Method and Terminal for Realizing Shell Surface Texture

A surface texture and shell technology, applied in the field of shell surface texture, can solve the problems that cannot be applied to metal shells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

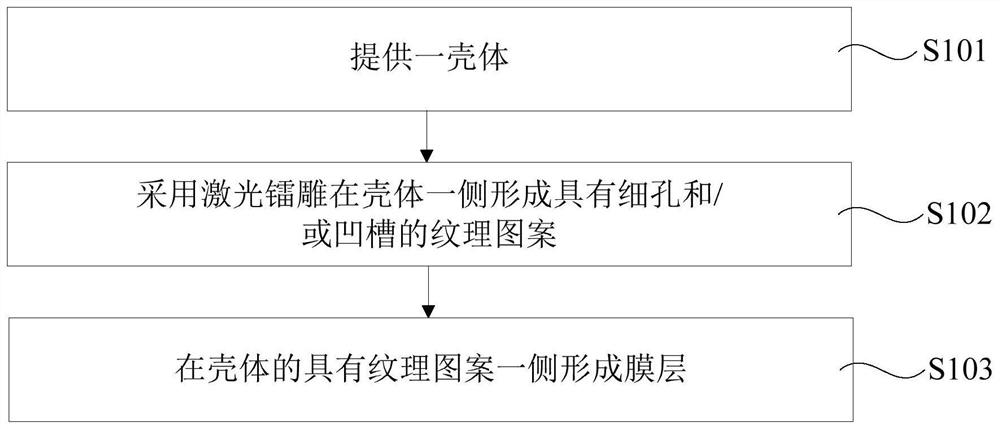

[0022] see figure 1 , is a schematic flowchart of an embodiment of the method for realizing the surface texture of the shell in the present invention. The method includes:

[0023] S101: Provide a casing.

[0024] Optionally, the casing may be a mobile terminal such as a mobile phone, a computer, or an Ipad, or a casing of other wearable devices.

[0025] Optionally, the shell is made of metal or alloy. In other embodiments, the housing can also be made of other materials such as plastic.

[0026] S102: Forming a texture pattern with fine holes and / or grooves on one side of the casing by laser engraving.

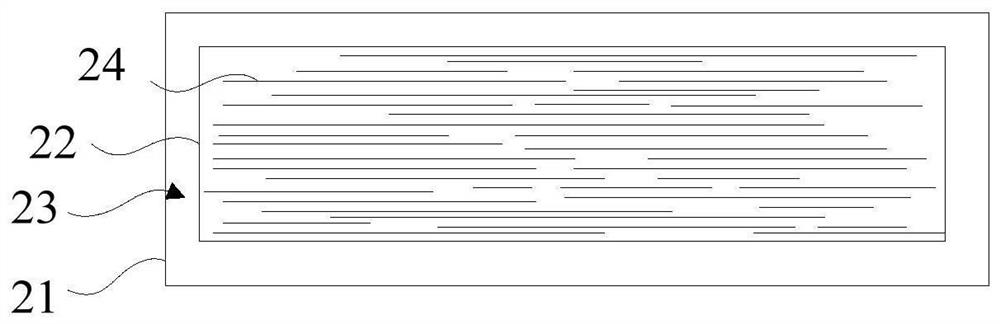

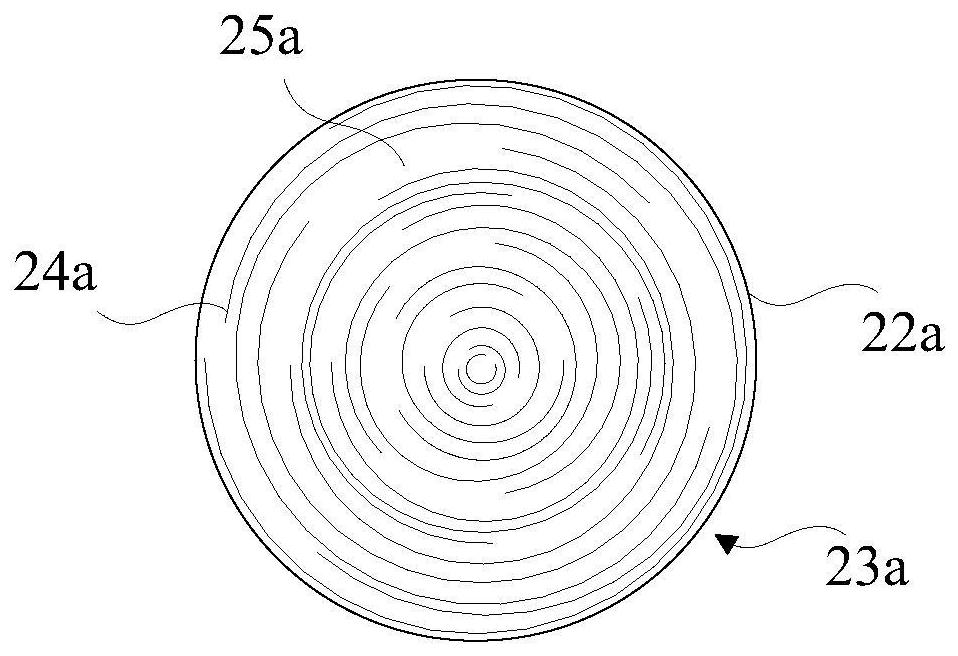

[0027] Specifically, the side of the laser engraving is the side facing the user, so as to present the texture pattern to the user. Optionally, laser radium engraving adopts laser wavelength 266-1064nm, working current 7-18A, and power density...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com