Preparation method and application of self-support flexible electrode

A flexible electrode, self-supporting technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of complex preparation process of conductive carbon nanomaterials, easy pulverization of flexible electrodes, etc., to achieve easy shape design and assembly, and environmental friendliness , excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

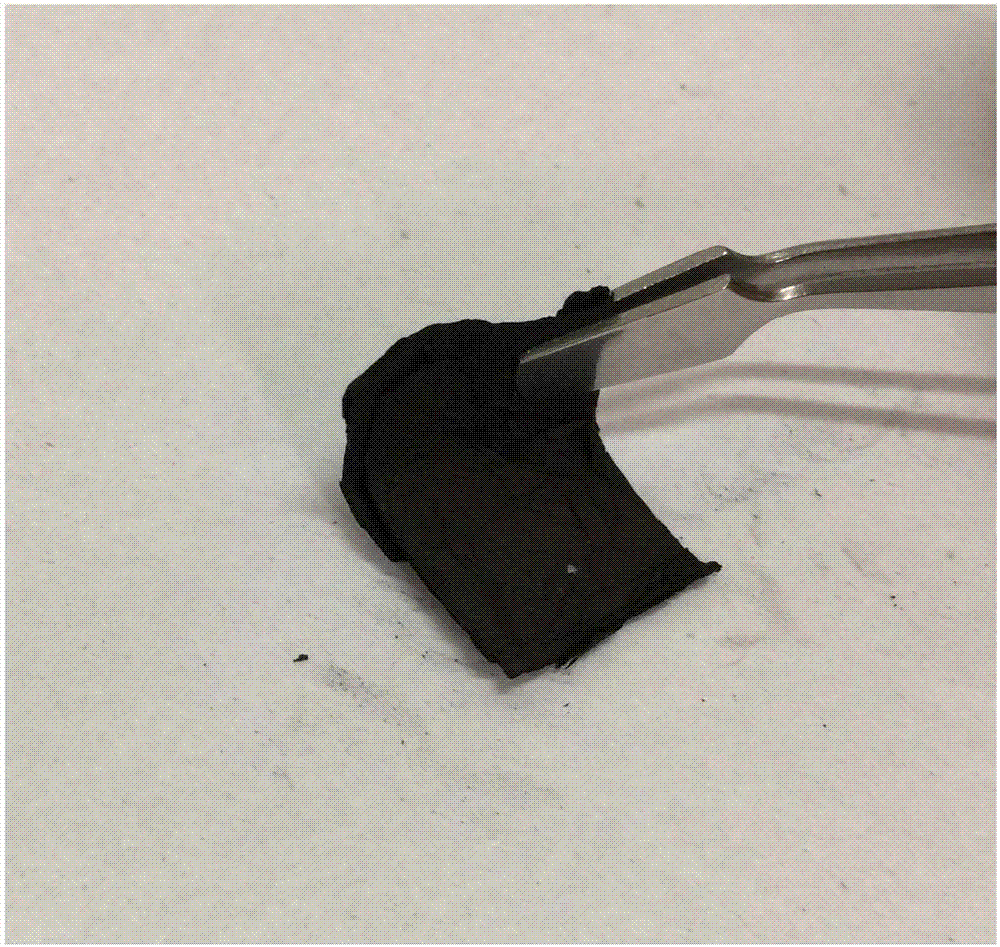

[0023] Get 0.8 grams of tin dichloride (SnCl 2 2H 2 O) and 0.5 g of polyvinylpyrrolidone (PVP) were dissolved in a mixed solvent consisting of 5 g of dimethylformamide (DMF) and 5 g of ethanol to form a 'nuclear' solution; 0.5 g of polyacrylonitrile (PAN) was dissolved The 'shell' solution was prepared in 5 grams of dimethylformamide (DMF); the above two solutions were used as the 'core' and 'shell' solutions respectively for coaxial electrospinning, and the coaxial electrospinning voltage was 15kV. The collection distance is 15 cm. The collected film was heat-treated at 250°C for 2 hours under a high-purity nitrogen atmosphere, then raised to 650°C for 2 hours, and cooled to room temperature to obtain a black self-supporting flexible electrode. The self-supporting flexible electrode prepared by the invention can withstand repeated bending deformation and can be directly cut and processed. Its shape and flexibility are as figure 1 shown.

