Air tightness detection device

An air tightness detection and to-be-detected technology, which is used in measuring devices, fluid tightness testing, and liquid tightness measurement using liquid/vacuum degree. Difficulties and other problems, to achieve the effect of high detection efficiency and reduce worker fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

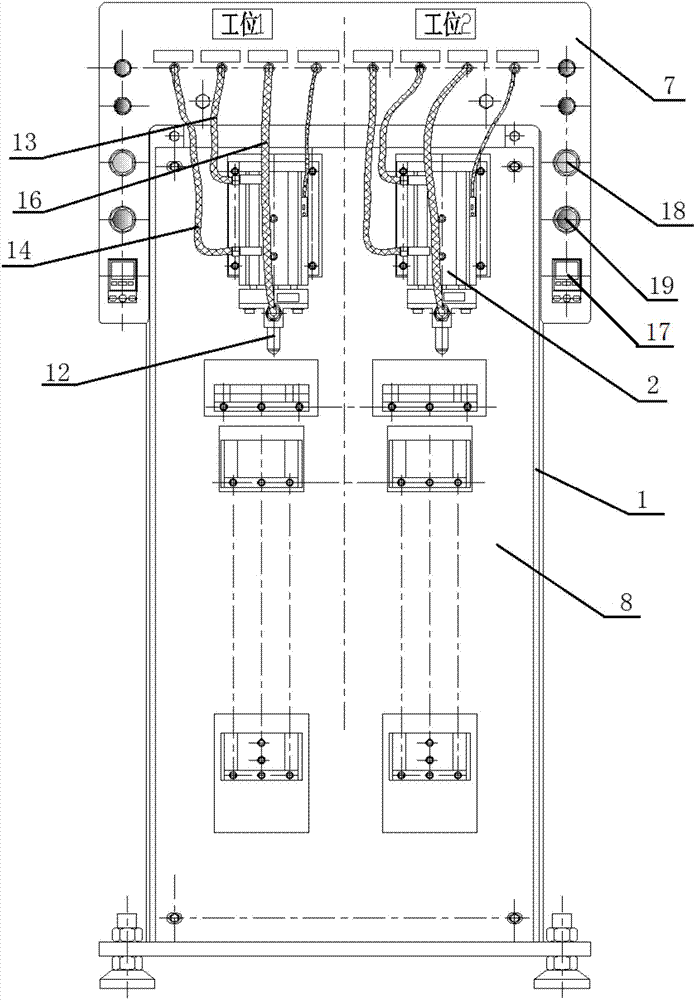

[0021] This embodiment provides a multi-station air tightness detection device, which can realize automatic pressure charging, pressure maintaining and detection of multiple devices to be tested at the same time, thereby effectively improving the detection efficiency.

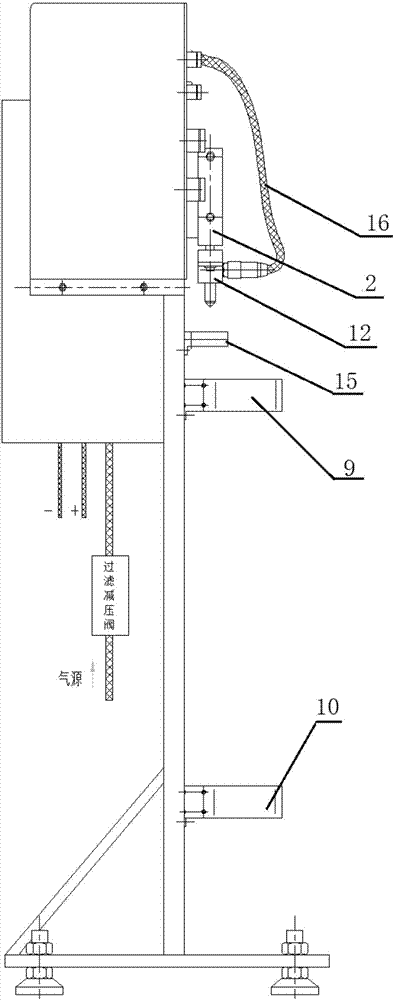

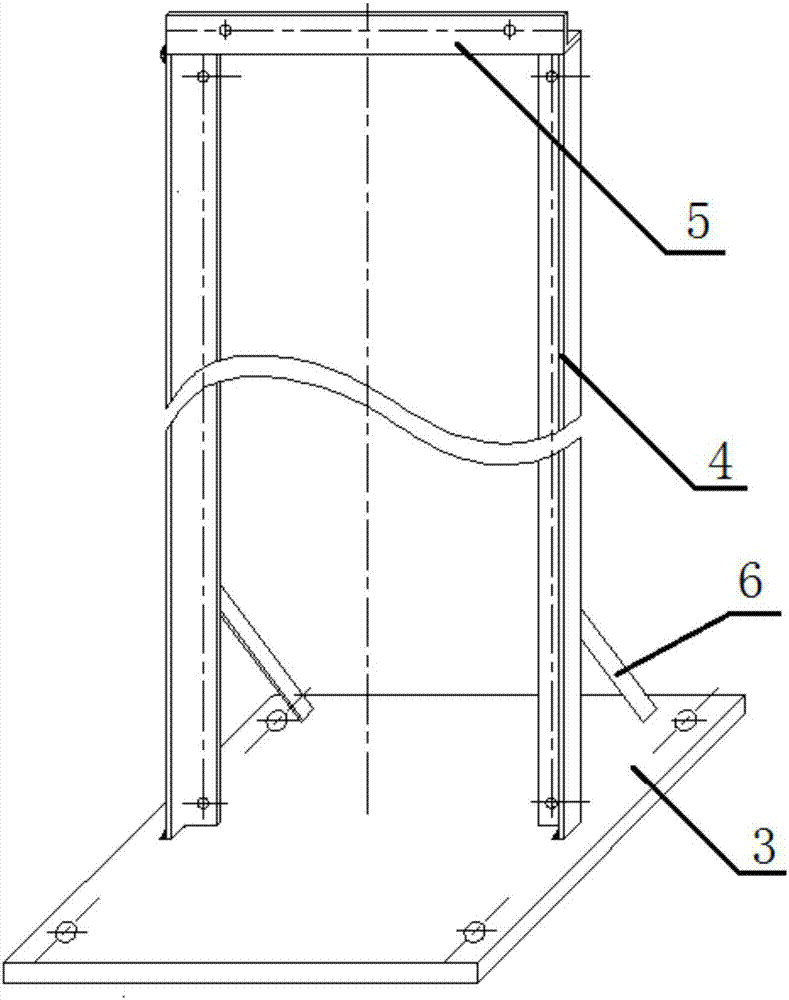

[0022] Such as figure 1 and figure 2 As shown, the airtightness detection device includes: a frame 1, an airtight structure, an air circuit unit and a control unit. This embodiment is a double-station air-tightness detection device, that is, two stations are provided, and the air-tightness detection can be performed on two cylinders to be tested (in this embodiment, the equipment to be tested is a cylinder). The two stations share the frame 1 and the control unit, and each station has an independent airtight structure and air circuit unit. The airtight structure includes the cylinder 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com