Induction cooker face shell machining device

A technology of processing device and induction cooker, which is applied in spraying device, metal processing equipment, grinding/polishing safety device, etc., can solve the problems that the product does not meet the requirements of aesthetics, the practicability is not strong, and the surface shell of the induction cooker is not installed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

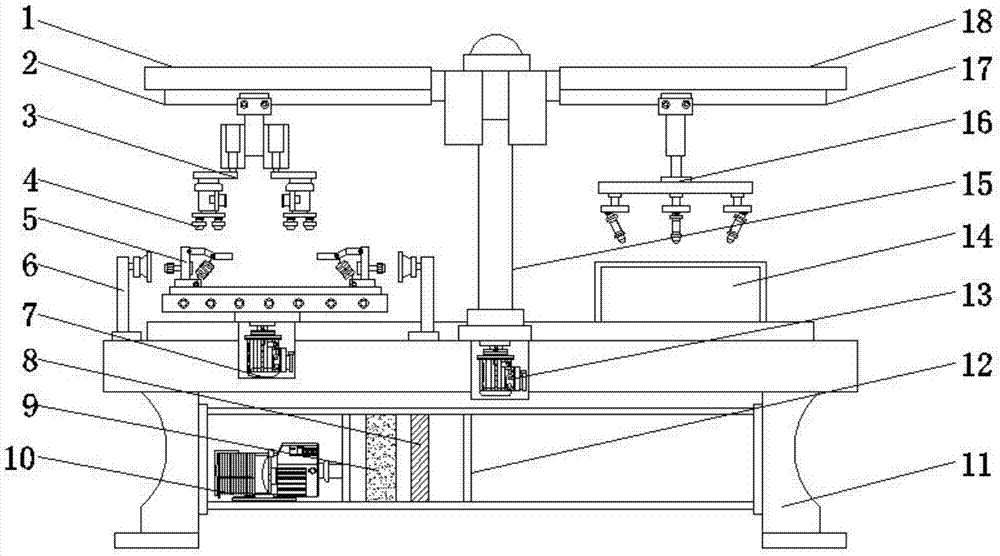

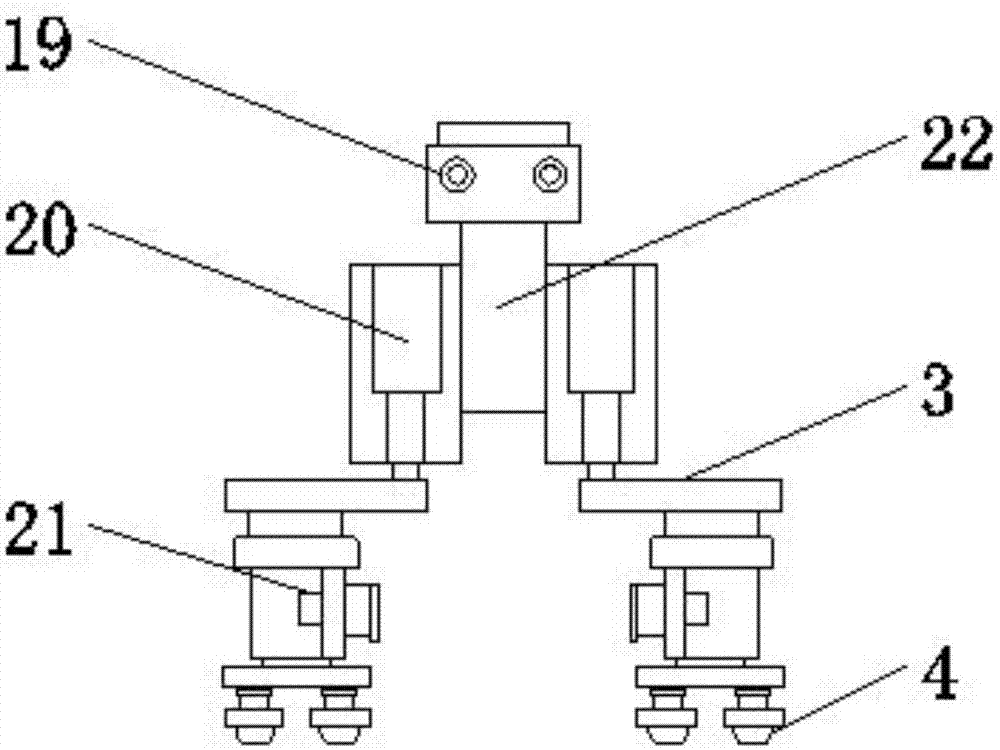

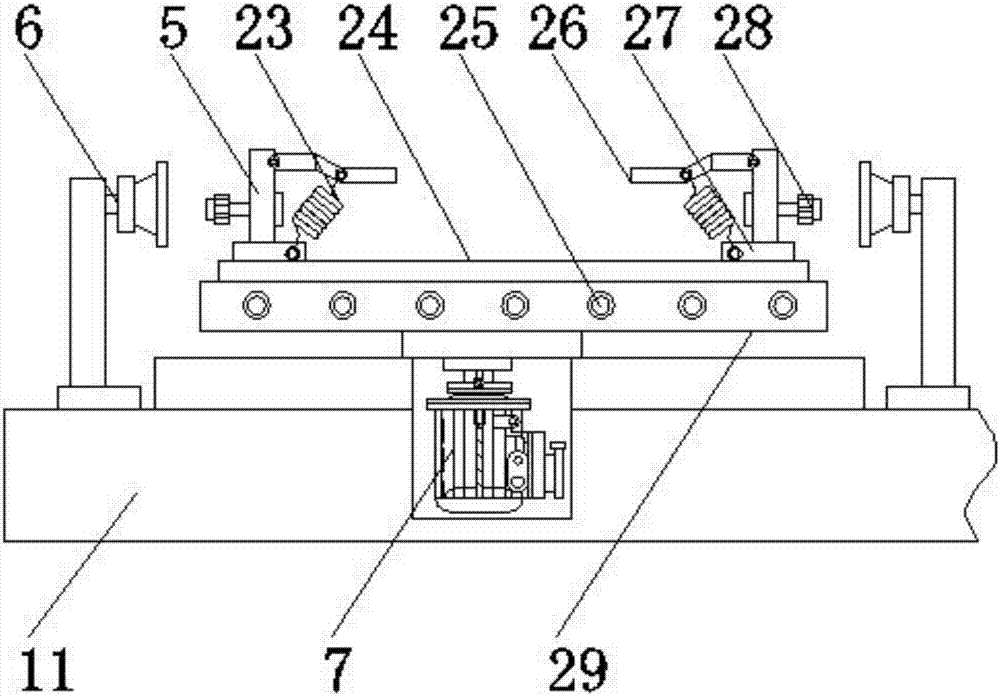

[0022] Such as Figure 1 to Figure 7As shown, a surface shell processing device for an electromagnetic oven includes a grinding head 4, a steel frame base 11, a mounting disc 29 and a paint spray gun head 34, and a dust suction pump 10 is installed at the bottom end of the steel frame base 11, and the dust suction pump An impurity treatment box 12 is installed inside the steel frame base 11 on one side of 10, and one end of the impurity treatment box 12 close to the dust collection pump 10 is connected to the output end of the dust collection pump 10 through a hose, and the inside of the impurity treatment box 12 is close to the dust collection pump 10 One side of the activated carbon adsorption layer 9 is fixed, and the filter screen 8 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com