Embodiment 2

[0025] Take 1.0 g of tin dichloride (SnCl 2 2H 2 O) and 0.5 g of polyvinylpyrrolidone (PVP) were dissolved in a mixed solvent consisting of 5 g of dimethylformamide (DMF) and 5 g of ethanol to form a 'nuclear' solution; 0.5 g of polyacrylonitrile (PAN) was dissolved The 'shell' solution was prepared in 4.5 grams of dimethylformamide (DMF); the above two solutions were respectively used as the 'core' and 'shell' solutions for coaxial electrospinning, and the coaxial electrospinning voltage was 15kV. The collection distance is 15 cm. The collected film was heat-treated at 250°C for 2 hours in a high-purity nitrogen atmosphere, then raised to 700°C for 2 hours, and cooled to room temperature to obtain a black self-supporting flexible electrode.

Embodiment 3

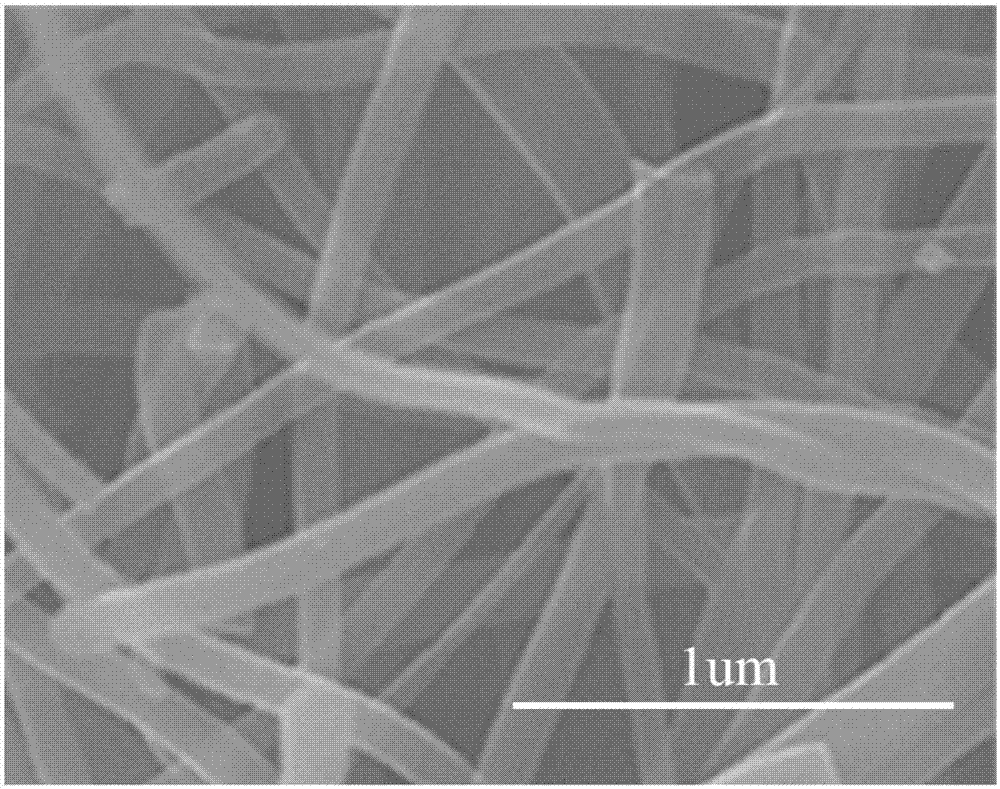

[0027] Get 0.8 grams of tin dichloride (SnCl 2 2H 2 O) and 0.5 g of polyvinylpyrrolidone (PVP) were dissolved in a mixed solvent consisting of 5 g of dimethylformamide (DMF) and 5 g of ethanol to form a 'nuclear' solution; 0.5 g of polyacrylonitrile (PAN) was dissolved The 'shell' solution was prepared in 5 grams of dimethylformamide (DMF); the above two solutions were used as the 'core' and 'shell' solutions respectively for coaxial electrospinning, and the coaxial electrospinning voltage was 15kV. The collection distance is 15 cm. The collected film was heat-treated at 250°C for 2 hours under a high-purity nitrogen atmosphere, then raised to 650°C for 3 hours, and cooled to room temperature to obtain a black self-supporting flexible electrode. The self-supporting flexible electrode prepared by the present invention is completely composed of nanofibers, with a microstructure such as figure 2 shown. Inside the fiber are tin dioxide nanofibers, and the outer layer is a car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com