Preparation method of manganese oxide-carbon nano fibrous composite catalytic membrane

A technology of carbon nanofibers and catalytic membranes, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., to achieve strong controllability, improve ozone utilization rate, and excellent catalysis The effect of ozone oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A MnO 2 Preparation method of / CNF composite catalytic membrane:

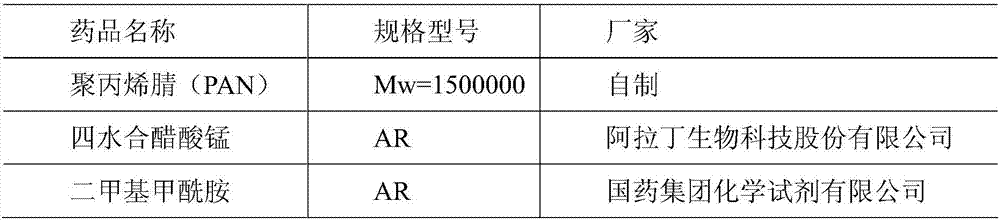

[0033] Step 1: Configuration of the casting solution

[0034] 4.8 g of polyacrylonitrile (PAN) was weighed and dispersed in 55.2 g of DMF, and stirred uniformly at room temperature. Then, 10wt%, 20wt% and 30wt% of PAN manganese acetate tetrahydrate were respectively added in the continuous stirring process, fully stirred to a dark red homogeneous film casting solution, and left to stand for defoaming.

[0035] Step 2: Mn(oAc) 2 Preparation of / PAN nanofiber composite membrane

[0036] The casting solution obtained in step 1 was injected into the electrospinning equipment, the spinning voltage was 16kv, the distance between the spinneret and the negative receiver was 15cm, the spinning solution pushing rate was 1.0ml / min, and the spinning temperature was 30 ℃, through the action of high-voltage electric field, the film was formed by jet spinning, and Mn(oAc) was obtained after drying at 50 ℃ for 12 ho...

Embodiment 2

[0042] The casting solution was prepared by adding 4.8g of polyacrylonitrile (PAN) and 55.2g of DMF into a stirring tank, mixing and stirring thoroughly, setting the temperature at 20°C, and stirring for 6 hours to obtain a uniform polymer casting solution. Add 30wt% PAN manganese acetate tetrahydrate to the continuously stirred polymer casting solution, set the temperature at 20° C., stir for 4 hours to obtain a homogeneous dark red transparent casting solution, and let stand for defoaming.

[0043] Spinning to form a film, inject the casting solution prepared in step 1 into the electrospinning spinning propeller, set the spinning propulsion rate to 0.6ml / min, the spinning voltage to 16kv, and the distance between the spinneret and the negative electrode receiver to be 15cm, the spinning temperature is 30°C, through the action of high-voltage electric field, jet spinning to form a film, set the oven temperature to 50°C, and dry for 12h to obtain Mn(oAc) 2 / PAN nanofiber compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com