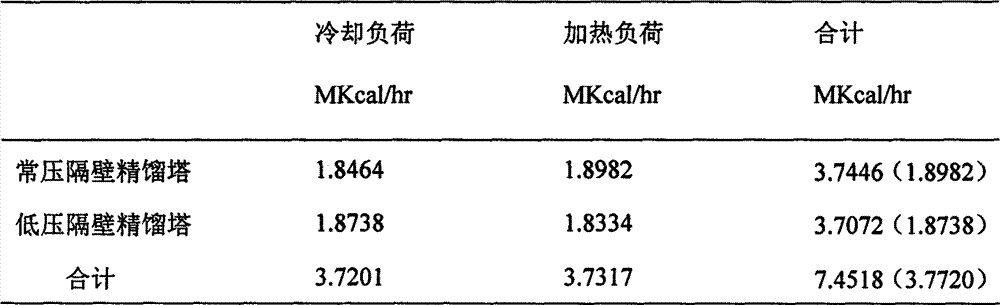

[0065] The heat load of the atmospheric pressure dividing wall rectifying tower and the low pressure dividing wall rectifying tower used for the production of battery-grade dimethyl carbonate is shown in Table 2. Since this separation process utilizes differential pressure thermal coupling technology, the atmospheric pressure dividing wall rectifying tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com