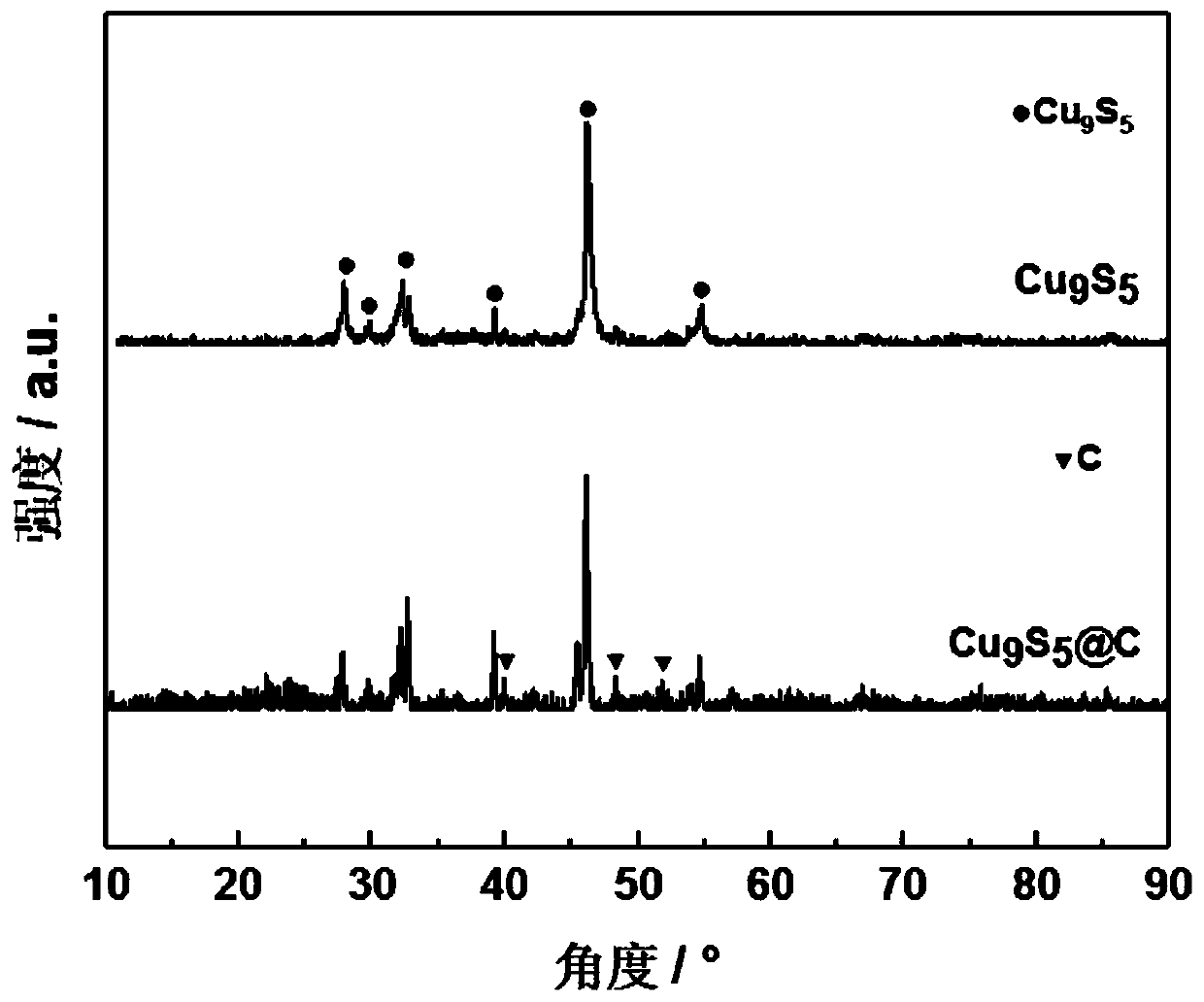

cu for battery negative 9 the s 5 Preparation method of @c nanocomposite material

A nano-composite material, battery negative electrode technology, applied in the field of electrochemistry, can solve problems such as low specific capacity, inability to meet the needs of high-capacity lithium-ion batteries, lithium dendrite safety issues, etc., to achieve high specific surface area, increase conductivity, improve performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

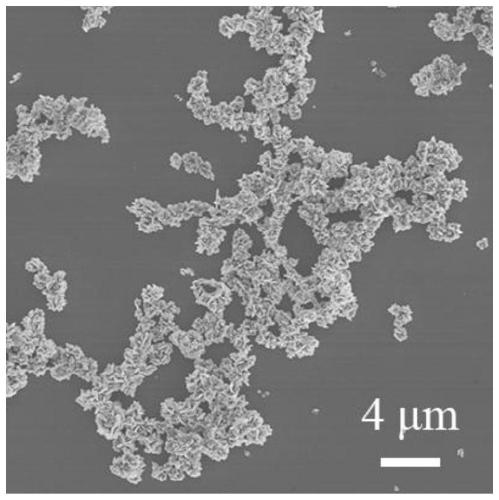

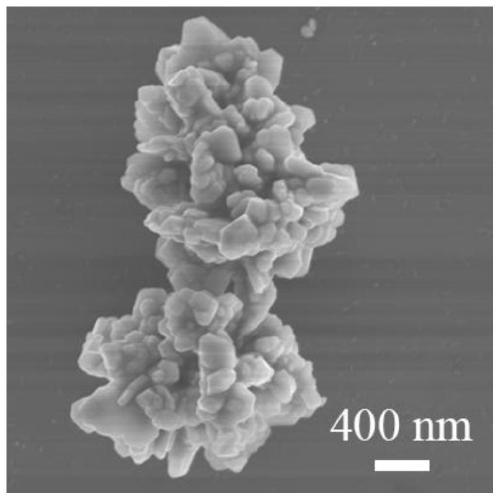

[0035] (1)Cu 9 S 5 Preparation: Weigh 67.32mg of sulfur powder in a container, add 3ml of 25% ammonia water and 15ml of absolute ethanol, stir evenly to obtain solution 1; weigh 139.76mg of copper acetate in another container, add 20mL Dehydrated ethanol, stirred evenly, to obtain solution 2; Add solution 1 dropwise to solution 2, stir evenly, to obtain solution 3; Transfer the above solution 3 to a hydrothermal reaction kettle, react at 160 ° C for 8 hours, and naturally Cool to obtain copper sulfide precipitate, centrifuge, wash and dry, and anneal the dried copper sulfide at 400°C for 2 hours in a nitrogen-protected environment to obtain Cu 9 S 5 Material;

[0036] (2) Glucose coated by hydrothermal method: take 100g Cu 9 S 5 Material, add 30mL deionized water, add 1g glucose after proper ultrasonic stirring, continue to stir, transfer to a hydrothermal reaction kettle, heat at 180°C for 3 hours, and obtain glucose-coated Cu9 S 5 , after natural cooling, centrifugal c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com