High-efficient physical antifreezing agent for tea planting

A high-efficiency antifreeze technology, applied in plant protection, botany equipment and methods, applications, etc., can solve problems such as high labor intensity and tea tree damage, and achieve the goal of avoiding economic losses, reducing adverse effects, and high-efficiency antifreeze performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

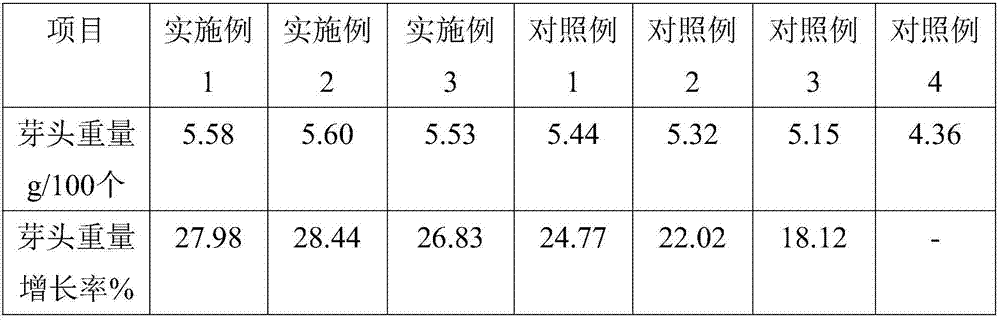

Examples

Embodiment 1

[0022] (1) Heat 5g of anionic polyacrylamide to 115-125°C and mix for 10 minutes, then add 0.5g of polydimethyldiallylammonium chloride and 0.1g of nano-zinc oxide, and continue to mix at 115-125°C for 30 minutes , cooled naturally to room temperature under grinding to obtain modified polyacrylamide;

[0023] (2) Add 20g of hydroxypropyl methylcellulose / polyaspartic acid, 5g of hydroxypropyl distarch phosphate and modified polyacrylamide to 250g of water, heat to reflux state and mix for 15min, then add 3g of zeolite powder and 0.5 g of tea seed powder, continue to reflux and heat-preserve and mix for 15 minutes, transfer the resulting mixture to a ball mill while hot, and ball mill until the fineness is less than 30 μm, to obtain the antifreeze agent.

[0024] Preparation of hydroxypropyl methylcellulose / polyaspartic acid: add deionized water dropwise to 10g polyaspartic acid under grinding until it is completely dissolved, and add 10% dilute hydrochloric acid dropwise to adj...

Embodiment 2

[0027] (1) Heat 3g of anionic polyacrylamide to 115-125°C and mix for 5 minutes, then add 0.5g of polydimethyldiallylammonium chloride and 0.05g of nano-zinc oxide, and continue to mix at 115-125°C for 30 minutes , cooled naturally to room temperature under grinding to obtain modified polyacrylamide;

[0028] (2) Add 15g of hydroxypropyl methylcellulose / polyaspartic acid, 3g of hydroxypropyl distarch phosphate and modified polyacrylamide to 200g of water, heat to reflux state and mix for 10min, then add 2g of zeolite powder and 0.3g of tea seed powder, continue to reflux and heat-preserve and mix for 10 minutes, transfer the resulting mixture to a ball mill while hot, and ball mill until the fineness is less than 30 μm to obtain the antifreeze agent.

[0029] Preparation of hydroxypropyl methylcellulose / polyaspartic acid: under grinding, add deionized water dropwise to 15g polyaspartic acid until it is completely dissolved, and add 10% dilute hydrochloric acid dropwise to adju...

Embodiment 3

[0032] (1) Heat 3g of anionic polyacrylamide to 115-125°C and mix for 5 minutes, then add 0.5g of polydimethyldiallylammonium chloride and 0.05g of nano-zinc oxide, and continue to mix at 115-125°C for 30 minutes , cooled naturally to room temperature under grinding to obtain modified polyacrylamide;

[0033] (2) Add 15g of hydroxypropyl methylcellulose / polyaspartic acid, 3g of hydroxypropyl distarch phosphate and modified polyacrylamide to 200g of water, heat to reflux state and mix for 10min, then add 2g of zeolite powder and 0.3g of tea seed powder, continue to reflux and heat-preserve and mix for 10 minutes, transfer the resulting mixture to a ball mill while hot, and ball mill until the fineness is less than 30 μm to obtain the antifreeze agent.

[0034]Preparation of hydroxypropyl methylcellulose / polyaspartic acid: under grinding, add deionized water dropwise to 15g polyaspartic acid until it is completely dissolved, and add 10% dilute hydrochloric acid dropwise to adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com