Technique for preparing MIBK (methyl isobutyl ketone) from acetone with liquid-phase one-step process

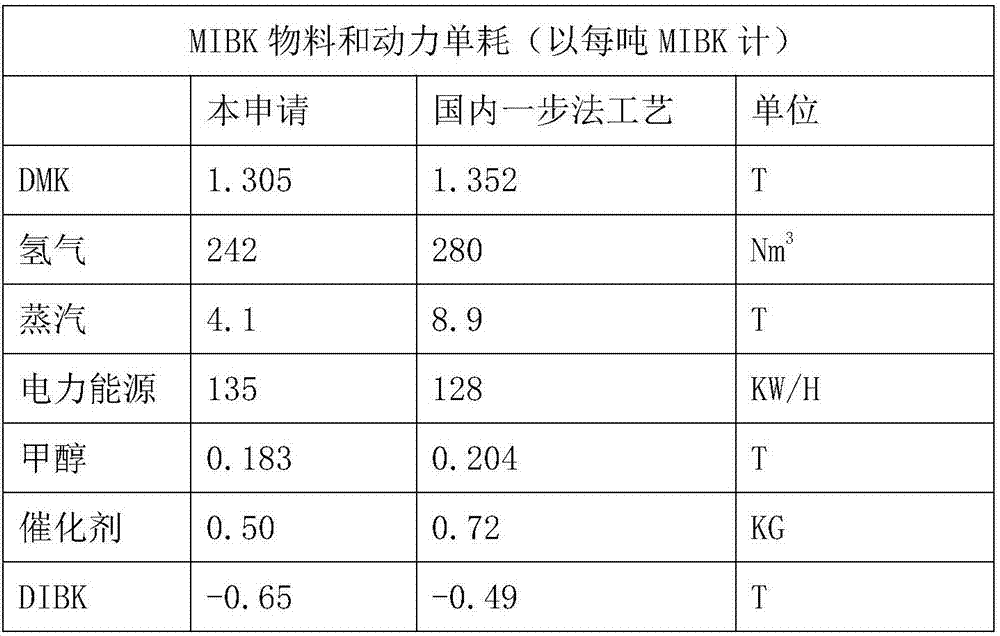

A technology of methyl isobutyl ketone and a process method, which is applied in the preparation of carbon-based compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of high palladium content, DIBK does not fully recover economic costs, etc., and achieves a process flow. The effect of short, high yield, high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

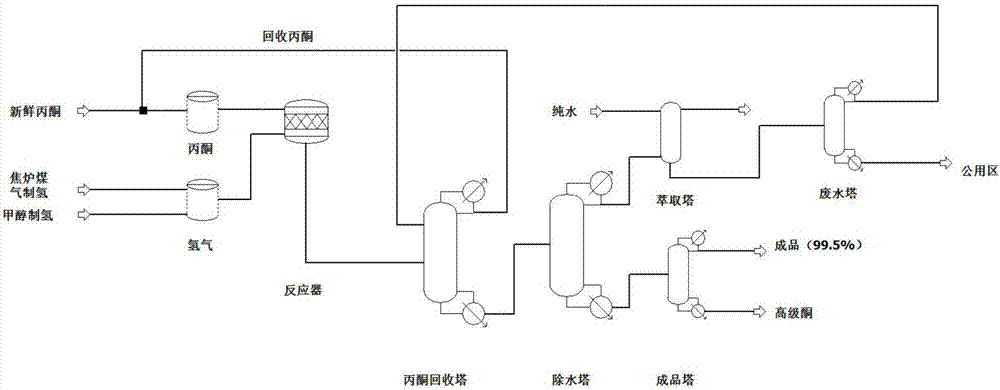

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiments. The protection scope of the present invention is not limited to the embodiments, and all technical solutions that belong to the idea of the present invention belong to the protection scope of the present invention. It should be pointed out that for those skilled in the art, some improvements without departing from the principle of the present invention should also be regarded as the protection scope of the present invention.

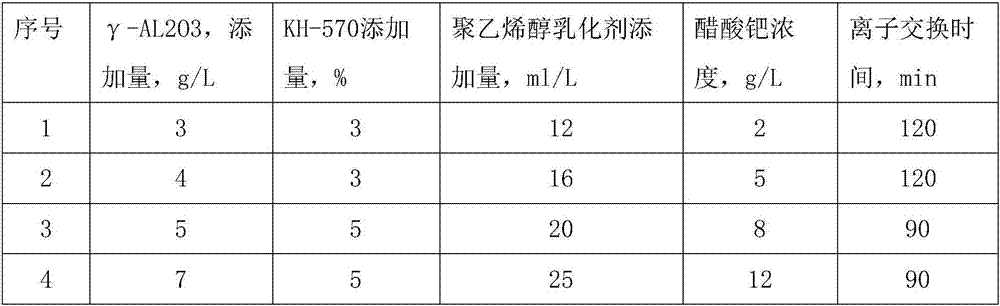

[0024] The steps of preparing a palladium-loaded cationic acid resin catalyst are as follows: First, add γ-AL2O3 into an aqueous solution of ethanol (dispersion) and carry out ultrasonic dispersion, so that the surface of commercially available γ-AL2O3 cannot avoid the elution and removal of residual impurities. After the γ-AL2O3 is gradually deposited, the upper layer solution is removed. Next, ethanol, acetic acid accounting for 20% of the mass of γ-AL2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com